Condensing Pool Heater Genie S

Winterisation

Turn off the Mains electricity and Gas Supply.

As supplied the Heater includes one litre of Sentinel

X500 Inhibitor/Anti-freeze, this is suffi cient to protect

the Heater down to -10°C. It is recommended that

this is maintained and so should be replenished if

there is a loss of primary water. See Fig 14.0

Draining the Heater can be achieved by fi tting the

drain assembly in place of the double check valve/

hose connector. The Condensate Syphon can be

drained by removal of its Drain Cap. See Fig 7.1

Electricity Supply

Wiring external to the appliance MUST be in accord-

ance with the current I.E.T. Wiring Regulations and

any Local Regulations that apply.

The Heater is supplied with a plug and lead for 230V

~ 50Hz. Single phase. Fuse rating is 5A.

The method of connection to the mains electricity

supply MUST facilitate complete electrical isola-

tion of the Heater, preferably by the use of a fused

double pole switch having a 3mm (1/8in.) contact

separation in both poles and servicing only the

Heater and its controls.

The point of connection to the mains should be

readily accessible and adjacent to the Heater.

Where a Heater is installed in a room

containing a pool or shower, the appliance,

any electrical switch or appliance control

utilising mains electricity should be so

situated that it cannot be touched.

6

Condensate Drain

See Fig. 7.0, and 7.1

A 75mm condensate trap is provided on the Heater

and is satisfactory when connected to Soakaways,

Gullies, Rainwater Pipework and Internal Drainage

systems. All pipework and fi ttings in the condensate

drainage system MUST be made of plastic, unless

they carry other liquid waste. No other materials

may be used. The pipework should be insulated if

run out of doors.

The drain outlet on the boiler is :

40 mm Hunter waste pipe.

Pool Pump & Pipe work

The Heater is an indirect design and uses two very

high performance heat exchangers. The pool water

passes through the Secondary, the water in the

Primary is completely separate. The Heaters con-

trols modulate the input when approaching the set

temperature for greater accuracy and economy. It

is recommended that pool pump overrun is used to

maximise the life of the Heater.

