Parameter

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

12 Digitax ST Advanced User Guide

www.controltechniques.com Issue Number: 1

2.8 Alarm and trip display

An alarm can flash alternately with the data displayed on the 2nd row

when one of the following conditions occur. If action is not taken to

eliminate the alarm, except "Auto tunE", "Lt" and "PLC", the drive may

eventually trip. Alarms flash once every 640ms except "PLC" which

flashes once every 10s. Alarms are not displayed when a parameter is

being edited.

When a trip occurs the drive switches to status mode and "trip" is shown

on the 1st row and the trip string flashes on the 2nd row. The read only

parameters listed below are frozen with any trip except UV trip until the

trip is cleared. For a list of the possible trip strings see Pr 10.20.

Pressing any of the parameter keys changes the mode to the parameter

view mode. If the trip is HF01 to HF16 then no key action is recognized.

2.9 Keypad control mode (SM-Keypad

Plus only)

The drive can be controlled from the keypad if Pr 1.14 is set to 4. The

Stop and Run keys automatically become active (the Reverse key may

be optionally enabled with Pr 6.13). The speed reference is defined by

Pr 1.17. This is a read only parameter that can only be adjusted in status

mode by pressing the Up or Down keys. If keypad control mode is

selected, then pressing the Up or Down keys in status mode will cause

the drive to automatically display the keypad reference and adjust it in

the relevant direction. This can be done whether the drive is disabled or

running. If the Up or Down keys are held the rate of change of keypad

reference increases with time. The units used for to display the keypad

reference is rpm.

2.10 Drive reset

A drive reset is required to: reset the drive from a trip (except some

“HFxx” trips which cannot be reset); and other functions as defined in

section 3 Parameter x.00 on page 13. A reset can be performed in four

ways:

1. Stop key: If the drive has been set up such that the stop key is not

operative then the key has a drive reset function only. When the stop

function of the stop key is enabled, a reset is initiated while the drive

is running by holding the Run key and then pressing the Stop key.

When the drive is not running the Stop key will always reset the

drive.

2. The drive resets after a 0 to 1 transition of the Drive Reset parameter

(Pr 10.33). A digital input can be programmed to change this

parameter.

3. Serial comms, fieldbus or applications Solutions Module: Drive reset

is triggered by a value of 100 being written to the User trip parameter

(Pr 10.38).

4. Auto-reset: Pr 10.34 can be used to provide an auto-reset function.

If the drive trips EEF (internal EEPROM error) then it is not possible to

reset the drive using the normal reset methods described above. 1233 or

1244 must be entered into Pr x.00 before the drive can be reset. Default

parameters are loaded after an EEF trip, and so the parameters should

be reprogrammed as required and saved in EEPROM.

If the drive is reset after a trip from any source other than the Stop key,

the drive restarts immediately, if:

1. A non-latching sequencer is used with the enable active and one of

run forward, run reverse or run active

2. A latching sequencer is used if the enable and “not stop” are active

and one of run forward, run reverse or run is active.

If the drive is reset with the Stop key the drive does not restart until a not

active to active edge occurs on run forward, run reverse or run.

2.11 Second motor parameters

An alternative set of motor parameters are held in menu 21 which can be

selected by Pr 11.45. When the alternative parameter set is being used

by the drive the decimal point after the right hand digit in the 1st row is

on.

2.12 Special display functions

The following special display functions are used.

1. If the second motor map is being used the decimal point second

from the right of the first row is on.

2. When parameters are saved to a SMARTCARD the right-most

decimal point on the first row flashes for 2 seconds.

During power up one or more of the following actions may be required.

Each action may take several seconds, and so special display strings

are shown.

