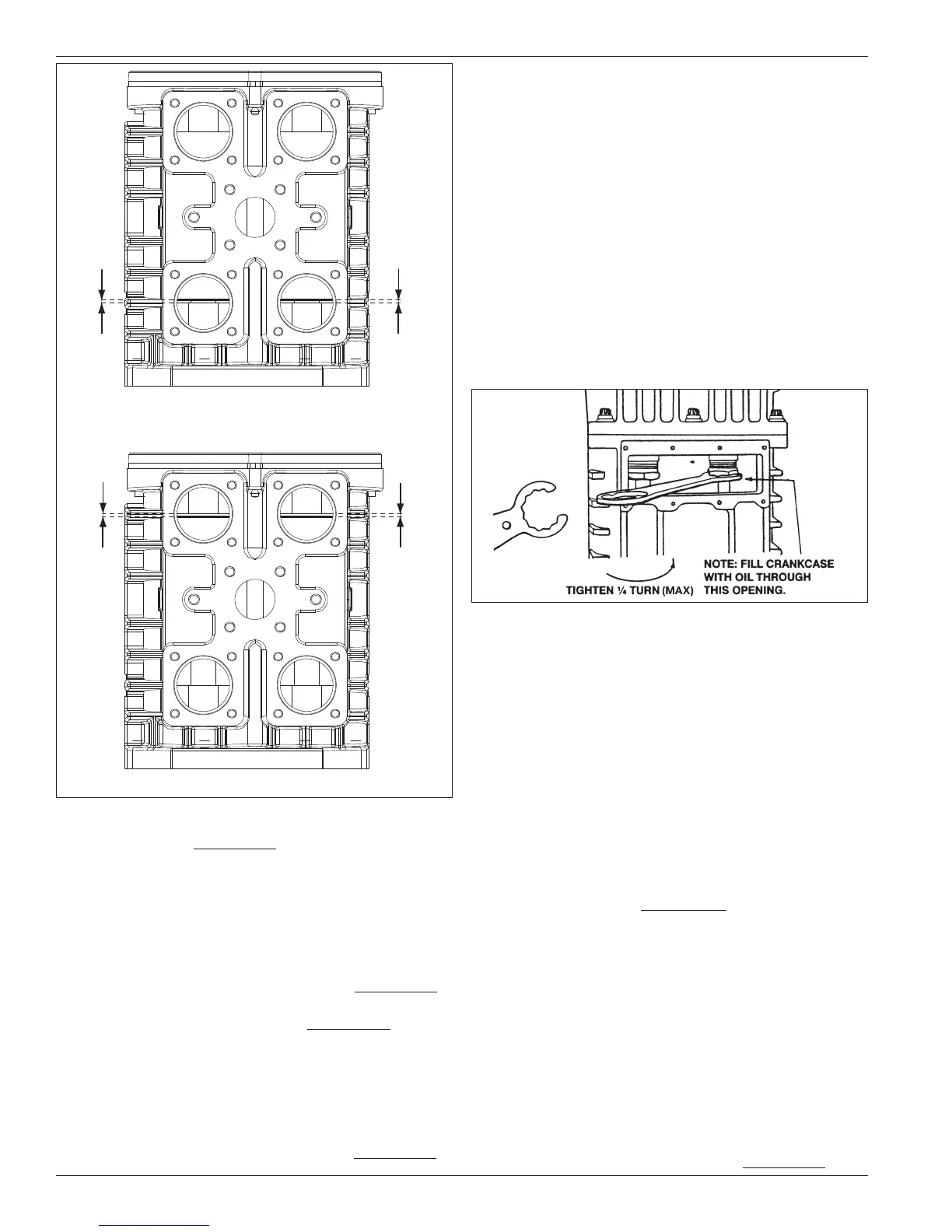

Piston top dead center

Piston

Piston

(

X

) (

X

)

Piston bottom dead center

Piston

Piston

(

Y

) (

Y

)

10. When the piston is properly shimmed, tighten the lock

nut as shown in Appendix B.

11. Replace the piston cap with the same thickness of

shims as before.

12. Reinstall the piston cap and cylinder head.

13. Now remove an upper valve and measure dimension

“X” at the top of the piston shown in Appendix E—

Piston Assembly Details. If this measurement does

not fall within the tolerances in Appendix E, remove

the cylinder head and piston cap and adjust the shims

as necessary. Repeat the steps and measure the “X”

dimension again.

14. When the piston cap is properly shimmed, tighten the

socket head bolts in an alternating sequence. Torque

socket head bolt to the values listed in Appendix B.

15. Replace the previously removed valves. Best results

will be obtained if new valve gaskets are used.

16. Follow standard startup procedures.

5.5 Piston Rod Packing

Adjustment

Piston rod packing should be adjusted or replaced

whenever leakage becomes noticeable. Typically, it is a

good idea to replace piston rod packing and piston rings

at the same time. For instructions on replacing the piston

rod packing, see section 5.6.

