107 style compressors are usually connected using a five-

valve (figure 2.3B) or three-valve manifold (figure 2.3C).

The five-valve manifold allows the storage tank to be

both loaded and unloaded. The three-valve manifold only

allows the storage tank to be loaded. Adequate sizing of

the liquid and vapor lines is essential to limit the pressure

drop in the system to a reasonable level (20 psi or less).

The line size helps determine the plant capacity almost

as much as the size of the compressor, and liquid line

sizes are a bigger factor than vapor lines. If the pressure

gauges on the head indicate more than a 15 to 20 psi

(1.0 to 1.4 bars) differential between the inlet and outlet

pressures, the line sizes may be too small or there is too

much piping restriction. The less restriction in the piping,

the better the flow. Appendix C shows recommended

pipe sizes for typical LPG/NH

3

compressor installation.

A tank car unloading riser should have two liquid hoses

connected to the car liquid valves. If only one liquid

hose is used, the transfer rate will be slower and there

is a good possibility that the car’s excess flow valve

may close.

Since the heat of compression plays an important part in

rapid liquid transfer, the vapor line from the compressor to

the tank car or other unloading container should be buried

or insulated to prevent the loss of heat and the compressor

should be located as near as possible to the tank being

emptied. In extremely cold climates, if the line from the

storage tank to the compressor is over 15 feet (4.6 meters)

long, it should be insulated to lessen the possibility of

vapors condensing as they flow to the compressor. The

vapor recovery discharge line should not be insulated.

Placing the compressor as close as possible to the tank

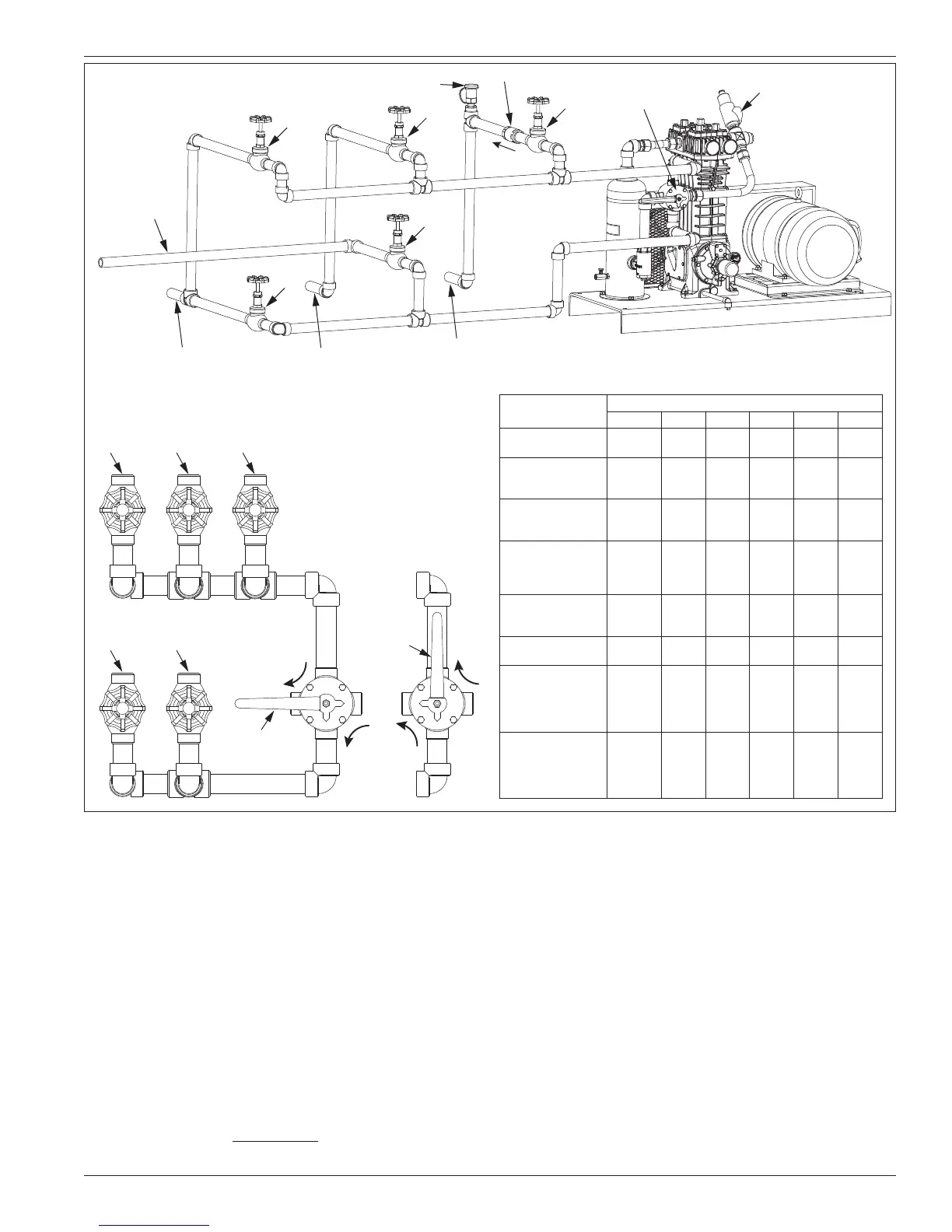

Hydrostatic relief valve

Back check valve

Relief valve

4-Way valve

C

Vapor line to liquid phase

in storage tank

B

Vapor line to truck

trailer or tank

(local transport)

