Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

Menu 10

Digitax ST Advanced User Guide 127

Issue Number: 1 www.controltechniques.com

C.rtg SMARTCARD trip: The voltage and/or current rating of the source and destination drives are different

186

Drive rating dependent parameters (parameters with the RA coding) are likely to have different values and ranges with drives of

different voltage and current ratings. Parameters with this attribute will not be transferred to the destination drive by SMARTCARDs

when the rating of the destination drive is different from the source drive and the file is a parameter file. Drive rating dependent

parameters will be transferred if only the current rating is different and the file is a differences from default type file.

Press the red reset button

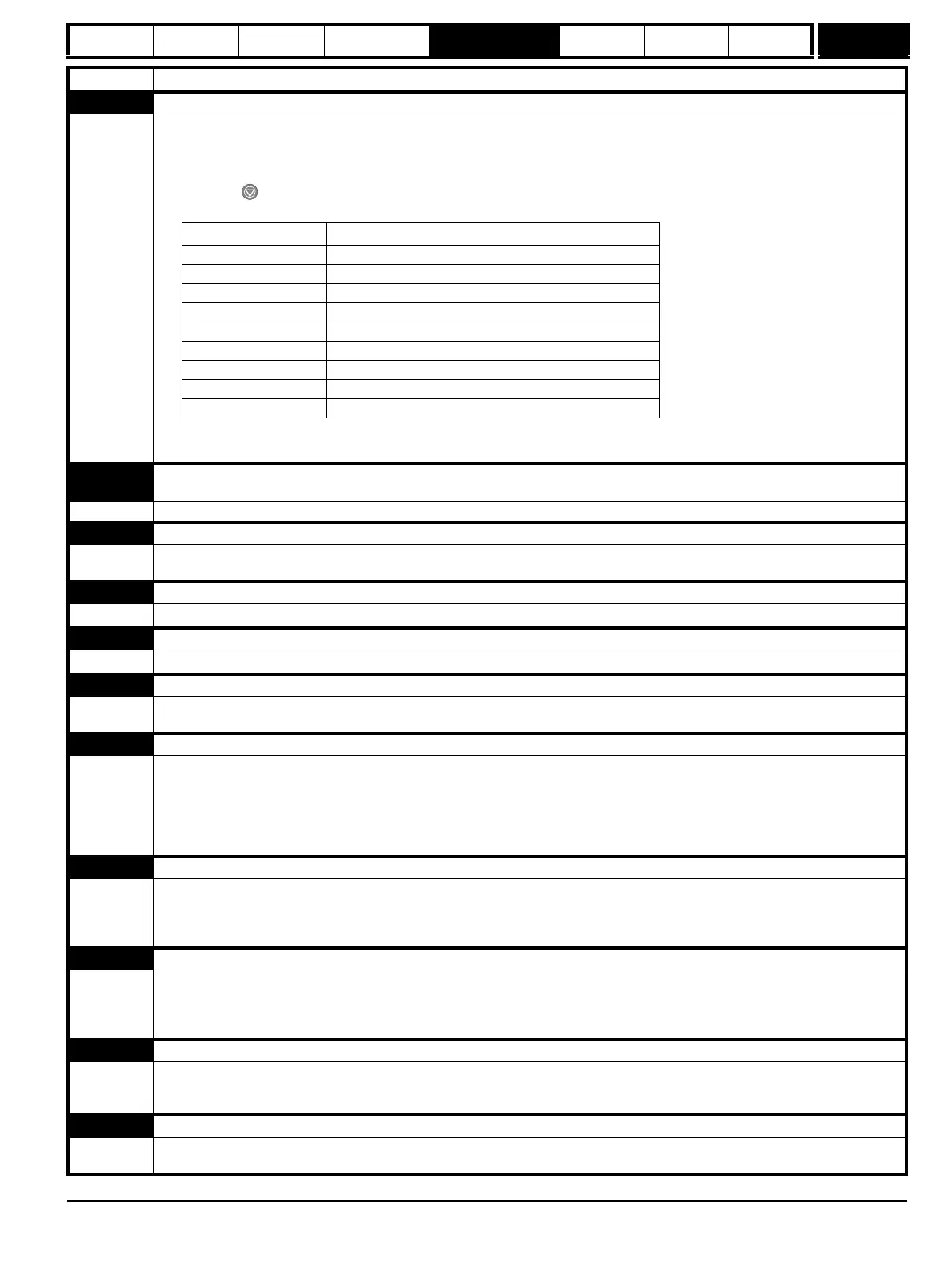

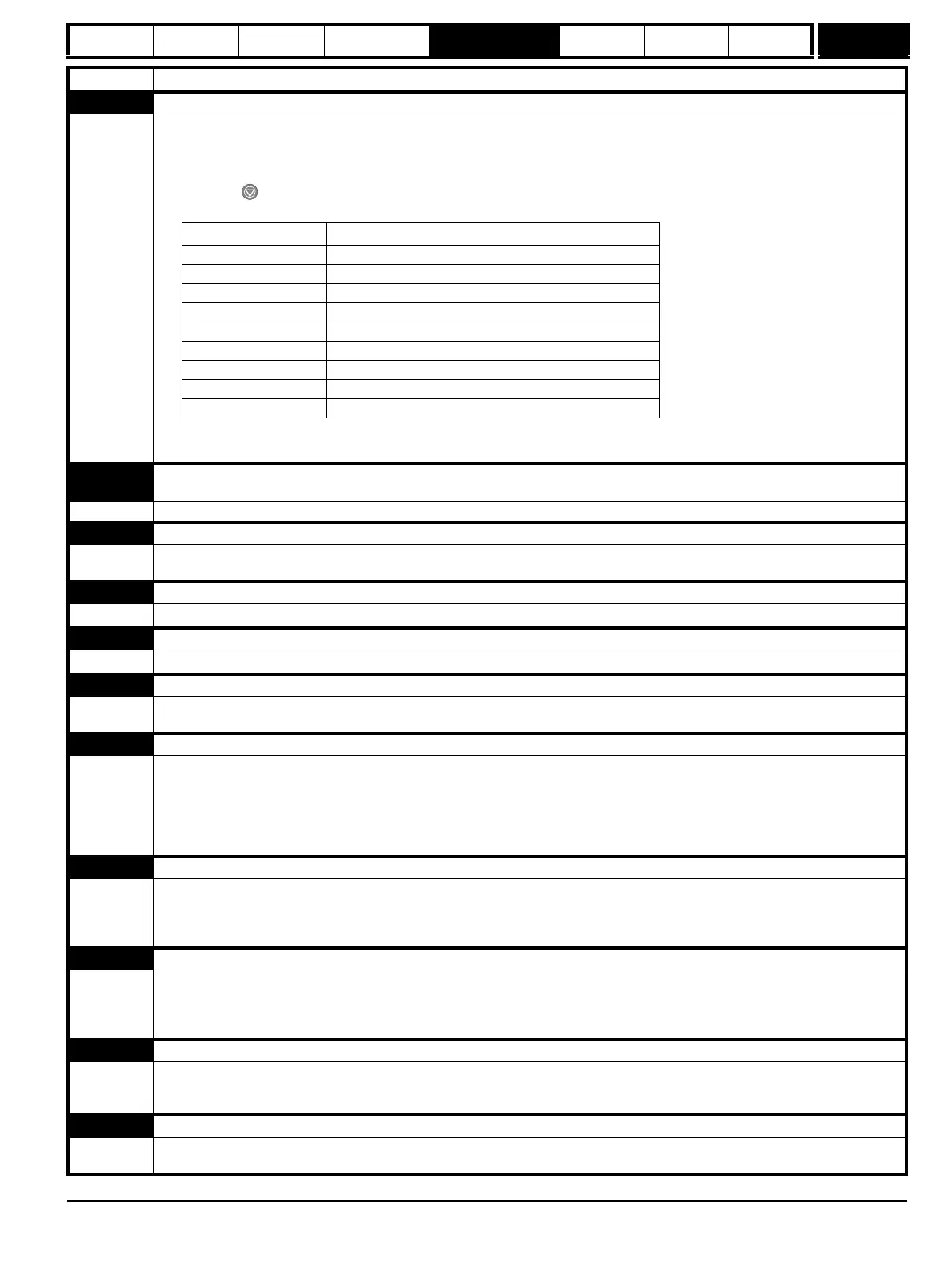

Drive rating parameters are:

The above parameters will be set to their default values.

C.SLX

An error has occurred when attempting to transfer a user program from a Solutions Module to a SMARTCARD and vice

versa

172,173,174 See Pr 11.37 for more details

C.TyP SMARTCARD trip: SMARTCARD parameter set not compatible with drive

187

Press the reset button

Ensure destination drive type is the same as the source parameter file drive type

dESt Two or more parameters are writing to the same destination parameter

199 Set Pr xx.00 = 12001 check all visible parameters in the menus for duplication

EEF EEPROM data corrupted - Serial comms will timeout with remote keypad on the drive RS485 comms port.

31 This trip can only be cleared by loading default parameters and saving parameters

EnC1 Drive encoder trip: Encoder power supply overload

