K

p

K

i

K

d

Process

Variable

Error

Integral

Derivave

Output

85

4.6 Transducer Calibraon

Follow these steps to calibrate a transducer:

Idenfy the transducer output type.

Note: The ARControl can read Barksdale 422 series, mV/V, Raometric, 1-5V, and 4-20mA output type

transducers. The ARControl BMS provides non-incenve connecons for external Barksdale 422-series pressure

transducers. These transducers have been evaluated as non-incenve in this applicaon. They contain only a

resisve bridge without any capacitance or inductance.

1. Set the seng for SPAN:

a. Idenfy the output range of the transducer (e.g. -5 to 100 psi).

• Calculate the range (e.g. 100 psi -5 psi = 105 psi)

b. Determine the desired resoluon (e.g. 1 psi, 0.1 psi, 0.01 psi).

• Do not select a resoluon that is outside of the tolerance of the transducer

• The desired resoluon is the DECIMAL PLACE

c. Calculang XDCR

MAXOUTmV

(Note: Only applicable for mV/V transducers).

• Idenfy the maximum output of the transducer (located on label or datasheet)

• Convert this value to mV (millivolts) if some other unit e.g. 1.5V output = 1500mV; 10V = 10000mV

d. Ulizing the informaon from steps a through c, use the following equaons (Table 4.6.1) to calculate SPAN:

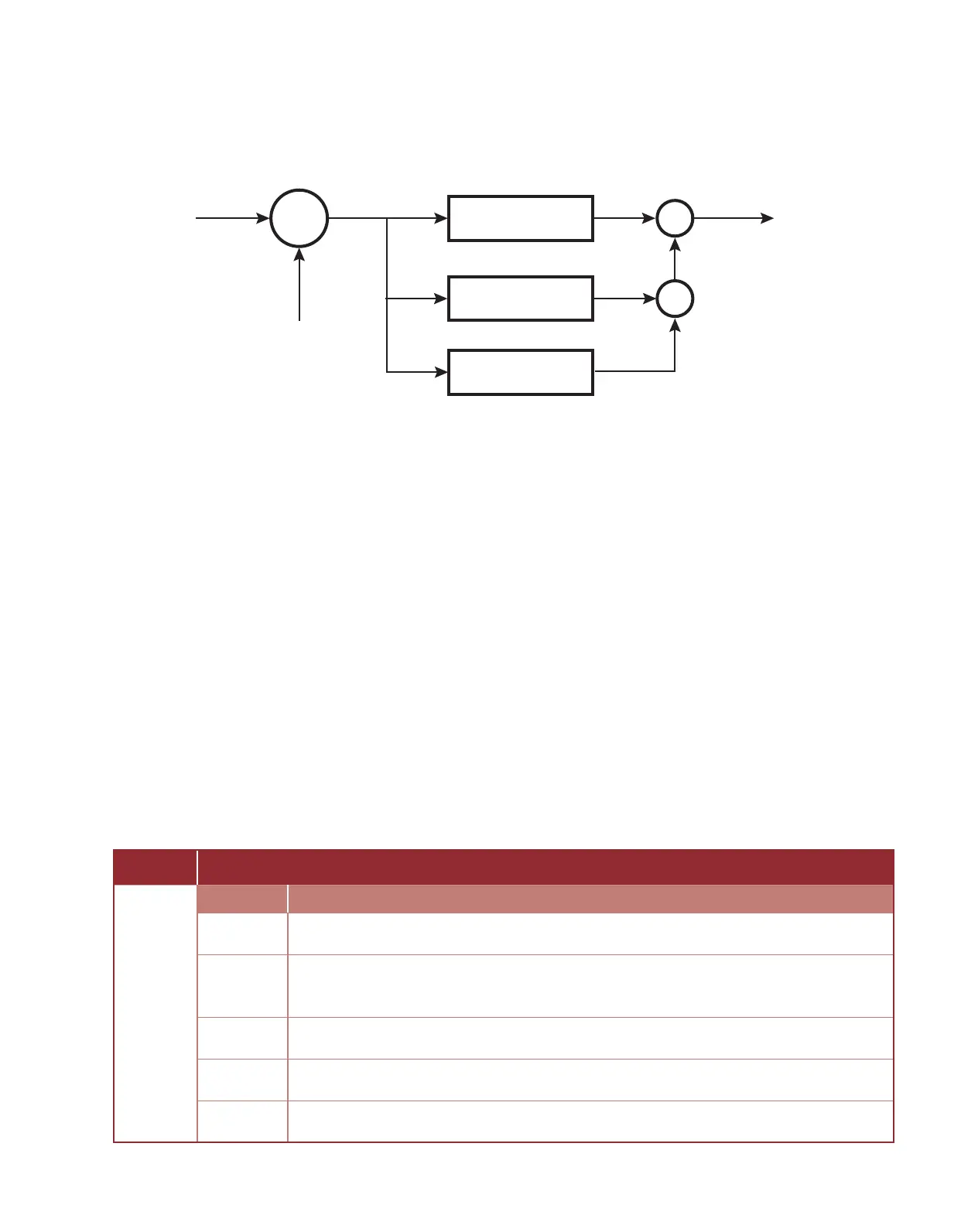

4.5 PID Control Loop

The system has a PID control loop which is ulized along with the accessory ARControl 4-20 mA module. The PID

controller allows for precise and stable closed-loop-control that is tolerant to system error. The PID controller requires

tuning which is best performed by personnel with PID tuning experience. The PID control loop runs at all mes, even in

DIAGNOSTIC mode.