NOTE: Packing that cannot be adjusted should be

replaced.

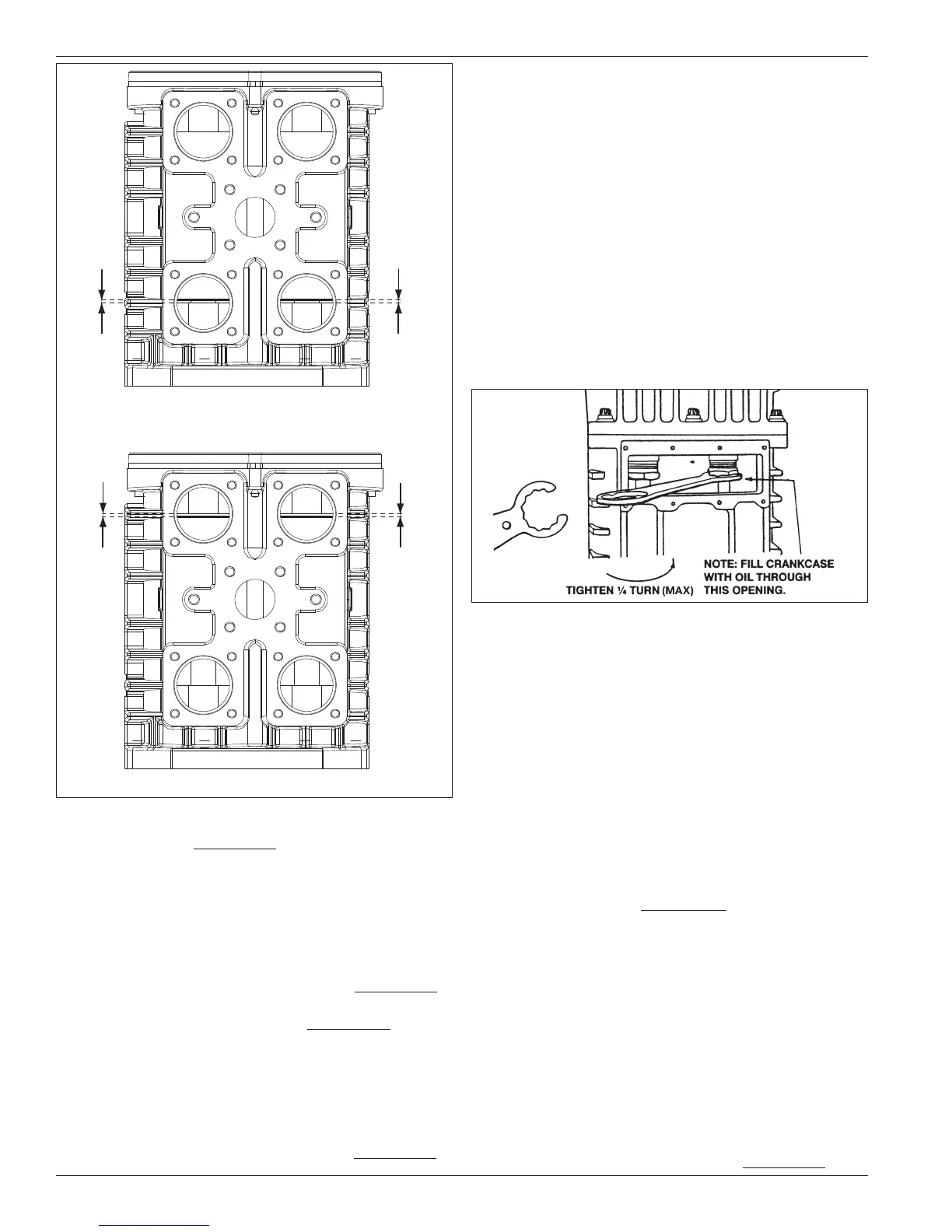

Figure 5.5A: Packing adjusting nuts.

5.6 Cylinder and Packing

Replacement

Cylinders very seldom require replacement if the

compressor is properly maintained. The primary

cause of damage to cylinders is corrosion and the

entry of solid debris or liquid into the compression

chamber. Improper storage can also result in corrosion

damage to cylinder (for proper storage instructions

see chapter 6).

If the cylinder does become damaged or corroded, use

a hone to smooth the cylinder bore and then polish it

to the value shown in Appendix B. If more than .005

in. must be removed to smooth the bore, replace the

cylinder. Cylinder liners and oversized rings are not

available. OVERBORING THE CYLINDER WILL RESULT

IN GREATLY REDUCED RING LIFE.

Many compressor repair operations require removal of

the cylinder. While the compressor is disassembled,

special care should be taken to avoid damage or

corrosion to the cylinder. If the compressor is to be left

open for more than a few hours, bare metal surfaces

should be coated with rust preventative.

When reassembling the compressor, make sure the bolts

are retightened to the valves shown in Appendix B.

22

Loading...

Loading...