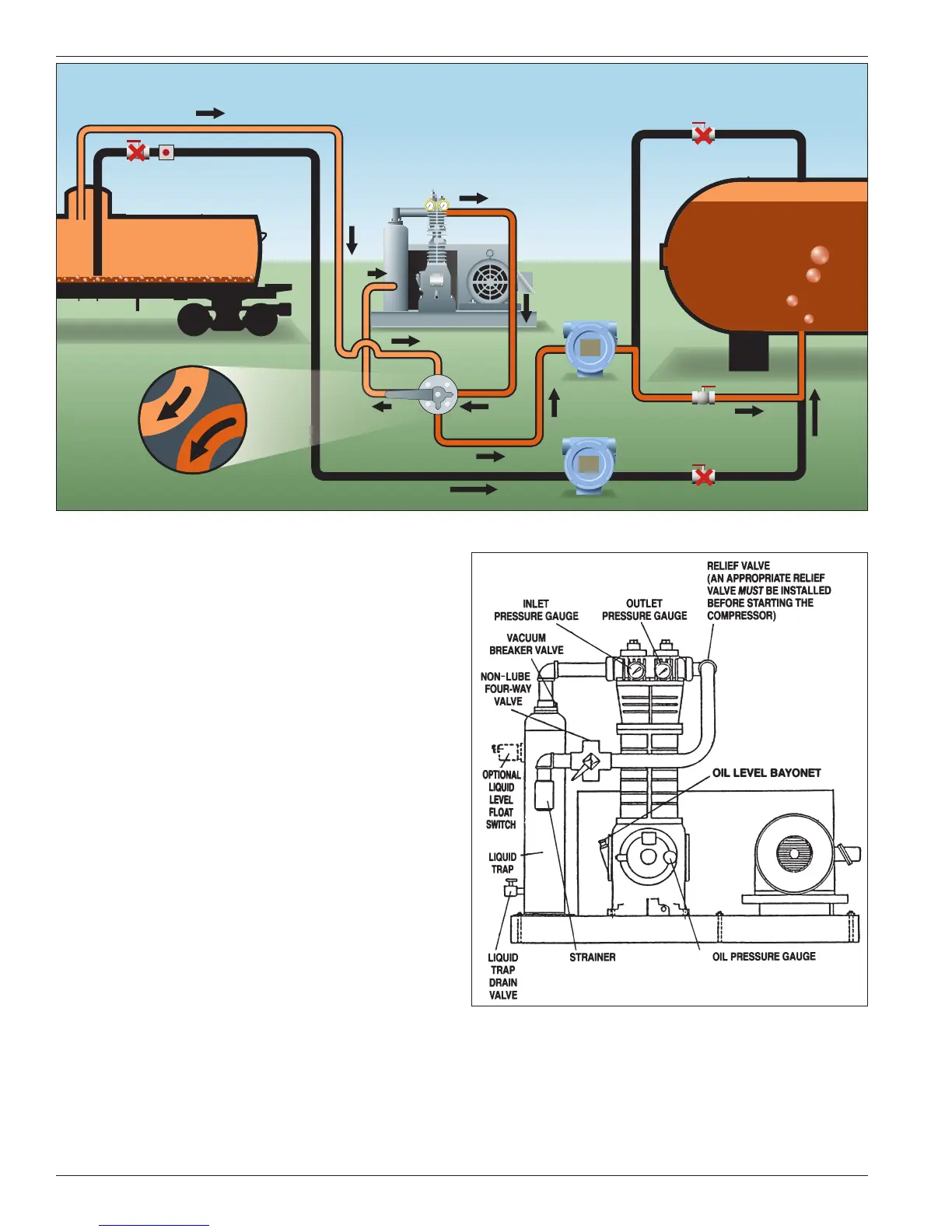

Vapor is

bubbled

through liquid

to help cool and

recondense it

Removing vapor from

tank causes liquid heel

to boil into vapor

Liquid line is valved closed

during vapor recovery.

Four Way Valve Position 2

Vapor Line

Vapor Line

Liquid Line

(3.8 to 4.5 bars). A good rule of thumb is not to operate

beyond the point at which the inlet pressure is one-

fourth the discharge pressure. Some liquids are so

expensive that further recovery may be profitable, but

care should be taken that the ratio of absolute discharge

pressure to absolute inlet pressure never exceeds 7 to

1. Further excavation of very high value products would

require a Corken two-stage gas compressor.

Invariably, there is some liquid remaining in the tank

after the liquid transfer operation. This liquid “heel”

must be vaporized before it can be recovered, so

do not expect the pressure to drop immediately.

Actually, more vapor will be recovered during the first

few minutes while this liquid is being vaporized than

during the same period of time later in the operation.