189

Check encoder power supply wiring and encoder current requirement

Maximum current = 200mA @ 15V, or 300mA @ 8V and 5V

EnC2 Drive encoder trip: Wire break (Drive encoder terminals 1 & 2, 3 & 4, 5 & 6)

190

Check cable continuity

Check wiring of feedback signals is correct

Check encoder power is set correctly

Check that the encoder cable is connected to the right encoder port on the drive (not to the buffered encoder output port)

Replace feedback device

If wire break detection on the main drive encoder input is not required, set Pr 3.40 = 0 to disable the EnC2 trip

EnC3 Drive encoder trip: Phase offset incorrect While running

191

Check the encoder signal for noise

Check encoder shielding

Check the integrity of the encoder mechanical mounting

Repeat the offset measurement test

EnC4 Drive encoder trip: Feedback device comms failure

192

Ensure encoder power supply is correct

Ensure baud rate is correct

Check encoder wiring

Replace feedback device

EnC5 Drive encoder trip: Checksum or CRC error

193

Check the encoder signal for noise

Check the encoder cable shielding

With EnDat encoders, check the comms resolution and/or carry out the auto-configuration Pr 3.41

EnC6

Drive encoder trip: Encoder has indicated an error

194

Replace feedback device

With SSI encoders, check the wiring and encoder supply setting

Trip Diagnosis

Parameter Function

2.08 Standard ramp voltage

4.05/6/7, 21.27/8/9 Current limits

4.24 User current maximum scaling

5.07, 21.07 Motor rated current

5.09, 21.09 Motor rated voltage

5.17, 21.12 Stator resistance

5.18 Switching frequency

5.24, 21.14 Transient inductance

6.48 Line power supply loss ride through detection level

Loading...

Loading...