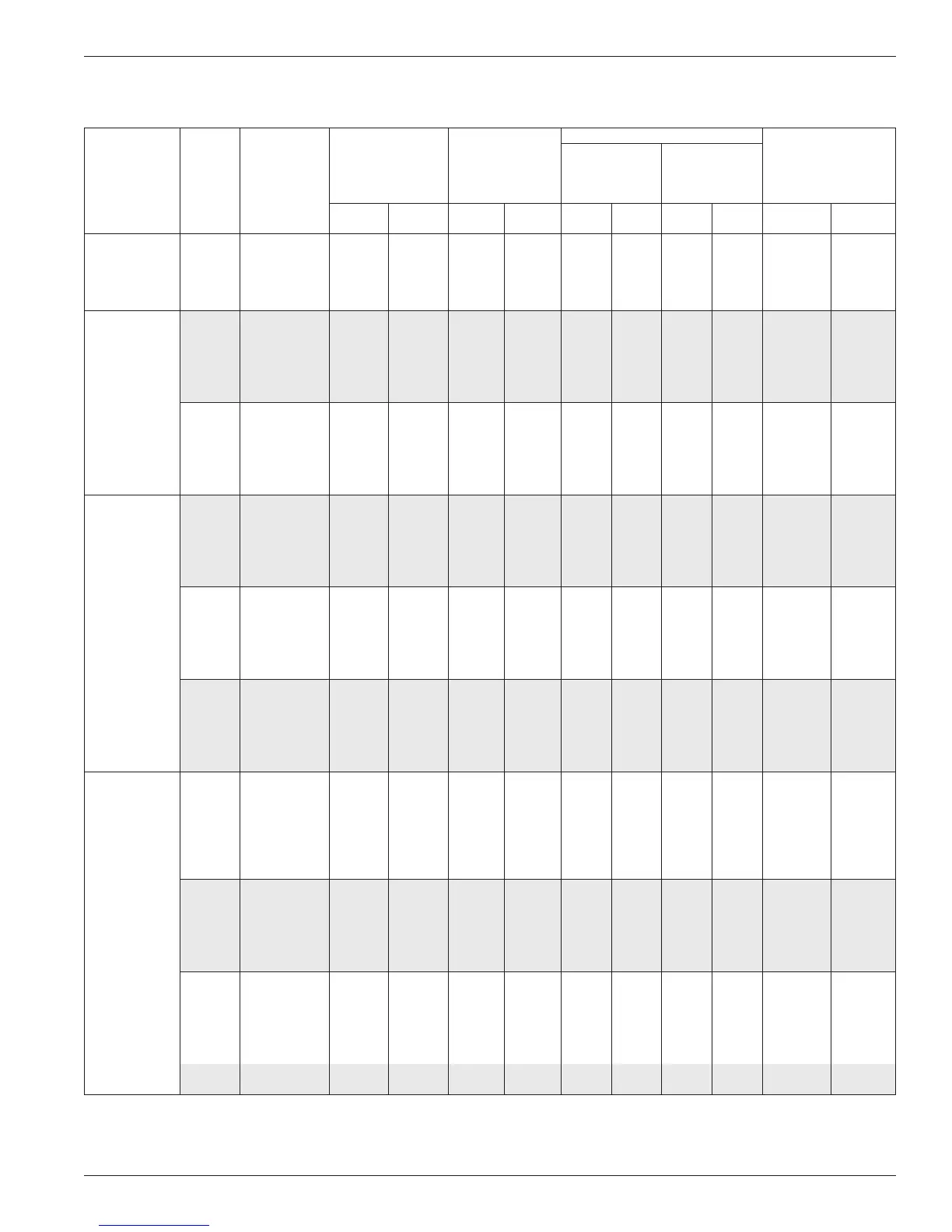

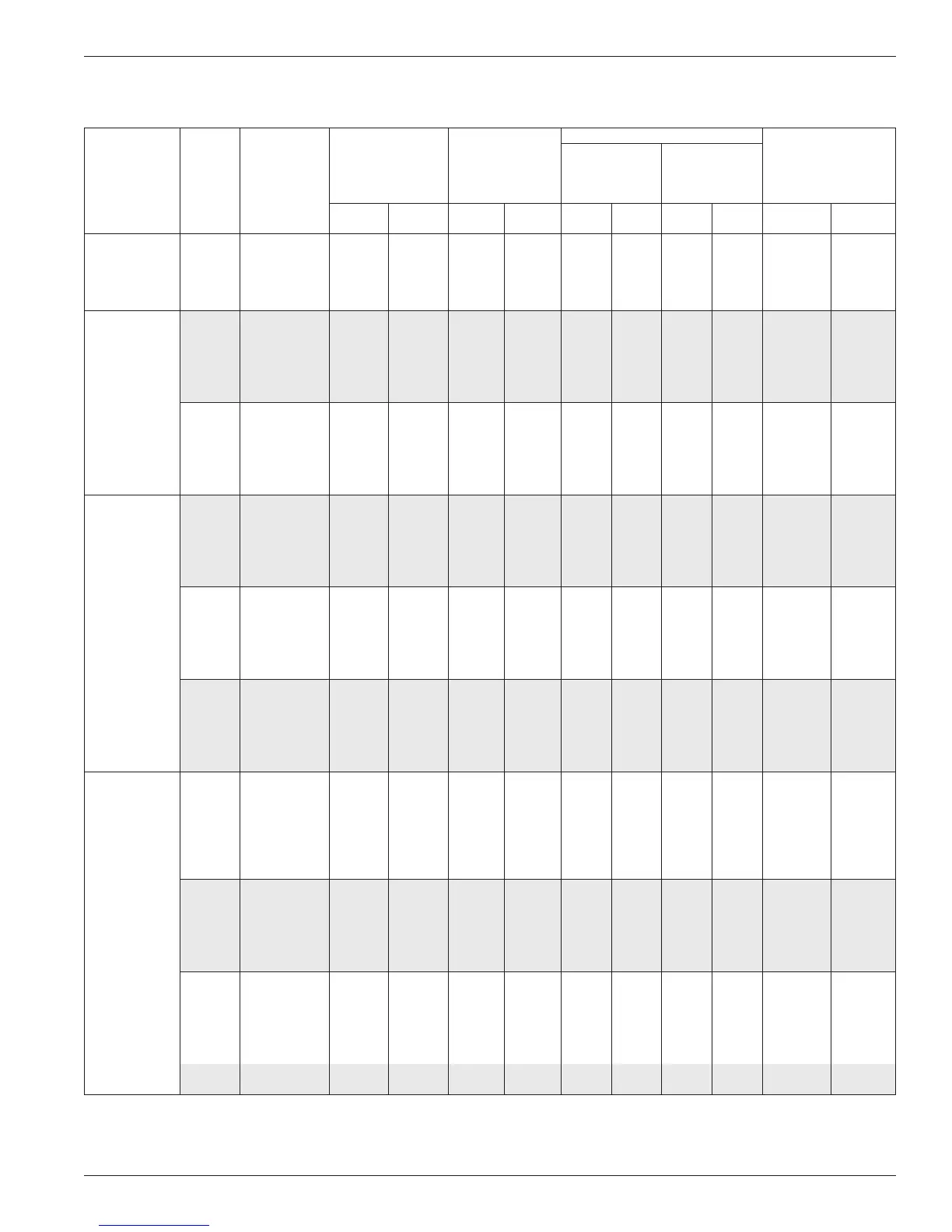

Appendix C—Compressor Selection

Butane Compressor Selection Table

Service

Capacity

gpm

1

Displacement

cfm

Compressor

Driver Sheave

Size Pitch

Diameter

(inches)

