17

TIG WELDING

• ARC FORCE (0 ÷ 100): this

increases the energy of the arc on

poor welding conditions

• PRINCIPAL weld CURRENT

I

1

(5 ÷

250 A)

4)

Keep pressing the

SET

key for about 1 second

to leave the weld

parameter setting

phase

• The GREEN LIGHT

I

1

is on

5)

It is now ready for welding

6)

The digital display visu-

alizes effective current

used during welding

1)

Start up the welder by turning the

main switch to position

I

2)

Press the "weld process" button and

set on:

•

TIG "HF"

for TIG weld

with high frequency arc

strike

OR

•

TIG

tipo

“lift”

per la sal-

datura TIG tipo

“lift”

senza alta frequenza

WARNING:

The correct "lift" type arc

strike is only obtained by pressing the

torch button after touching the piece to

be welded with the electrode befo-

rehand.

3)

Press the "weld mode" button and

set on one of the 4 options availa-

ble:

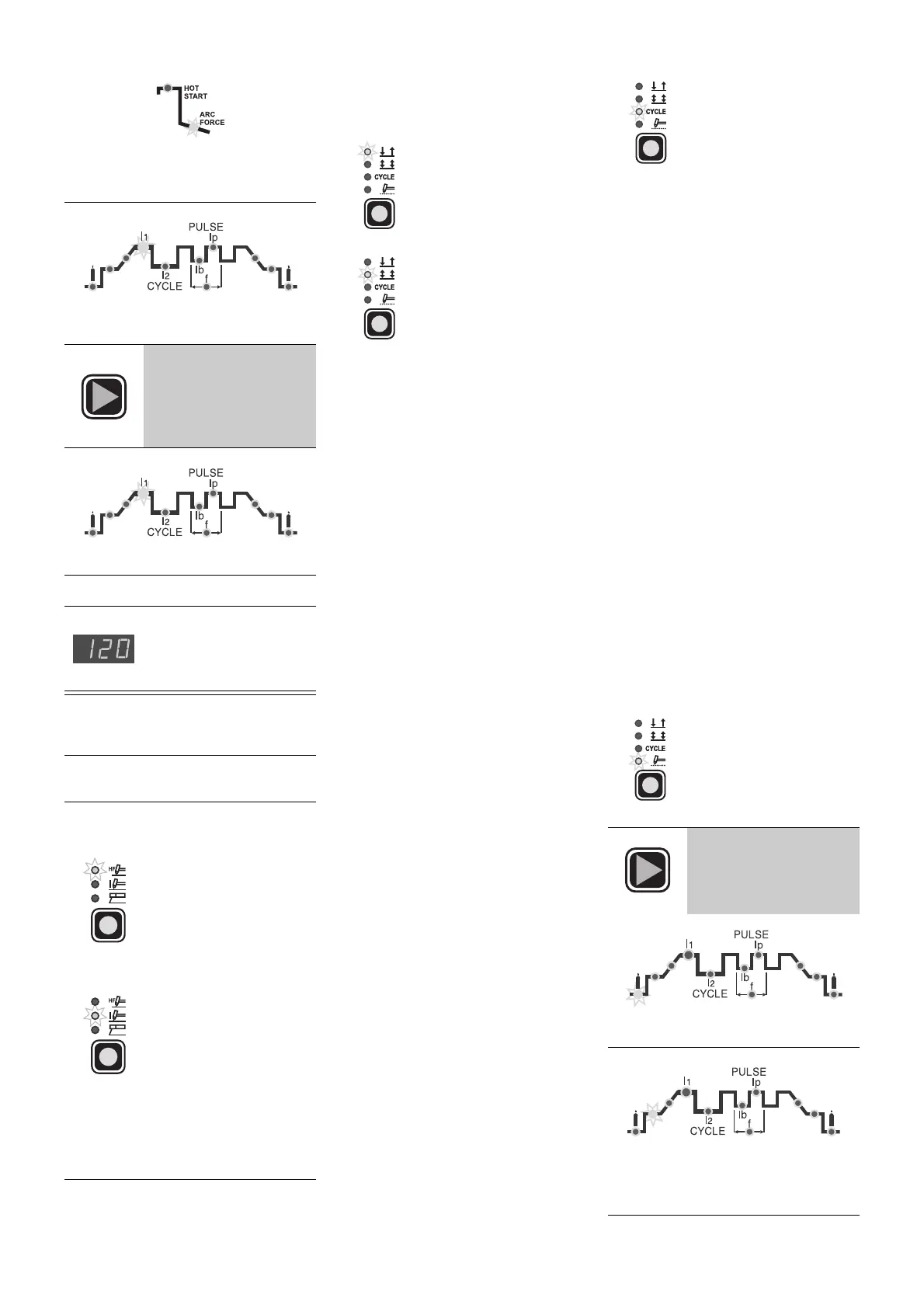

•

2 STROKE

The TIG weld cycle is

done by pressing the

torch button, while weld-

ing will stop when you

release it.

•

4 STROKE

TIG welding is done as

follows:

A)

Pressing the torch

button strikes up the

arc and the current

stays at the INITIAL

value

B)

Peleasing the torch

button will start the

SLOPE UP (if

present) and the

PRINCIPAL CUR-

RENT will take itself

to value

I

1

C)

Pressing the torch

button will start the

SLOPE DOWN (if

present) and the cur-

rent will take itself to

the FINAL value

(crater current)

D)

Releasing the button

will finish the weld

cycle.

