Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

Menu 5

Digitax ST Advanced User Guide 87

Issue Number: 1 www.controltechniques.com

Pr 5.37 shows the actual switching frequency used by the inverter. The maximum switching frequency is set with parameter Pr 5.18, but this may be

reduced by the drive if automatic switching frequency changes are allowed (Pr 5.35=1). Pr 5.37 also indicates if the sample time for the current

controllers have been reduced to allow for SINCOS encoders with lines per revolution that are not a power of two.

By applying short current pulses to the motor and using the resulting movement the drive can calculate the phasing angle (Pr 3.25 or Pr 21.20). These

begin at as short low level pulses, which are increased in magnitude and length until the required electrical movement define by Pr 5.38 is achieved.

The actual movement may be larger because motor cogging may cause additional unwanted movement. The required movement should only be

reduced if this is necessary as the results become less accurate with less movement. Care should be taken to ensure that the minimum movement is

large enough so that the change of position given by the feedback device can be registered by the drive. For example a 4096 line incremental device

on a 6 pole motor will give a change of position count of 75 for a 5°electrical movement. It is suggested that this test should not be used with a change

of position count of less than 50. Although Pr 5.38 can be reduced to zero the lowest value used by the drive is 1.0 degrees.

The necessary movement can be produced with a lower torque level if the test pulses are extended. If the pulses of torque are smaller then the

acceleration is less, and so the noise and vibration produced by the test are less. The pulse length can be modified with Pr 5.39 (1 = pulse lengths x

2, 2 = x 3, and 3 = x 4). Longer pulses should only be used if noise and vibration are a problem and the motor has low friction and low cogging torque.

As the torque level is reduced the measurement is likely to be affected by cogging and the results may not be accurate.

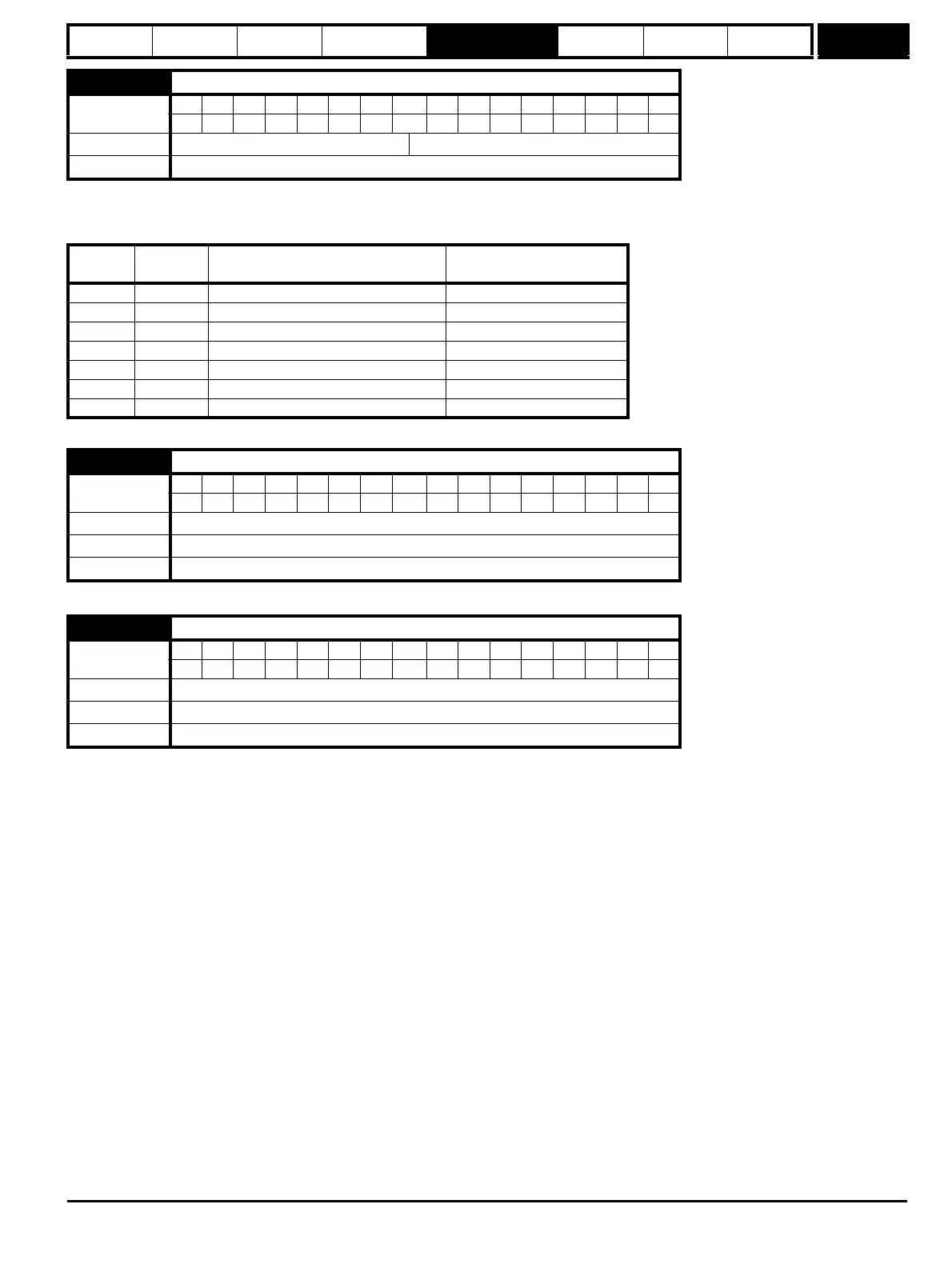

5.37 Actual switching frequency

Coding

BitSP FI DETEVMDPNDRANCNVPTUSRWBUPS

11111

Range 0 to 7

Update rate

Background write

Value String Switching frequency (kHz)