Vapor line to

rail car

(inbound bulk

transport)

Vapor line to gas phase

in storage tank

D

E

A

Bury or

insulate in

cold climate

areas

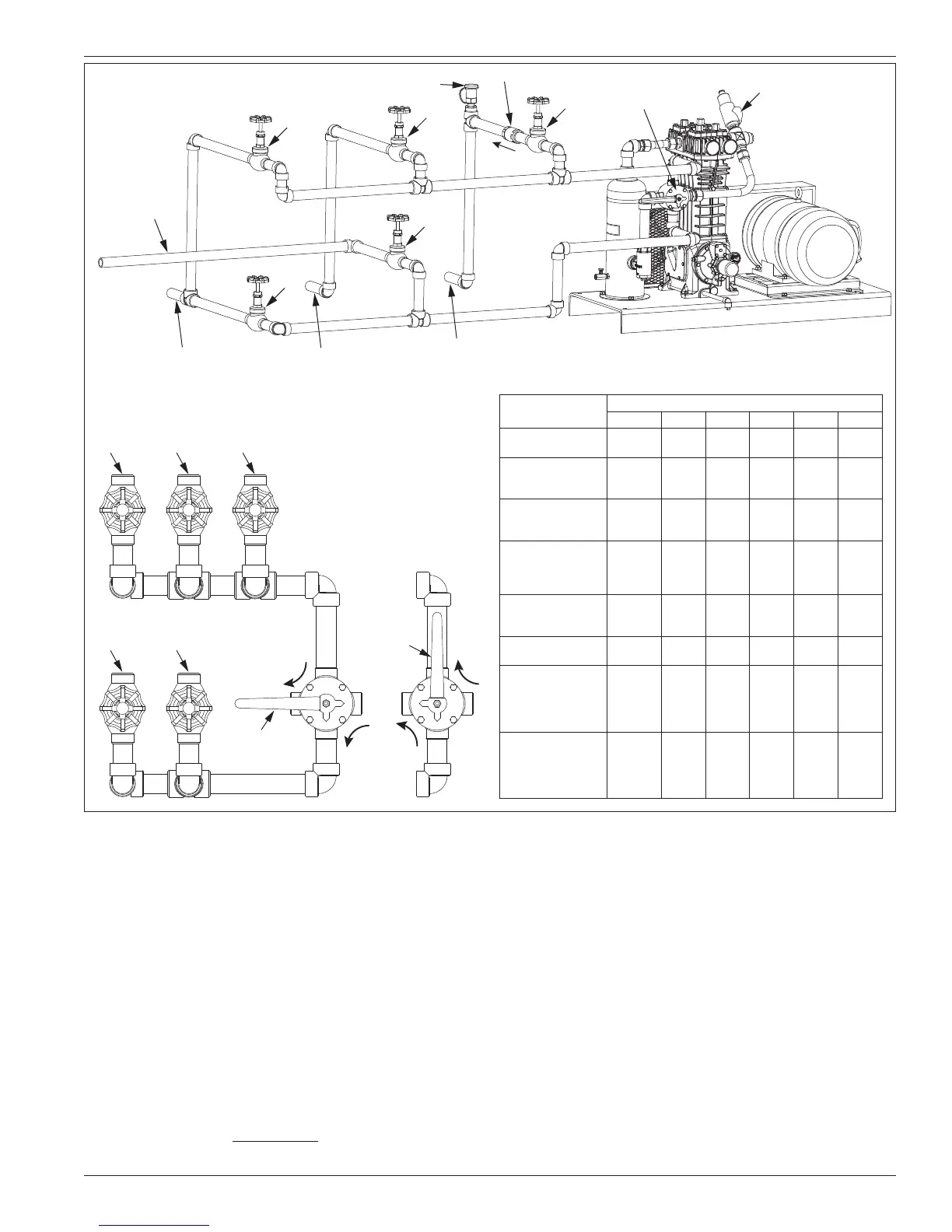

4-Way Valve

Position 1

E B

4-Way Valve

Position 2

Service to Perform

Valve Position

4-way A B C D E

1. Unload tank car

into storage tank

Position

One

Open Open Close Close Close

2. Recover vapors

from tank car into

storage tank

Position

Two

Close Open Open Close Close

3. Unload transport

or truck into

storage tank

Position

One

Open Close Close Close Open

4. Recover vapors

from transport or

truck into storage

tank

Position

Two

Close Close Open Close Open

5. Load truck or

field tank from

storage tank

Position

Two

Open Close Close Close Open

6. Load truck or field

tank from tank car

Position

One

Close Open Close Open Close

7. Equalize between

tank car and

storage tank

without using

vapor pump

— Open Open Close Open Open

8. Equalize between

truck or field tank

and storage tank

without using

vapor pump

— Open Close Close Open Close

4-way Valve Operation

Figure 2.3B: Five valve manifold piping system.

9

Loading...

Loading...