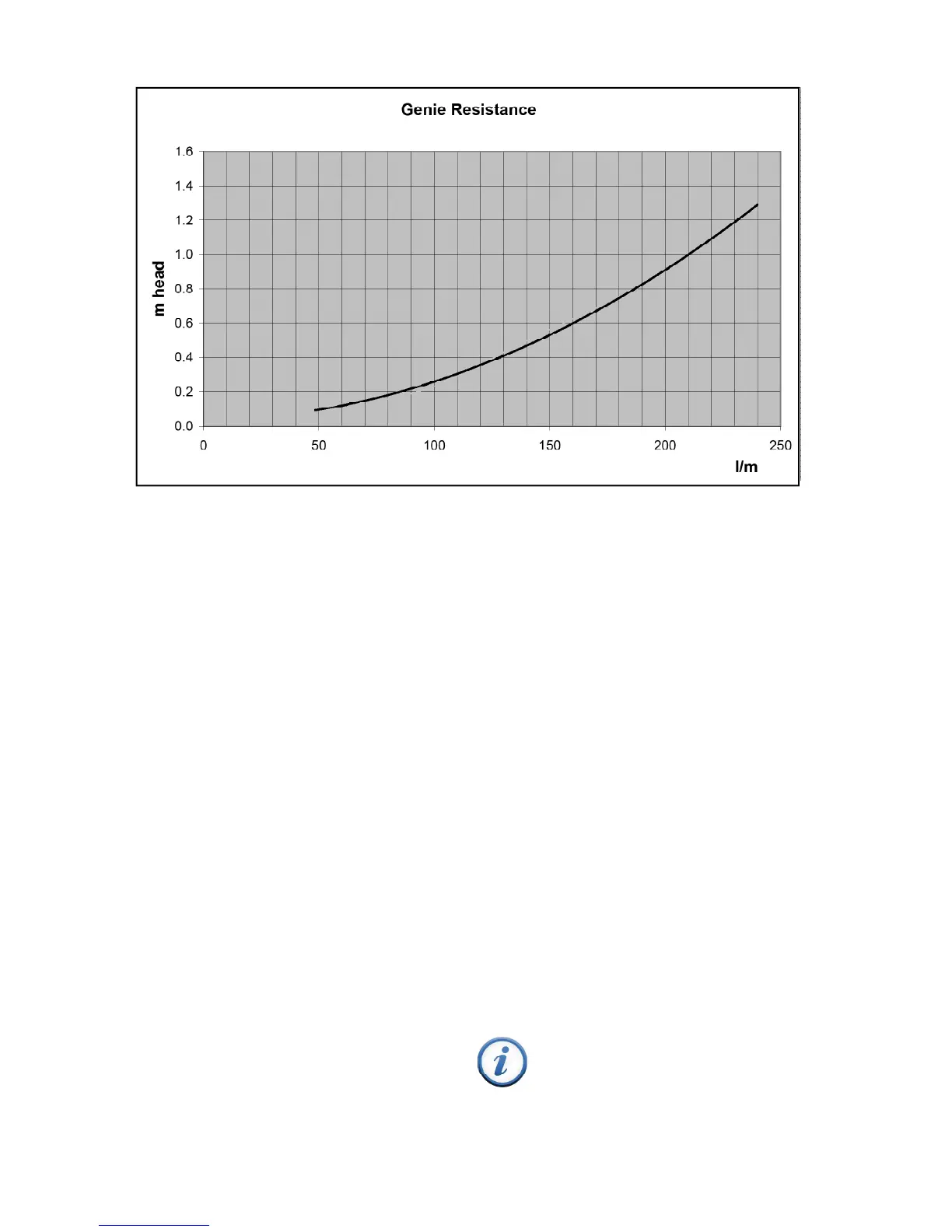

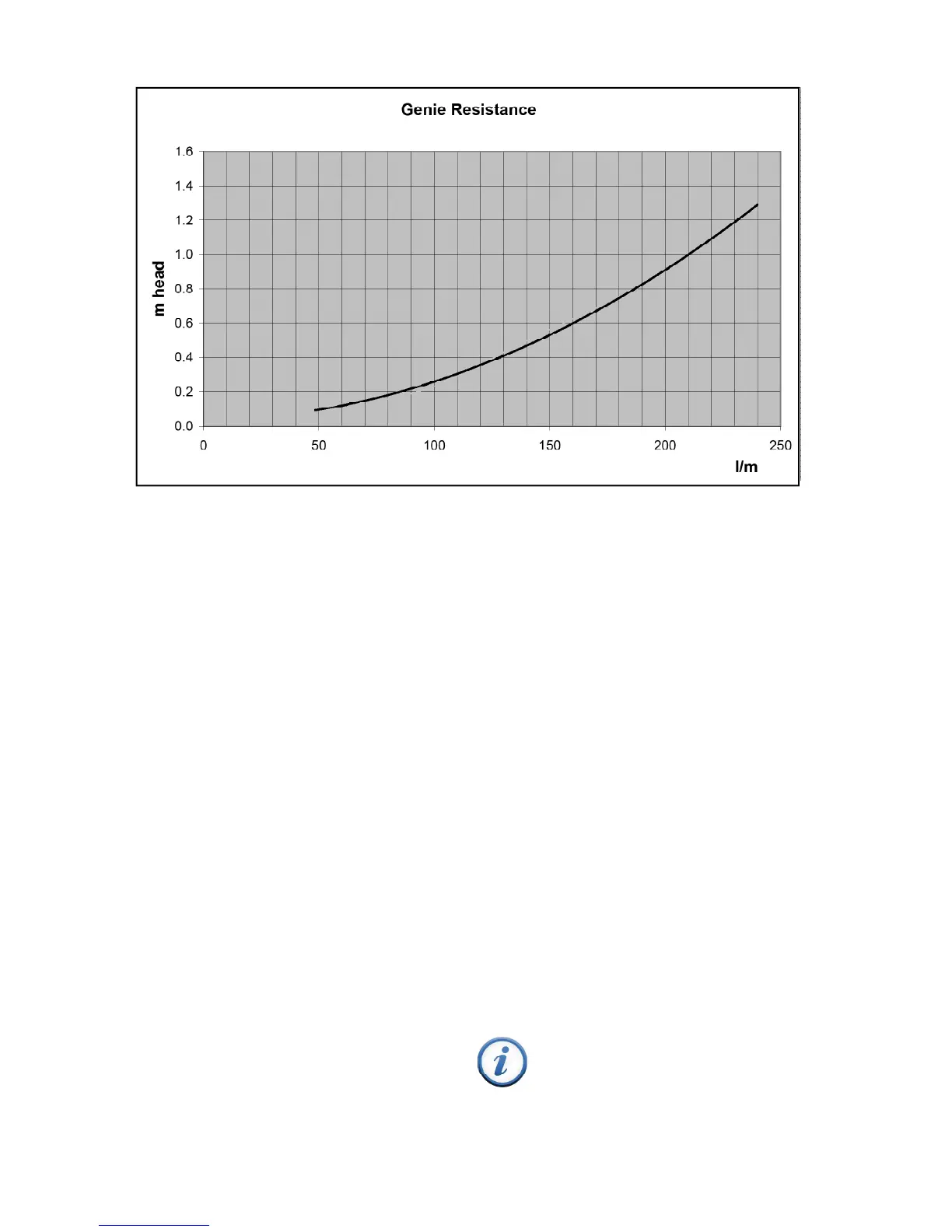

If a new pump is being fi tted consult the Pressure

Loss graph (Fig 2.0) to determine its size.

The Heater is provided with both 1½” and 50mm

plastic pool connections. As built the connections

are ‘From Pool’ on the left, ‘To Pool’ on the right,

however these can be easily reversed.

With the exception of automatic dosing equipment,

the Heater should be plumbed as the last piece of

equipment before the pool.

It is permissible to fi t an isolating valves on the pipe-

work on either side of the Heater. In these circum-

stances it is recommended to fi t a fl ow switch in the

Heaters Mains supply.

Fig. 2.0

Loading...

Loading...