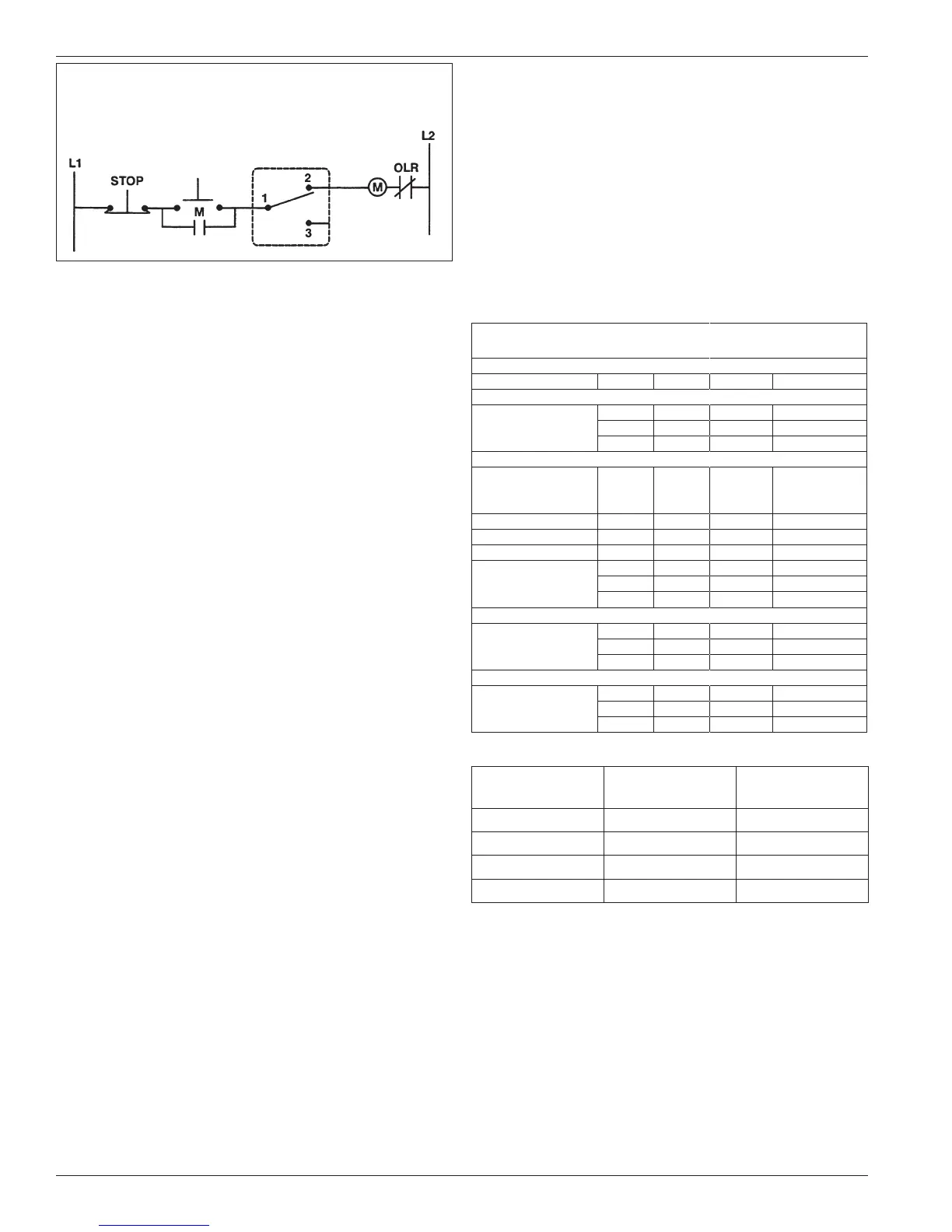

Typical Float Switch Wiring Diagram

1 = Common, black

2 = Normally closed, blue

3 = Normally open, red

Figure 2.4B: Typical float switch wiring diagram.

