being unloaded will minimize heat loss from the discharge

line for the best liquid transfer rate.

Unloading stationary tanks with a compressor is quite

practical. Delivery trucks and other large containers can

be filled rapidly if the vapor system of the tank to be

filled will permit fast vapor withdrawal, and if the liquid

piping system is large enough. Many older trucks (and

some new ones) are not originally equipped with vapor

excess flow valves large enough to do a good job and

these should be replaced by a suitable size valve. The

liquid discharge should be connected to the tank truck

pump inlet line rather than the often oversized filler valve

connection in the tank head.

It is of extreme importance to prevent the entry of

liquid into the compressor. The inlet of the compressor

should be protected from liquid entry by a liquid trap

(see section 2.4). It is of equal importance to protect the

discharge of the compressor from liquid. This may be

done by installing a check valve on the discharge and

designing the piping so liquid cannot gravity-drain back

into the compressor. Make sure to install a check valve

on vapor lines discharging to the liquid space of the tank.

All piping must be in accordance with the laws and codes

governing the service. In the United States, the following

codes apply:

For LP-Gas — The National Fire Protection Association

Pamphlet No. 58, Standard for the Storage and Handling

of Liquefied Petroleum Gases.

For Ammonia — The American National Standards

Institute, Inc., K61.1-1999, Storage and Handling of

Anhydrous Ammonia.

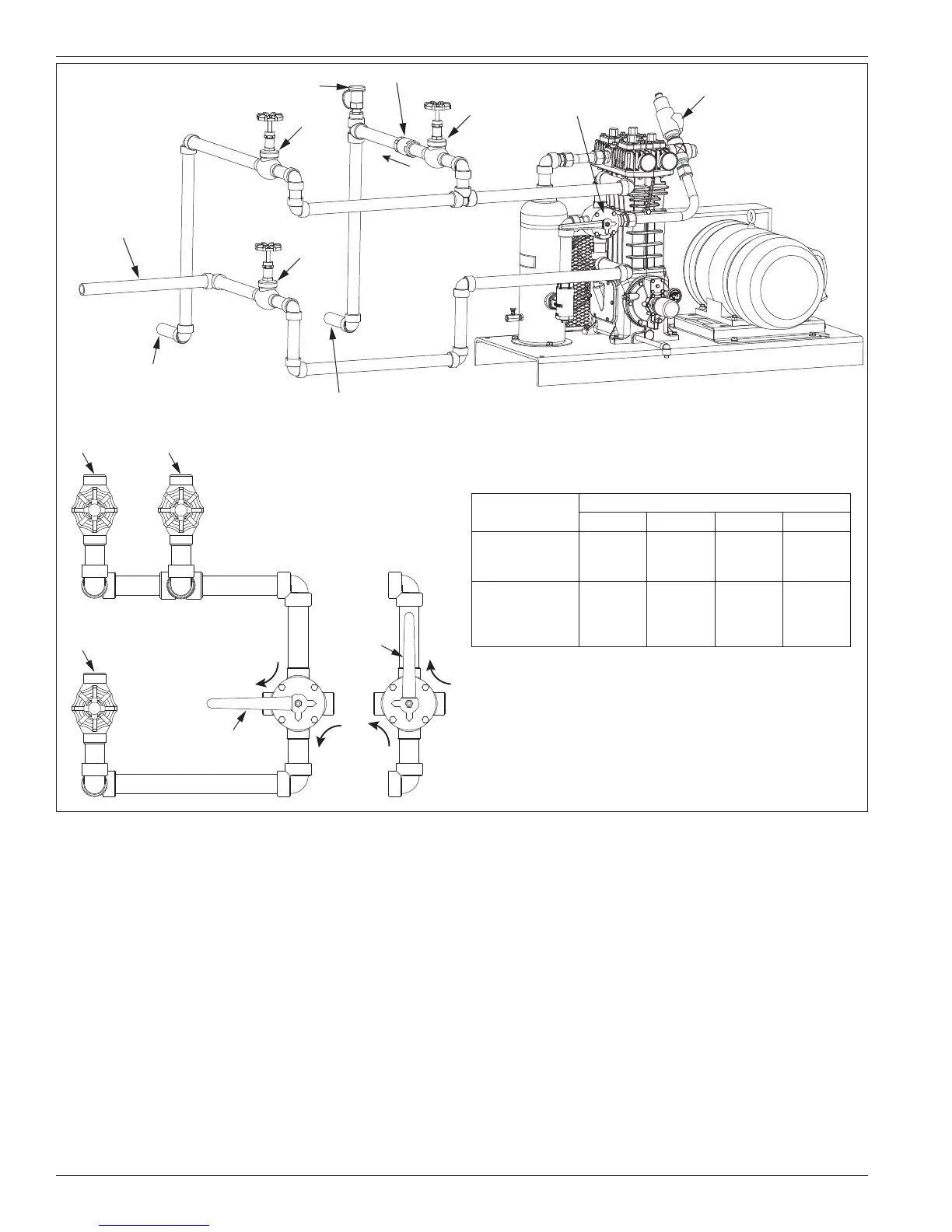

Back check valve

Hydrostatic releif valve

A

B

C

Vapor line rail car

(in-bound

bulk transfer)

