Model CFC ClearFire Commercial Boilers

27 Rev. 05-2012

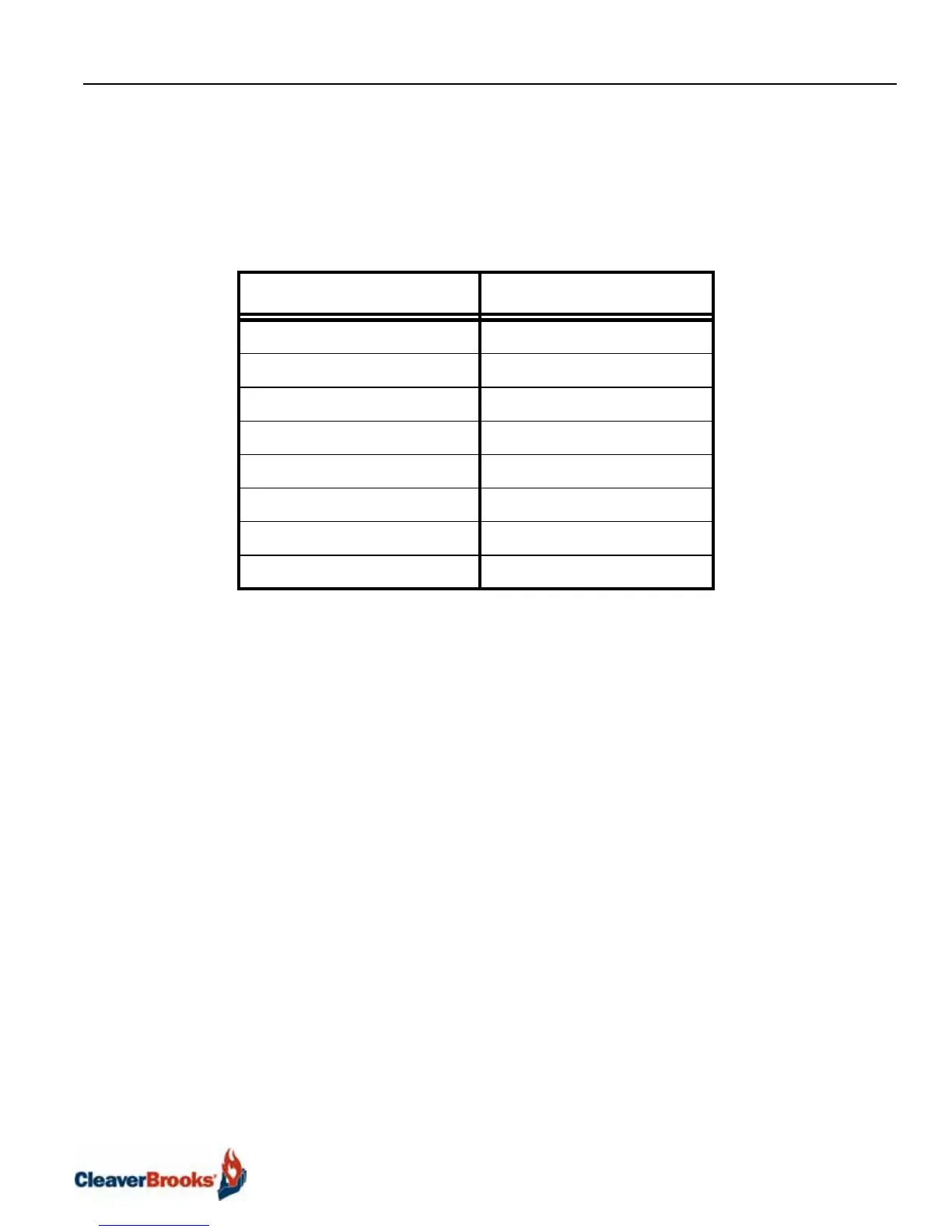

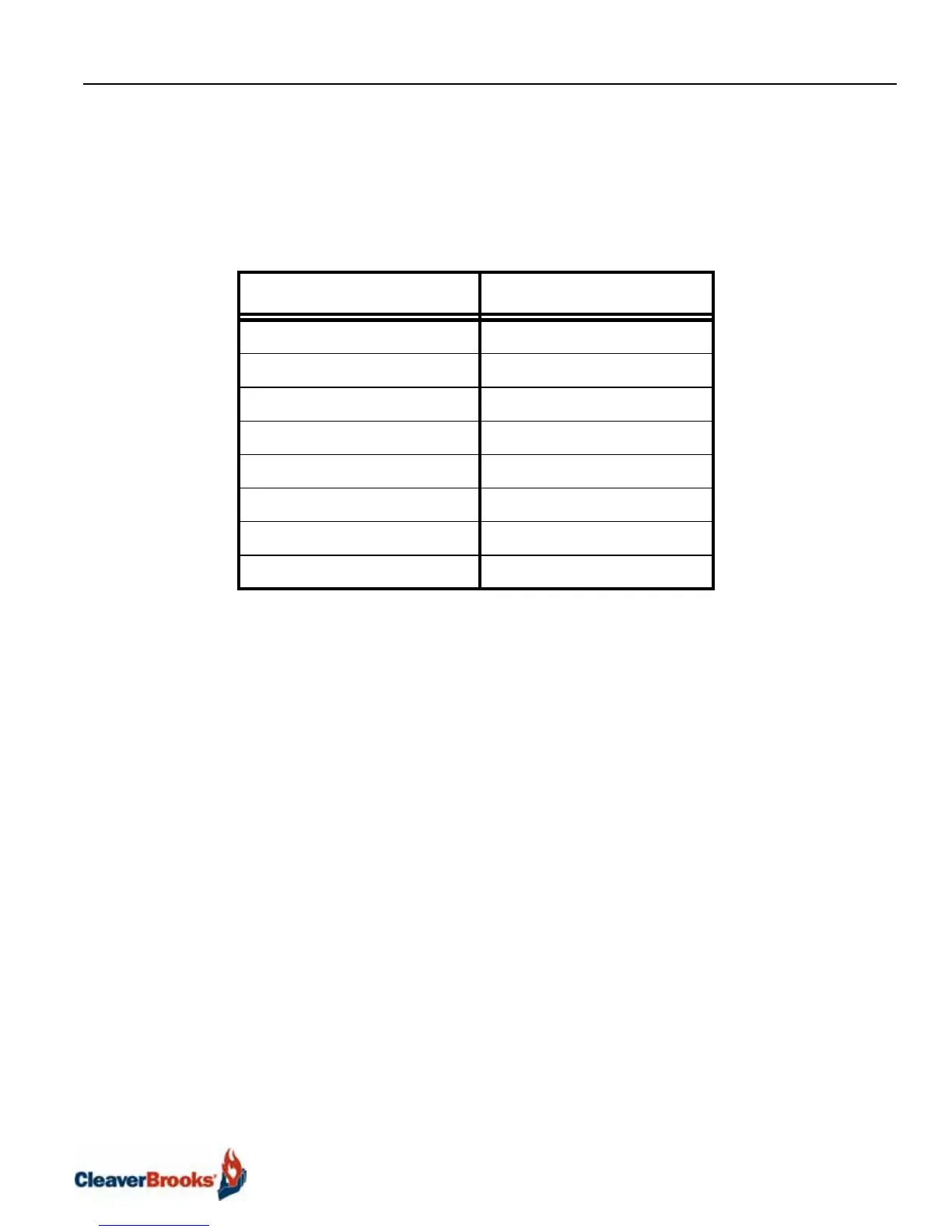

Water Treatment Even though hot water systems are "closed", some amount of make-up water (up to

10%) will be introduced. This more often than not happens from seal leaks of

pumps, or other minimal leaks from valves etc., that go unnoticed. Therefore,

proper water chemistry of a hot water boiler is necessary for good operation and

longevity, particularly to ensure that free oxygen is removed to prevent waterside

corrosion (see Table B5-17).

Table B5-17. Model CFC Water Chemistry Requirements in accordance with ABMA

Glycol The Model CFC boiler may be operated with a solution of glycol and water. Where

glycols are added, the system must first be cleaned and flushed. Correct glycol

selection and regular monitoring of the in-use concentration and its stability is

essential to ensure adequate, long-term freeze protection, as well as protection

from the effects of glycol-derived corrosion resulting from glycol degradation.

Typically, ethylene glycol is used for freeze protection, but other alternatives exist,

such as propylene glycol. Glycol reduces the water-side heat capacity (lower

specific heat than 100% water) and can reduce the effective heat transfer to the

system. Because of this, design flow rates and pump selections should be sized

with this in mind.

Generally, corrosion inhibitors are added to glycol systems. However, all glycols

tend to oxidize over time in the presence of oxygen, and when heated, form

aldehydes, acids, and other oxidation products. Whenever inadequate levels of

water treatment buffers and corrosion inhibitors are used, the resulting water glycol

mixture pH may be reduced to below 7.0 (frequently reaching 5) and acid corrosion

results. Thus, when pH levels drop below 7.0 due to glycol degradation the only

alternative is to drain, flush, repassivate, and refill with a new inhibited glycol

solution.

The following recommendations should be adhered to in applying ClearFire model

CFC boilers to hydronic systems using glycol:

1) Maximum allowable antifreeze proportion (volume %):

50% antifreeze (glycol)

50% water

Parameter Limit

Glycol 50%

pH 8.3 - 9.5

Nitrates 50 mg/liter

Sulphates 50 mg/liter

Chloride 30 mg/liter

Oxygen 0.1 mg/liter

Specific Conductivity

3500 mmho/cm

Total Hardness <10 ppm

Loading...

Loading...