Model CFC ClearFire Commercial Boilers

21 Rev. 05-2012

(90.5 C) is set for normal boiler operation.

While proper overpressure is required, a means to relieve excess pressure at or

beyond the design pressure of the boiler must be provided. As boiler water is

heated, expansion occurs. And this expansion must be accounted for either with an

expansion tank (air filled) or with a bladder type tank. These devices permit the

water pressure to expand outside of the boiler and not impact the pressure vessel or

pressure relieving device. But, in accordance with Code, each boiler is equipped

with an ASME approved safety relieving device should pressure build-up occur (See

Table B5-16 and Table B5-15).

Air Venting The elimination of entrained air is required. It is recommended that each unit be

piped to an expansion tank. If this is not possible, then an auto air vent should be

provided on the vent connection of the boiler. The caveat in using an auto vent is

that free oxygen can be introduced to the vesel as the boiler cools, or in some

instances the vent can become plugged.

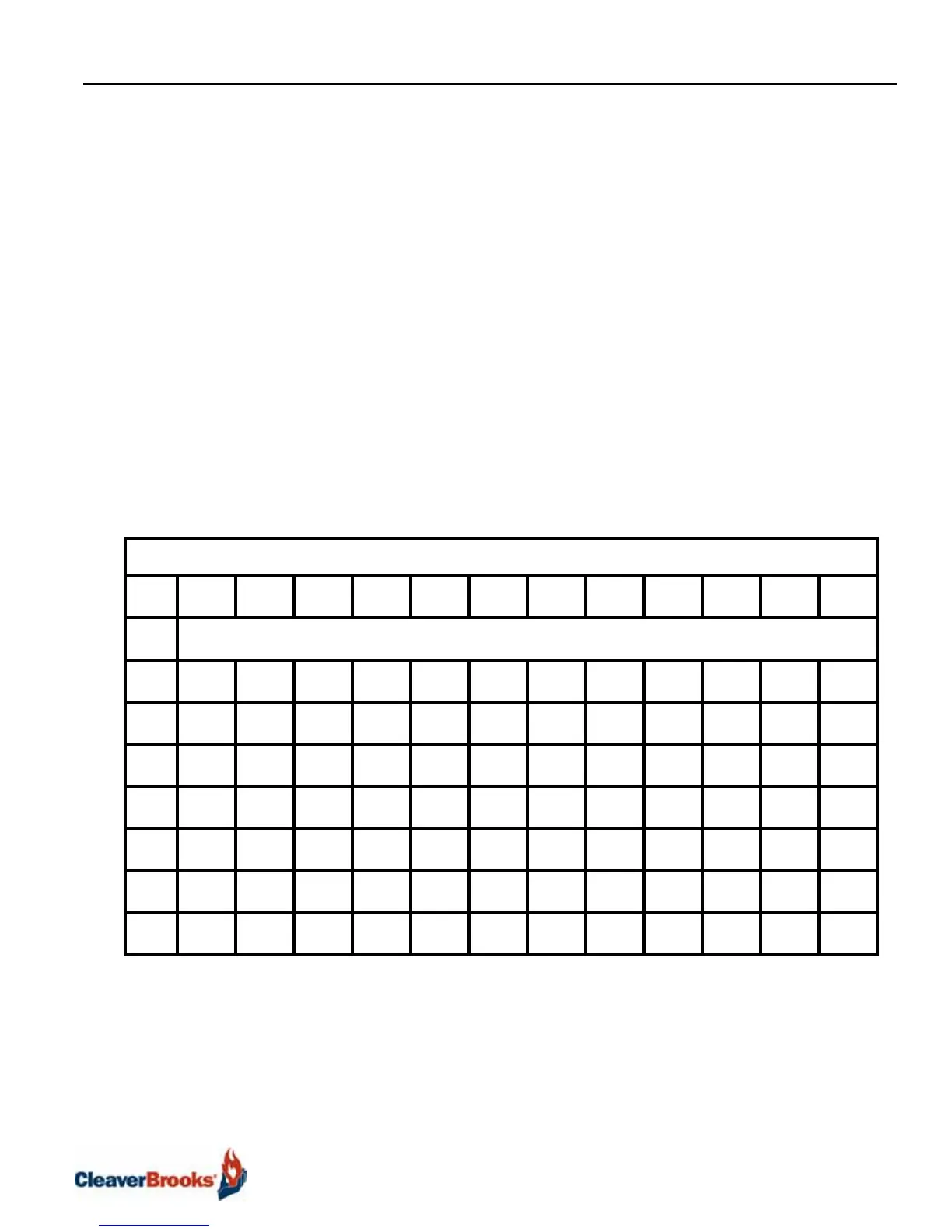

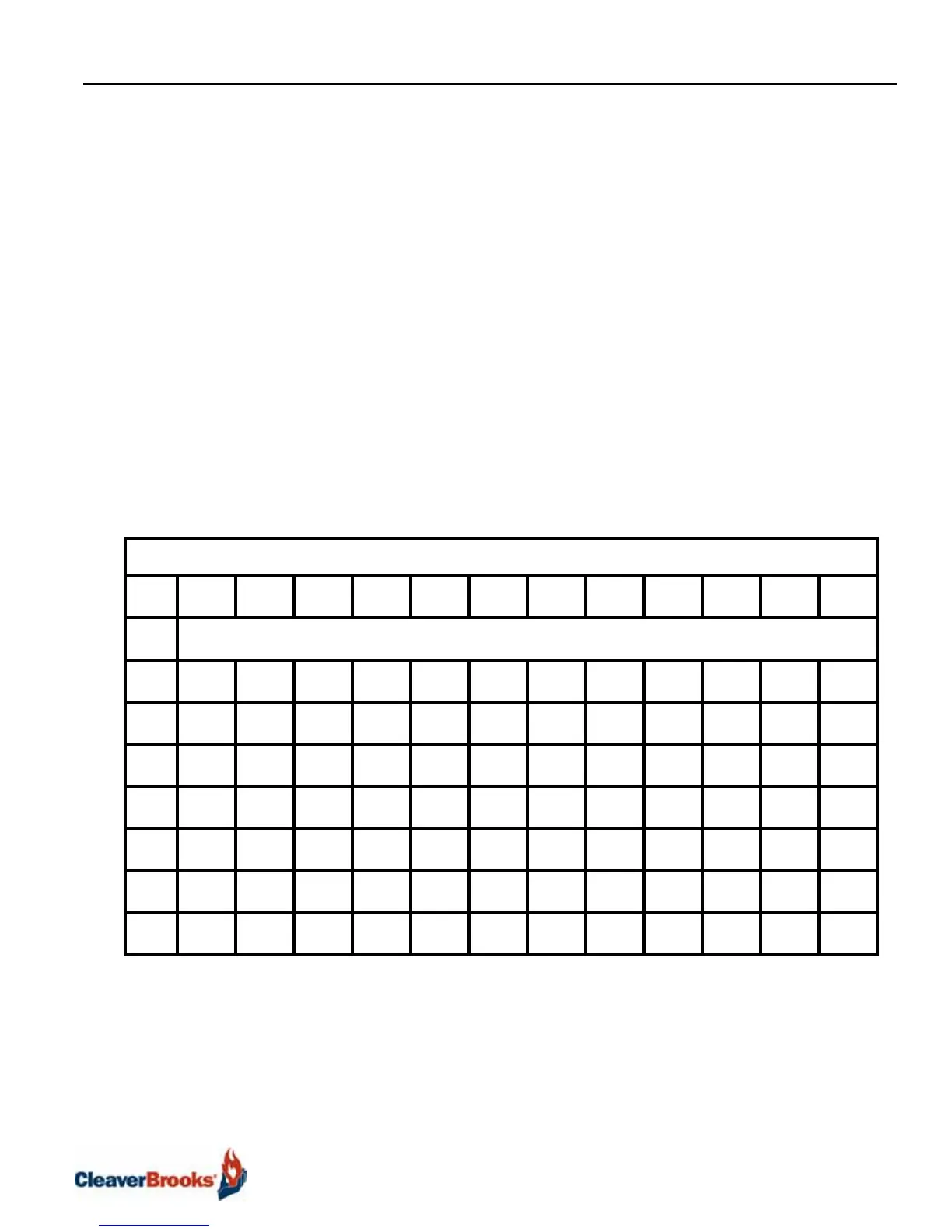

Table B5-12. CFC Flow Rates

System Temperature Drop

0

F

10 20 30 40 50 60 70 80 90 100 110 120

Boiler

Size

Flow Rate GPM

500 95 48 33 24 19 16 12 11 10.5 9 8 7

750 131 66 44 33 26 22 19 16 15 13 12 11

1000 176 88 59 44 35 29 25 22 20 18 16 15

1500 260 130 87 65 52 43 37 33 29 26 24 23

1800 351 176 117 88 70 59 50 44 39 35 32 30

2500 470 235 157 118 95 79 67 59 52 48 43 39

3300 620 310 207 155 124 103 89 78 69 62 56 52

Flow rate as a function of Delta T at 94% efficiency and maximum firing capacity

Loading...

Loading...