Disassembly

1. Unscrew the valve cap/nut and remove the O-ring

from the coverplate.

2. Remove the valve cover plate, O-ring and holddown

screw by removing each of the four bolts. NOTE:

Since the holddown screw has been secured with an

impact wrench at the factory, you will probably need

to wait to remove the holddown screw until after the

cover plate has been removed. At this point in time,

the holddown screw can be easily removed from the

cover plate. The holddown screw on model 691 and

891 is most easily removed with the special wrench

supplied with your compressor at time of purchasing.

3. After the cover plate and O-ring have been removed,

the valve spacer (model 491 only), valve cage, valve

assembly and valve gasket can be lifted out.

4. Inspect valves for breakage, corrosion, debris,

and scratches on the valve plate. In many cases,

valves may simply be cleaned and reinstalled. If the

valves show any damage, they should be repaired or

replaced. Replacement is usually preferable although

repair parts are available. If valve plates are replaced,

seats should also be lapped until they are perfectly

smooth. If more than .005 in. must be removed

to achieve a smooth surface, the valve should be

discarded. If plates are replaced without relapping the

seat, rapid wear and leakage may occur.

Assembly

1. Insert metal valve gasket into the suction and/or

discharge opening of the head. The metal valve gasket

should always be replaced when the valve is reinstalled.

2. Insert cleaned or new valve assembly. Make sure the

suction and discharge valves are in the proper suction

and discharge opening in the head.

3. Insert the valve cage and valve spacer (NOTE: spacer

applies to model 491 compressor only).

4. Replace the O-ring and valve cover plate. Torque

bolts to the value listed in Appendix B. CAUTION: Be

sure the holddown screw has been removed.

5. Insert the holddown screw and tighten to the value

listed in Appendix B to ensure the valve gasket is

properly seated. NOTE: Gaskets and O-rings are not

normally reusable.

6. Replace the O-ring (or gasket) and valve cap/nut and

tighten to the value listed in Appendix B. O-rings

sealing the valve cap should be replaced if they show

signs of wear or damage. Valve caps sealed by flat

metals gaskets should be reinstalled with new gaskets.

7. NOTE: The Model 491 Spec 3 suction valve has an

adjusting screw to set the liquid relief pressure. To set

the liquid relief pressure, the screw bottom must be

tightened to 1.8" from the top of the valve body.

8. Check bolts and valve holddown screws after first

week of operation. Re-torque if necessary. See

Appendix B for torque values.

5.2 Heads

A compressor head very seldom requires replacement

if the compressor is properly maintained. The primary

cause of damage to a head is corrosion and the entry

of solid debris or liquid into the compression chamber.

Improper storage can also result in corrosion damage to

the head (for proper storage instructions see chapter 6).

Many compressor repair operations require removal of the

head. While the compressor is disassembled, special care

should be taken to avoid damage or corrosion to the head. If

the compressor is to be left open for more than a few hours,

bare metal surfaces should be coated with rust preventative.

When reassembling the compressor, make sure the bolts

are retightened as shown in Appendix B.

5.3 Piston Rings and Piston Ring

Expanders

Piston ring life will vary considerably from application to

application. Ring life will improve dramatically at lower

speeds and temperatures.

1. To replace the piston rings, depressurize the

compressor and purge if necessary.

2. Remove the head to gain access to the compressor

cylinder.

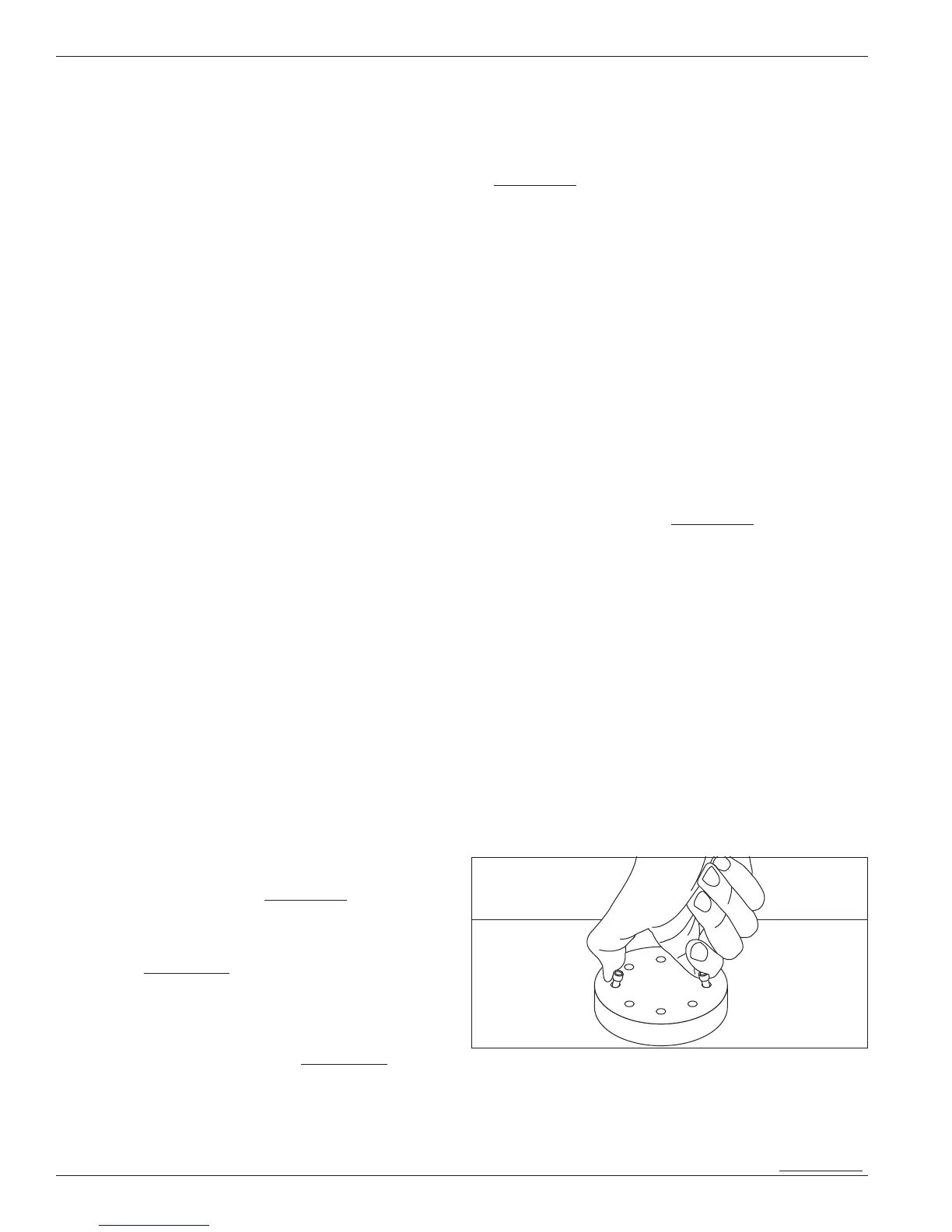

3. Loosen the piston head bolts. Remove the piston as

shown in figure 5.3A by pinching two loose bolts together.

Figure 5.3A: Piston removal

4. Piston rings and expanders may then be easily

removed and replaced. Corken recommends replacing

expanders whenever rings are replaced. To determine

if rings should be replaced, measure the radial

thickness and compare it to the chart in Appendix C.

20

Loading...

Loading...