NOTE: The level switch MUST be removed from

the trap before grounding any welding devices to

the trap or associated piping! Failure to do so will

damage the switch contacts.

If your compressor is equipped with a liquid trap

of other than Corken manufacture, make sure it is

of adequate size to thoroughly remove any liquid

present in the suction stream.

2.5 Driver Installation / Flywheels

Corken vertical compressors may be driven by either

electric motors or combustion engines (gasoline, diesel,

natural gas, etc.). Corken compressors are usually V-belt

driven but they are also suitable for direct drive applications

as well. Direct drive applications require an extended

crankshaft to allow the attachment of a rigid metal coupling.

Note: Flexible couplings are not suitable for reciprocating

compressors. Never operate a reciprocating compressor

without a flywheel.

Drivers should be selected so the compressor operates

between 350 to 825 RPM. The unit must not be operated

without the flywheel or severe torsional imbalances will result

that could cause vibration and high horsepower requirement.

The flywheel should never be replaced by another pulley

unless it has a higher WK

2

value than the flywheel.

A humid climate can cause problems, particularly in

explosion proof motors. The normal breathing of the

motor, and alternating between being warm when running

and being cool when stopped, can cause moist air to be

drawn into the motor. This moist air will condense, and

may eventually add enough water inside the motor to

cause it to fail. To prevent this, make a practice of running

the motor at least once a week on a bright, dry day for an

hour or so without the V-belts. In this period of time the

motor will heat up and vaporize the condensed moisture,

driving it from the motor. No motor manufacturer will

guarantee their explosion proof or totally enclosed

(TEFC) motor against damage from moisture.

For installation with engine drivers, thoroughly review

instructions from the engine manufacturer to assure the

unit is properly installed.

2.6. Crankcase Lubrication

Non-detergent oil is recommended for Corken vertical

compressors. Detergent oils tend to keep wear particles

and debris suspended in the oil, whereas non-detergent

oils let them settle in the bottom of the crankcase.

When non-detergent oils are not available, detergent

oils may usually be successfully substituted, although

compressors handling ammonia, amine, or imine gases

are notable exceptions. These gases react with the

detergent and cause the crankcase oil to become

corrosive and contaminated. Figures 2.6A and 2.6B show

recommended oil viscosities and crankcase capacities.