Current controller Sample

time (us)

03 3 167

14 4 125

26 6 83

38 8 125

412 12 83

66 rEd 6 167

7 12 rEd 12 167

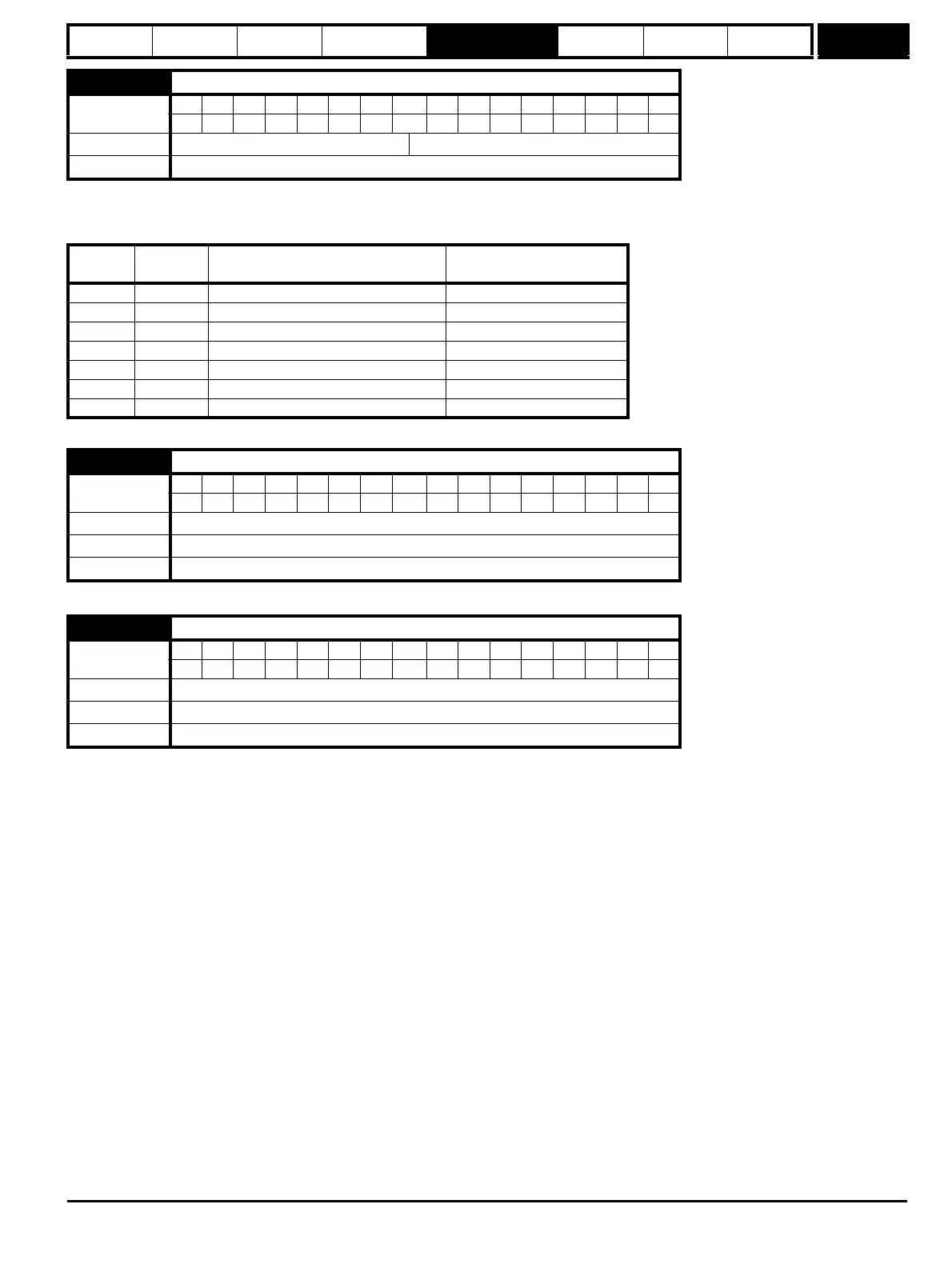

5.38 Minimal movement phasing test angle

Coding

BitSP FI DETEVMDPNDRANCNVPTUSRWBUPS

1111

Range 0 to 25.5 degrees

Default 5.0 degrees

Update rate

Background read

5.39 Minimal movement phasing test pulse length

Coding

BitSP FI DETEVMDPNDRANCNVPTUSRWBUPS

111

Range 0 to 3

Default 0

Update rate

Background read

Loading...

Loading...