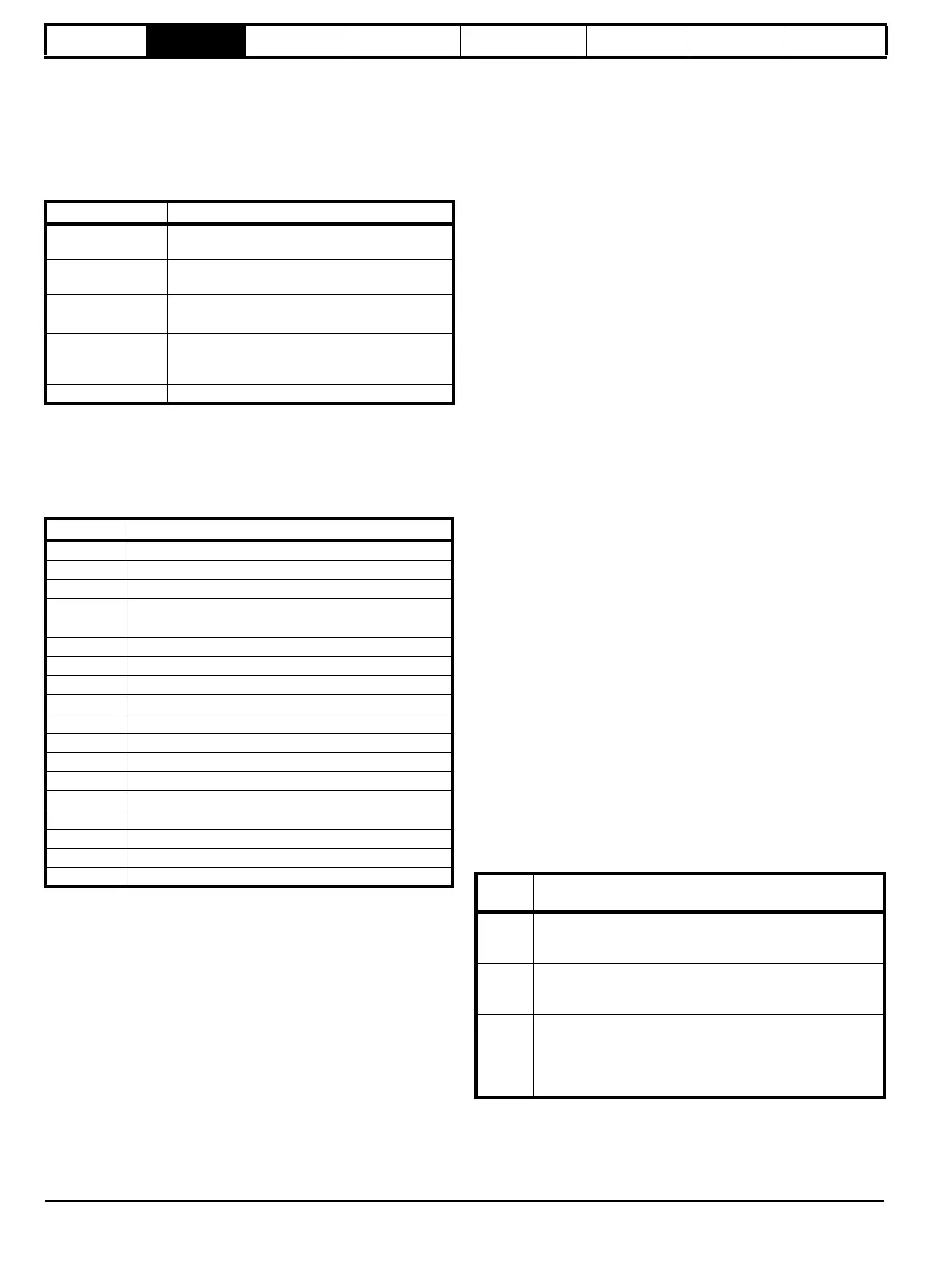

Alarm string Alarm condition

br.rS

Braking resistor (Pr 10.39 > 75.0% and the

braking IGBT is active)

OVLd

Motor overload (Pr 4.20 > 75% and the drive

output current > Pr 5.07)

hot Heatsink or control board alarms are active

Auto tunE Auto tune in progress

Lt

Indicates that a limit switch is active and that it is

causing the motor to be stopped (i.e. forward

limit switch with forward reference etc.)