Image 4.5.1 · PID control loop

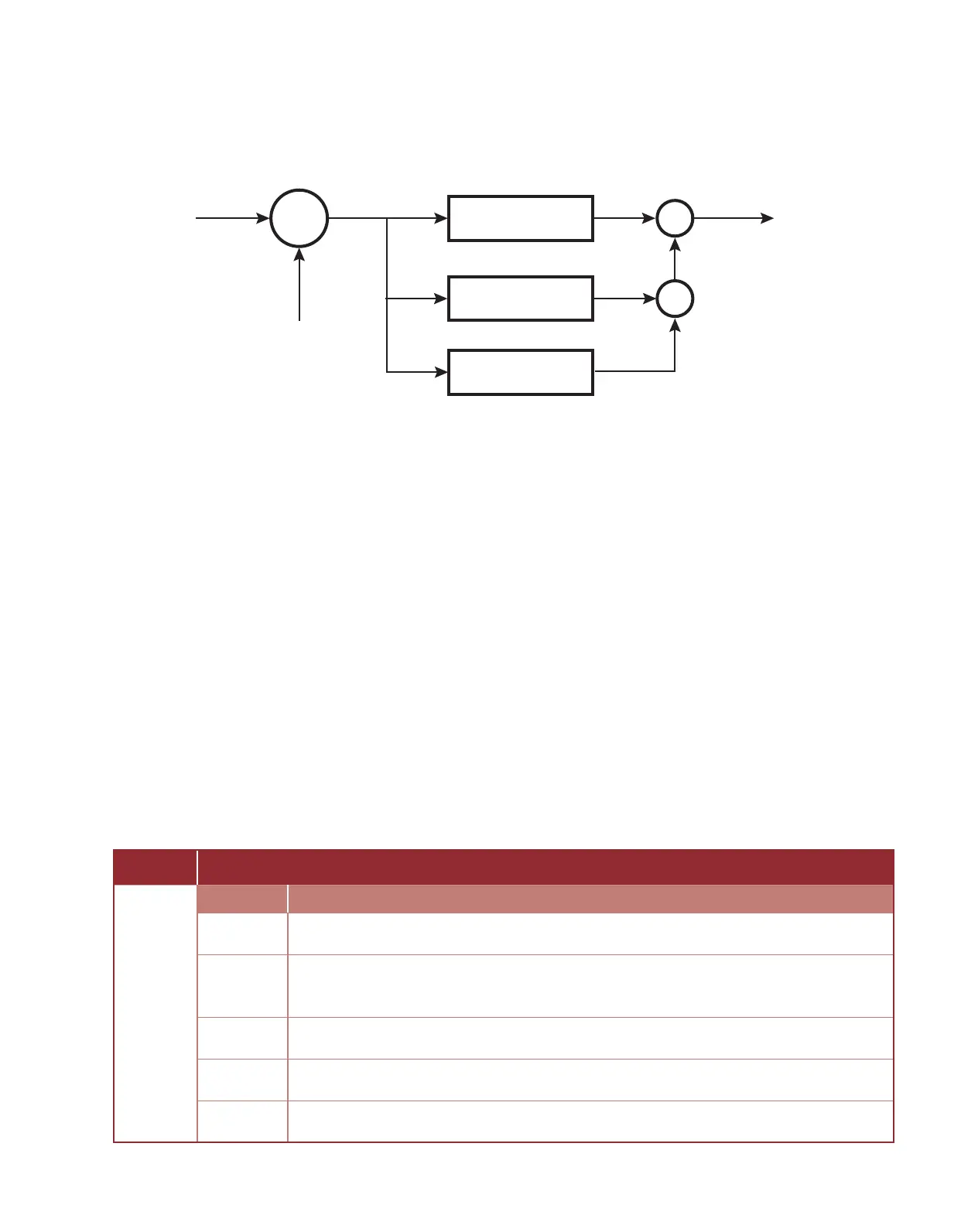

Table 4.6.1 · SPAN equaons

SETTING DESCRIPTION

SPAN

XDCR Type SPAN Calculaon

BK 422

Span = (RANGE

xdcr

) ∙ 10

DECIMAL PLACE

mV/V

Span = (XDCR

MAXOUTmV

/ 156.25mV) ∙ (RANGE

xdcr

) ∙ 10

DECIMAL PLACE

Rao

Span = (RANGE

xdcr

) ∙ 10

DECIMAL PLACE

1-5V

Span = (RANGE

xdcr

) ∙ 10

DECIMAL PLACE

4-20mA

Span = (RANGE

xdcr

) ∙ 10

DECIMAL PLACE

Loading...

Loading...