Remember that more than half of the economically

recoverable product is usually recovered during the

first hour of operation on properly sized equipment.

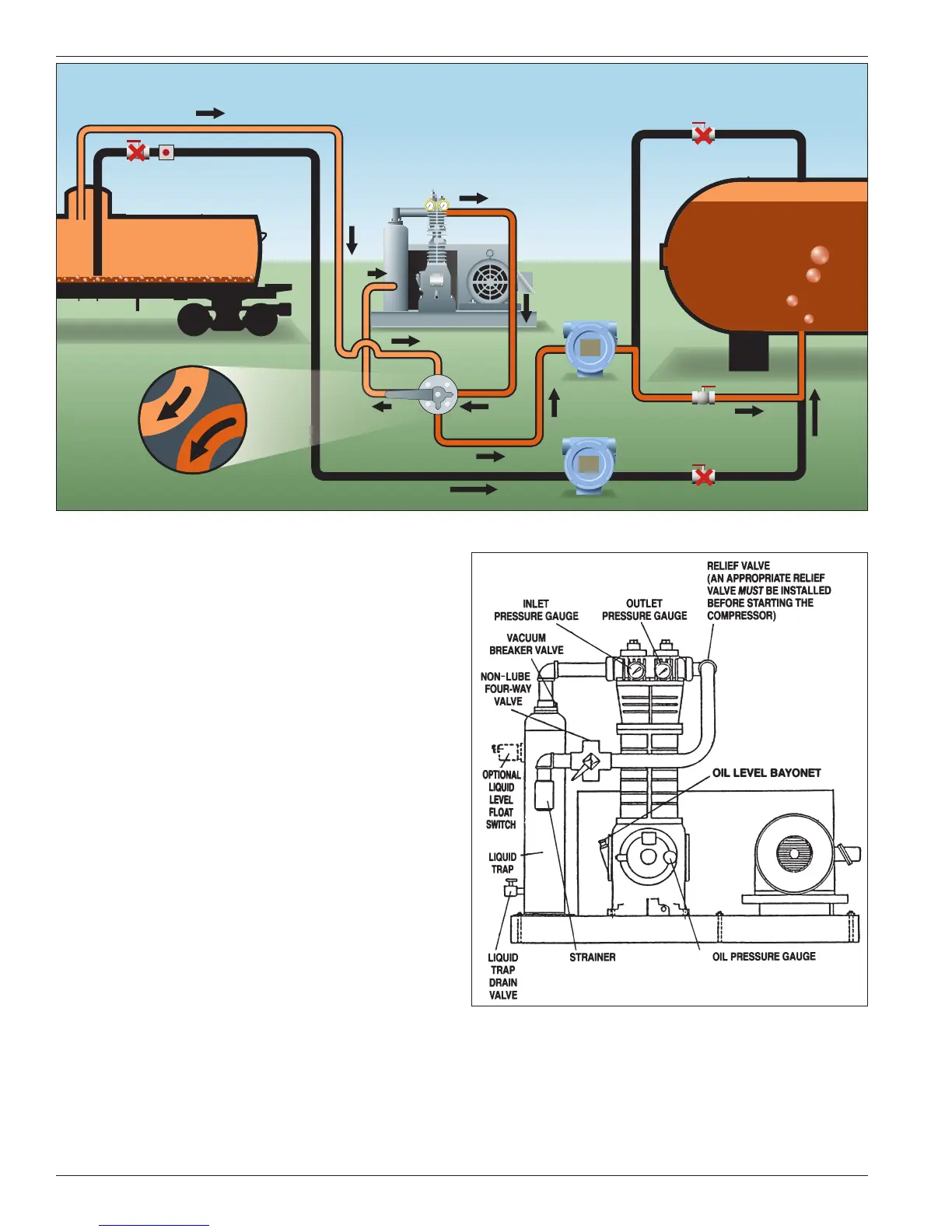

1.3 Compressor

Construction Features

The Corken liquid transfer-vapor recovery compressor

is a vertical single-stage, single-acting reciprocating

compressor designed to handle flammable gases

like LPG and toxic gases such as ammonia. Corken

compressors can handle these potentially dangerous

gases because the LPG/NH

3

is confined in the

compression chamber and isolated from the crankcase

and the atmosphere. A typical liquid transfer-vapor

recovery compressor package is shown in figure 1.3A.

Figure 1.3A: 107-style compressor mounting.

Corken gas compressors are mounted on oil lubricated

crankcases remaining at atmospheric pressure. Crankshafts

are supported by heavy-duty roller bearings and the

connecting rods ride the crankshaft on journal bearings.

With the exception of the small size model 91 compressor,

all compressor crankcases are lubricated by an automotive

type oil pressure system. An automatically reversible gear

Figure 1.2A: Residual vapor recovery.

6

Loading...

Loading...