PLC On-board PLC program is running

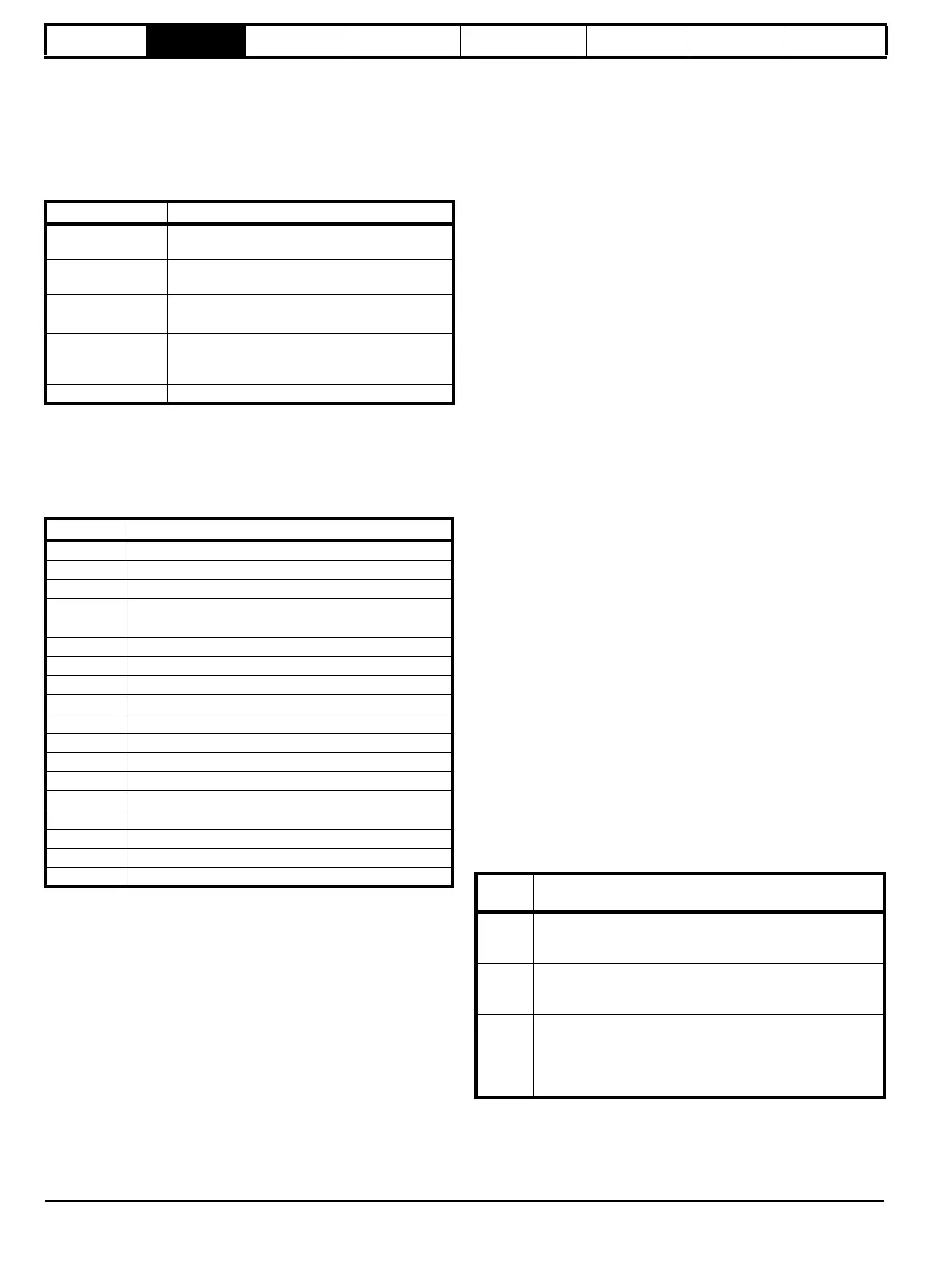

Parameter Description

1.01 Speed reference

1.02 Speed reference

1.03 Pre-ramp reference

2.01 Post-ramp reference

3.01 Final speed reference

3.02 Speed feedback

3.03 Speed error

3.04 Speed controller output

4.01 Current magnitude

4.02 Active current

4.17 Magnetising current

5.01 Output frequency

5.02 Output voltage

5.03 Power

5.05 DC bus voltage

7.01 Analog input 1

7.02 Analog input 2

7.03 Analog input 3

Display

string

Action

boot

If a SMARTCARD is present with Pr 11.42 set to boot the

parameters from the card must be transferred to the drive

EEPROM.

card

If the drive is in auto or boot mode (Pr 11.42 set to 3 or 4) the

drive ensures that the data on the card is consistent with the

drive by writing to the card.

loading

It may be necessary for a Solutions Module to transfer

parameter information from the drive. This is only carried out

if the parameter information held by the Solutions Module is

for a different drive software version. The drive allows up to 5

seconds for this process.

Loading...

Loading...