Bury or insulate in

cold climate areas

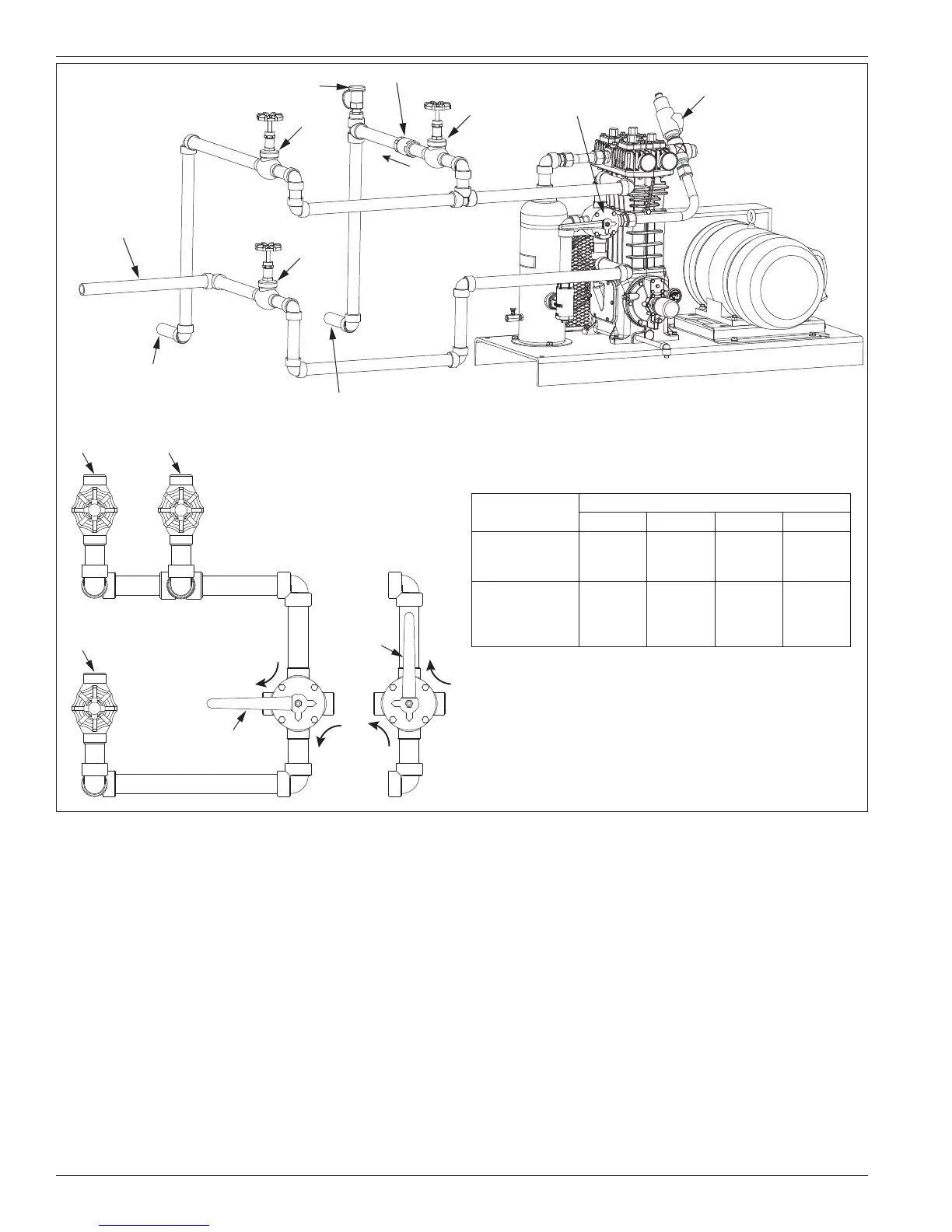

4-Way valve

Relief valve

Vapor line to gas

phase in storage

Vapor line to liquid

phase in storage

4-Way Valve

Position 1

B

4-Way Valve

Position 2

Service to

Perform

Valve Position

4-way A B C

1. Unload

tank car into

storage tank

Position

One

Open Open Close

2. Recover

vapors from

tank car into

storage tank

Position

Two

Close Open Open

4-way Valve Operation

Figure 2.3C: Three valve manifold piping system.

10

Loading...

Loading...