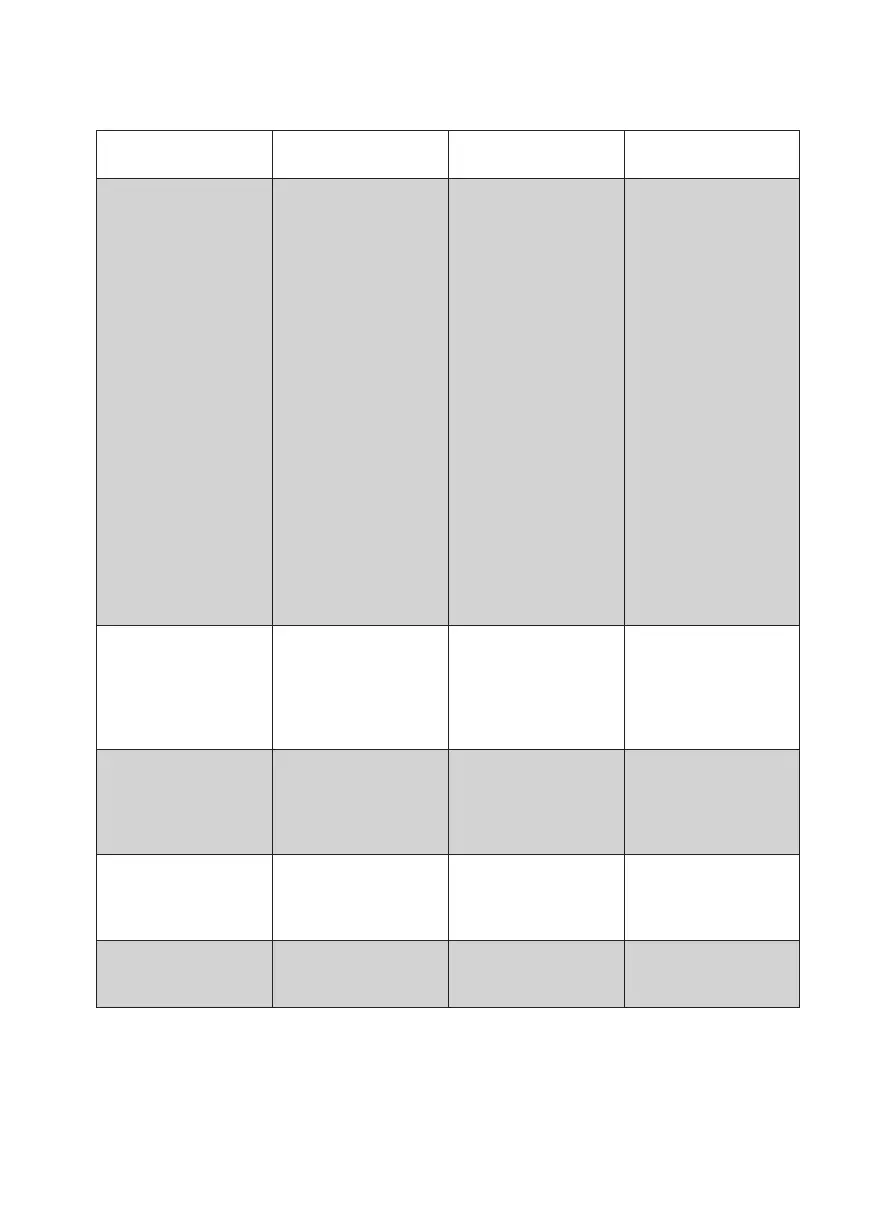

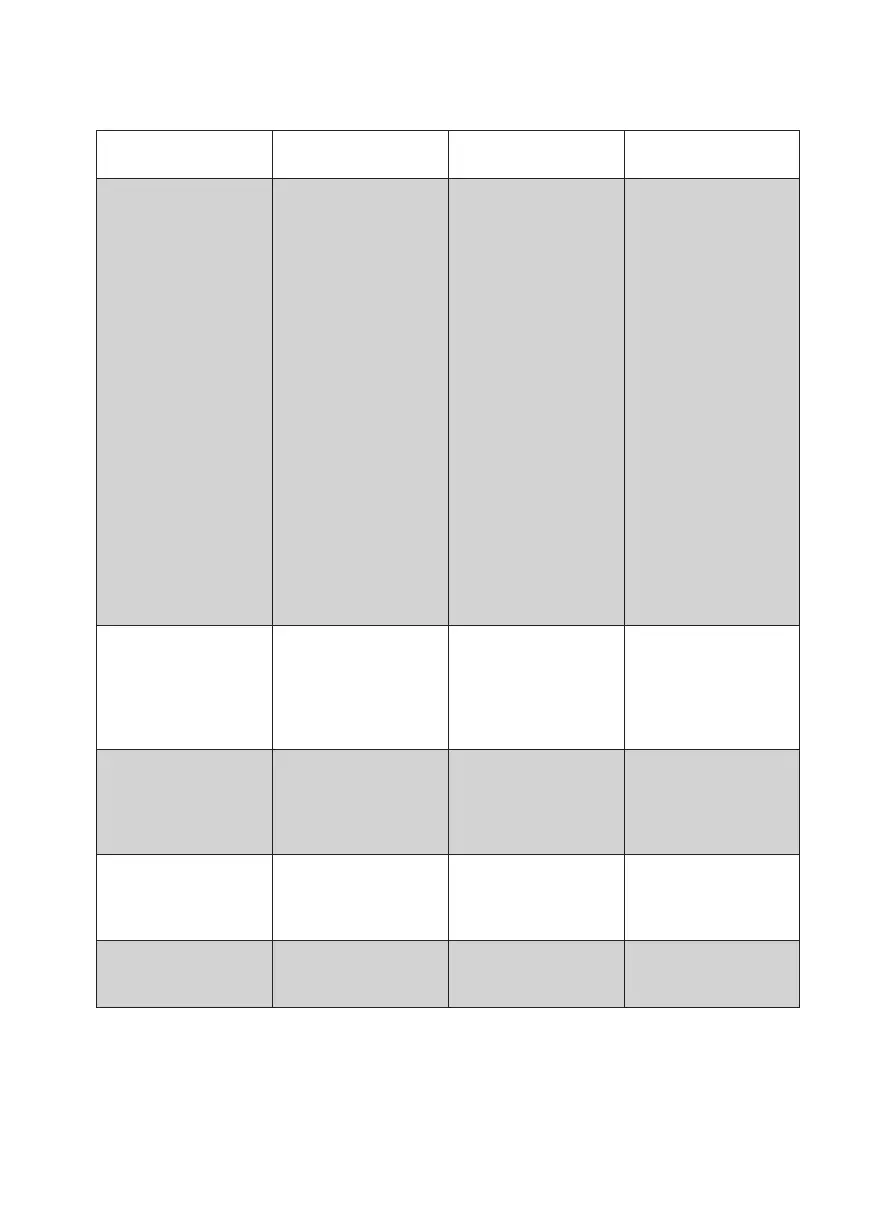

83

Pump Inspection Visual check for func-

tion and tightness

approx. 6 months

Maintenance Rehearsal:

Before, during or after

the test run, check:

¾ The electrical

protection of the

system in accor-

dance with VDE

regulations

¾ Preprint of the

MAG (if available)

¾ Tightness of the

pump‘s sliding ring

seal

¾ Function of the

setback preventer

¾ Pump and ow

noise

¾ Tightness of the

system and ttings

¾ Cleanliness of the

plant

¾ Corrosion of plant

parts

approx. 1year

Drinking water

re-feeding

Inspection Check of the safety

distance (water level

adjustment), the inlet

valve and the overow

when the inlet is fully

open

approx. 1year

Level indicator Inspection Comparison of the

level in the storage

with the level indicator

(switching rainwater /

drinking water).

approx. 1year

Pipelines Inspection Check all visible cables

for condition, tightness,

fastening and external

corrosion

approx. 1year

Backlog closures

(if available)

Inspection Actuating the operating

lock, if necessary, emer-

gency closure

approx. 1 month

Loading...

Loading...