2

Driver Horsepower

Piping Size

3

Liquid

Transfer With

Residual Vapor

Recovery

Liquid Transfer

Without

Residual Vapor

Recovery

Model RPM

1,750

RPM

1,450

RPM

100°F 80°F 100°F 80°F Vapor Liquid

Small bulk

plants

13 4 91 400 A 3.0 B 3.6 3 3 3 3 3/4 1-1/4

17 5 91 505 B 3.8 B 4.6 3 3 3 3 3/4 1-1/4

20 6 91 590 B 4.6 B 5.6 3 3 3 3 1 1-1/4

24 7 91 695 B 5.4 B 6.6 5 5 5 5 1 1-1/2

23 7 291 345 A 3.0 A 3.6 2 2 2 2 1 1-1/2

Unloading

single tank car

or transport

27 8 91 800 B 6.2 B 7.4 5 5 5 5 1 1-1/2

26 8 291 390 A 3.4 B 4.0 2 2 2 2 1 1-1/2

30 9 291 435 A 3.8 B 4.6 3 3 3 3 1 1-1/2

33 10 291 490 B 4.4 B 5.2 3 3 3 3 1 2

36 11 291 535 B 4.8 B 5.8 3 3 3 3 1 2

39 12 291 580 B 5.2 B 6.2 5 3 5 3 1 2

42 13 291 625 B 5.6 B 6.6 5 5 5 5 1-1/4 2

47 14 291 695 B 6.2 B 7.4 5 5 5 5 1-1/4 2

50 15 291 735 B 6.6 B 8.0 5 5 5 5 1-1/4 2-1/2

50 15 491 345 A 3.0 A 3.6 5 5 5 5 1-1/4 2-1/2

53 16 291 780 B 7. 0 B 8.6 7-1/2 5 7-1/2 5 1-1/4 2-1/2

53 16 491 370 A 3.2 A 3.8 5 5 5 5 1-1/4 2-1/2

Unloading

two or more

tank cars at

one time or

large transport

with excess

flow valves

of adequate

capacity

56 17 491 390 A 3.4 B 4.0 5 5 5 5 1-1/4 3

60 18 491 415 A 3.6 B 4.4 5 5 5 5 1-1/4 3

63 19 491 435 A 3.8 B 4.6 5 5 5 5 1-1/4 3

65 20 491 445 B 4.0 B 4.8 5 5 5 5 1-1/4 3

68 21 491 470 B 4.2 B 5.0 5 5 5 5 1-1/4 3

71 22 491 490 B 4.4 B 5.2 7-1/2 5 7-1/2 5 1-1/4 3

75 23 491 515 B 4.6 B 5.6 7-1/2 5 7-1/2 5 1-1/4 3

77 24 491 535 B 4.8 B 5.8 7-1/2 7-1/2 7-1/2 7-1/2 1-1/4 3

81 25 491 560 B 5.0 B 6.0 7-1/2 7-1/2 7-1/2 7-1/2 1-1/4 3

84 26 491 580 B 5.2 B 6.2 7-1/2 7-1/2 7-1/2 7-1/2 1-1/4 3

87 27 491 605 B 5.4 B 6.4 7-1/2 7-1/2 7-1/2 7-1/2 1-1/4 3

91 28 491 625 B 5.6 B 6.6 7-1/2 7-1/2 7-1/2 7-1/2 1-1/2 3

94 29 491 650 B 5.8 B 7. 0 10 7-1/2 10 7-1/2 1-1/2 3

97 30 491 670 B 6.0 10 7-1/2 10 7-1/2 1-1/2 3

94 30 691 400 B 4.4 B 5.2 7-1/2 7-1/2 7-1/2 7-1/2 1-1/2 3

100 31 491 695 B 6.2 B 7.4 10 7-1/2 10 7-1/2 1-1/2 3

98 31 691 420 B 4.6 B 5.6 10 7-1/2 10 7-1/2 1-1/2 3

107 32 491 740 B 6.6 B 8.0 10 10 10 10 1-1/2 3

Unloading

large tank

cars, multiple

vessels, barges

or terminals

103 32 691 440 B 4.8 B 5.8 10 7-1/2 10 7-1/2 1-1/2 3

110 33 491 760 B 6.8 B 8.0 10 10 10 10 1-1/2 3

113 34 491 780 B 7. 0 B 8.6 10 10 10 10 1-1/2 3

107 34 691 455 B 5.0 B 6.0 10 10 10 10 1-1/2 3

111 35 691 475 B 5.2 B 6.2 10 10 10 10 1-1/2 3

119 36 491 825 B 7.4 B 8.6 15 10 15 10 1-1/2 3

116 36 691 495 B 5.4 A 6.4 10 10 10 10 1-1/2 3

120 38 691 510 B 5.6 B 6.8 10 10 10 10 1-1/2 4

124 39 691 530 B 5.8 B 7. 0 10 10 10 10 1-1/2 4

129 41 691 550 B 6.0 A 7.0 10 10 10 10 1-1/2 4

133 42 691 565 B 6.2 B 7.4 10 10 10 10 2 4

137 43 691 585 B 6.4 A 7.4 10 10 10 10 2 4

142 45 691 605 B 6.6 B 8.0 15 10 15 10 2 4

145 46 691 620 B 6.8 15 10 15 10 2 4

150 47 691 640 B 7. 0 A 8.2 15 10 15 10 2 4

158 48 691 675 B 7.4 B 8.6 15 15 15 15 2 4

171 54 691 730 B 8.0 B 9.4 15 15 15 15 2 4

184 58 691 785 B 8.6 15 15 15 15 2 4

193 60 691 820 TB 9.0 A 10.6 15 15 15 15 2 4

260 82.1 D/FD891 580 5 V 7.1 5V 8.5 20 20 20 20 3 6

359 113. 3 D/FD891 800 5V 9.75 5V 11.8 25 25 25 25 3 6

1

The capacities shown are based on 70°F, but will vary depending upon piping, fittings used, product being transferred and temperature. The factory can

supply a detailed computer analysis if required.

2

Driver sheaves: 91 - 2 belts; 291, 491 - 3 belts; 691 - 4 belts.

3

The piping sizes shown are considered minimum. If the length exceeds 100 ft., use the next larger size.

Consult factory for compressors with higher flows.

39

Loading...

Loading...