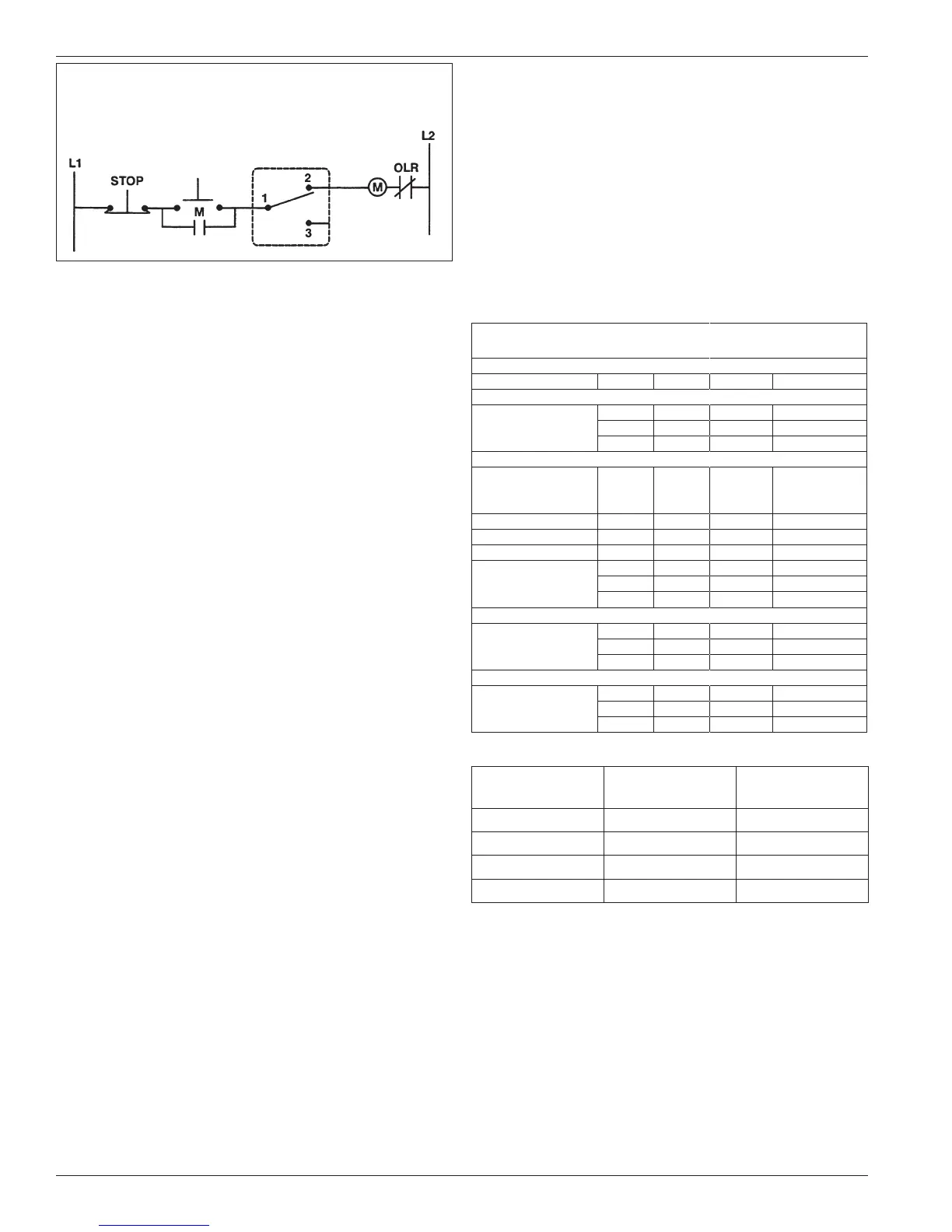

Acceptable Crankcase Oil Products

for Corken Compressors

Constant Weight - Non-Detergent - R&O Inhibited

Oil product ISO VI SAE Ambient Temp.

Exxon

®

TERESSTIC

100 95 30 65° – 100° F

68 95 20+ 45° – 70° F

46 95 20 35° – 50° F

Mobil

®

RARUS 427

Reciprocating

Compressor Oil

100 95 30 65° – 100° F

DTE Oil Heavy Medium 68 95 20+ 45° – 70° F

Dectol R&O Oil 46 95 20 35° – 50° F

Conoco

®

Dectol R&O Oil

100 98 30 65° – 100° F

68 97 20+ 45° – 70° F

46 99 20 35° – 50° F

Texaco

®

Regal R&O Oil

100 92 30 65° – 100° F

68 97 20+ 45° – 70° F

46 102 20 35° – 50° F

Sun

®

SunVis 900 Oil

100 100 30 65° – 100° F

68 100 20+ 45° – 70° F

46 100 20 35° – 50° F

Figure 2.6A: Oil selection chart.

Compressor

Model

Approximate

Quarts

Capacity Liters

91 0.9 0.8

291 1.5 1.4

491 3.0 2.8

691/891 7.0 6.6

Figure 2.6B: Oil capacity chart.

Synthetic lubricants are generally not necessary. Please

consult your lubricate supplier if you are considering the

use of synthetic oil. To add oil, remove the name plate

and pour through the opening.

General Notes on Crankcase Oil

Corken gas compressors are used for a wide variety of

gases in a multitude of operating conditions. They are

used in all areas of the world from hot dusty deserts, to

humid coastal areas, to cold arctic climates. No single

crankcase oil or maintenance schedule is right for every

compressor installation. Availability of brands and grades

12

Loading...

Loading...