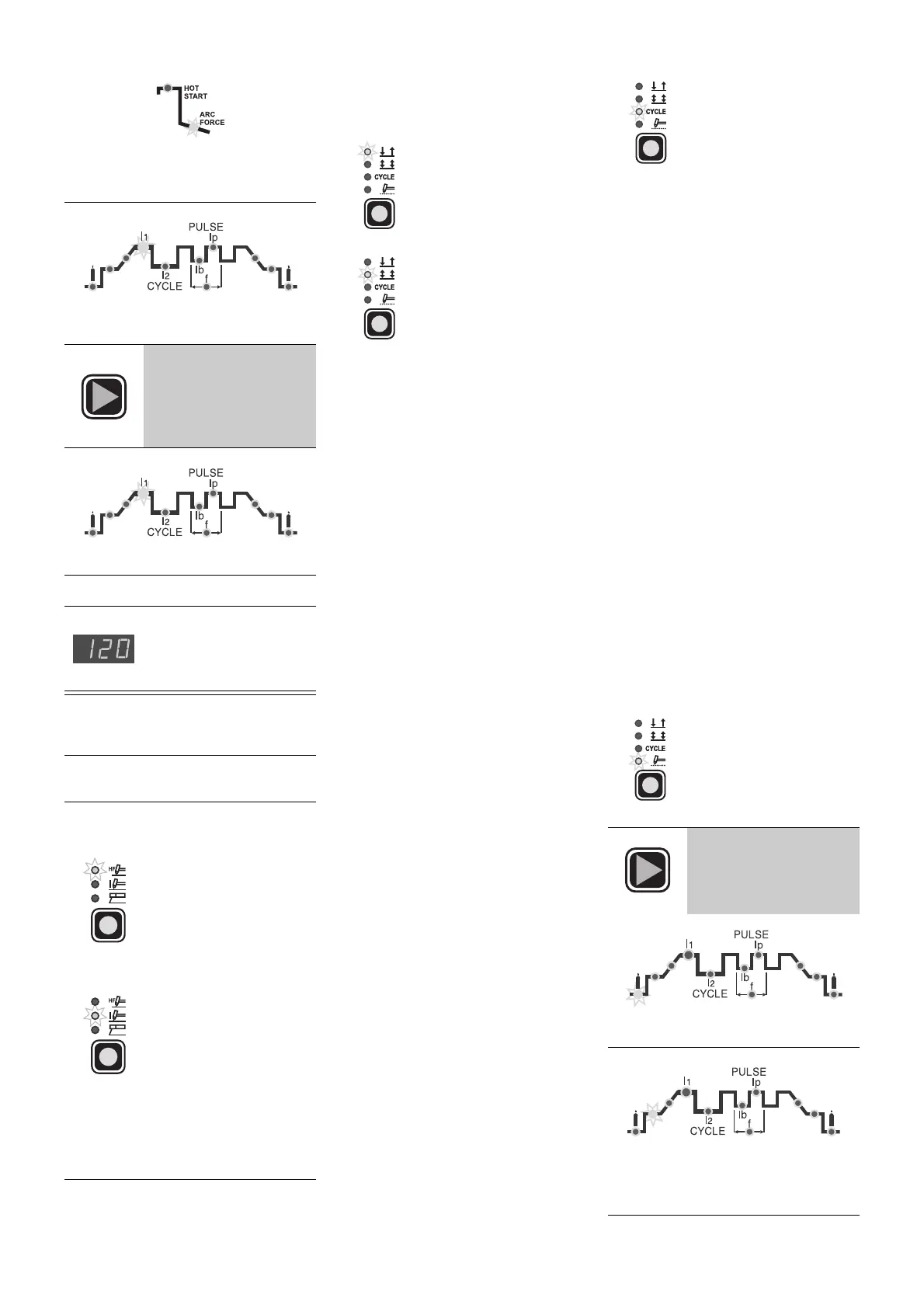

•

CYCLE

TIG welding is done as

follows with this function

on:

• pressing the torch but-

ton will strike up the

arc and the current

stays at the INITIAL

value

• releasing the torch

button will start the

SLOPE UP (if present)

and the current will

take itself to the PRIN-

CIPAL value (

I

1

)

• pressing and releasing

the torch button for

less than 1 second,

the weld current will

take itself to the

CYCLE (

I

2

) value; it

will be possible to

move an infinite

number of times

between the two cur-

rent levels (

I

1

,

I

2

) by

repeating this opera-

tion

• pressing the torch but-

ton and keeping it

pressed down (for

more than 2 seconds)

will start the SLOPE

DOWN (if present)

and the current will

take itself to the FINAL

value (crater current)

• releasing the torch

button will finish the

weld cycle

•

SPOT-WELDING

Spot-welding can be

done for the set time (in

seconds) by pressing

the torch button after

which the arc will auto-

matically switch off

4)

The following weld

parameters can be set

by pressing the

SET

button repeatedly

PRE-GAS time (0,05 ÷ 1 sec)

INITIAL weld CURRENT (5 ÷ 250 A)

WARNING:

only programmable with

4

STROKE

or

CYCLE

functions on

Loading...

Loading...