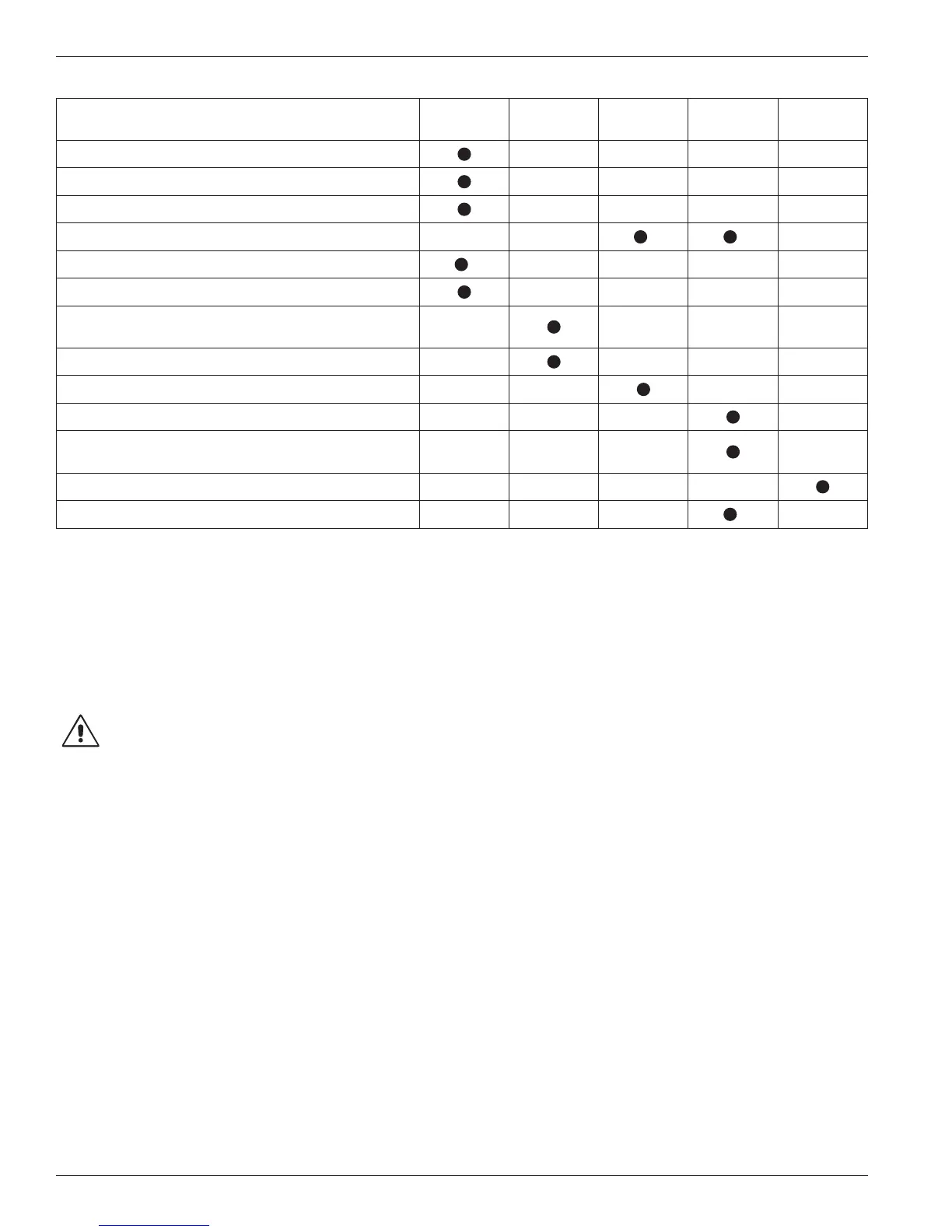

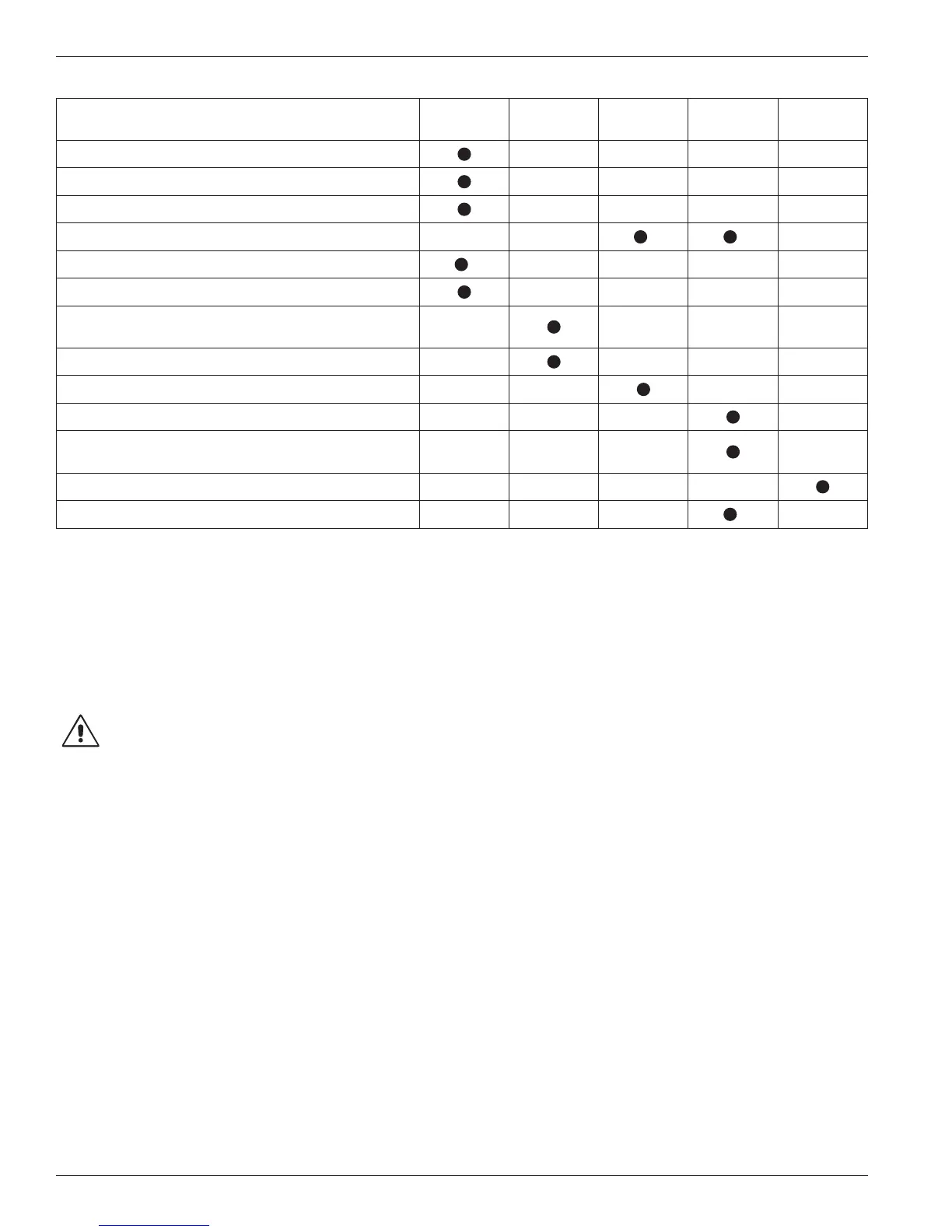

Item to Check Daily Weekly Monthly

Six

Months

Yearly

Crankcase oil pressure

Compressor discharge pressure

Overall visual check

Crankcase oil level

1 1

Drain liquid from accumulation points

2

Drain distance pieces

Clean cooling surfaces on compressor and

intercooler (if any)

Lubricator supply tank level (if any)

Check belts for correct tension

Inspect valve assemblies

Lubricate motor bearings in accordance with

manufacturers’ recommendations

Inspect motor starter contact points

Inspect piston rings

1

3

Chapter 4—Routine Maintenance Chart

1

Change oil every 2,200 hours of operation or every 6 months, whichever occurs first. If the oil is unusually dirty, change it as often as needed to maintain a

clean oil condition. Change replacement filter 4225 with every oil change.

2

Liquid traps should be drained prior to startup.

3

Piston ring life varies greatly, depending on application, gas, and operating pressures. Consult factory for additional recommendations for your specific

application.

Chapter 5—Routine Service and

Repair Procedures

CAUTION: Always relieve pressure in the unit

before attempting any repairs. After repair,

the unit should be pressure tested and checked for

leaks at all joints and sealing surfaces.

If routine maintenance is performed as listed in chapter

4, repair service on your Corken gas compressor is

generally limited to replacing valves or piston rings.

When it comes time to order replacement parts, be sure

to consult the part details appendix in the back of this

Installation, Operation & Maintenance (IOM) manual for a

complete list of part numbers and descriptions.

5.1 Valves

Test the compressor valves by closing the inlet piping

valves while the unit is running; however, do not allow

the machine to operate in this way very long. If the

inlet pressure gauge does not drop to zero almost

immediately, one or more of the valves is probably either

damaged or dirty. It is possible, of course, that the

pressure gauge itself is faulty.

Inspect valves for breakage, corrosion, debris, and

scratches on the valve disc. In many cases, valves may

simply be cleaned and reinstalled. If the valves show

any damage, they should be repaired or replaced.

Replacement is usually preferable, although individual

parts are available. If valve discs are replaced, seats

should also be lapped until they are perfectly smooth.

A maximum of .005 inch can be removed during the

lapping process. If more than .005 inch must be removed

to achieve a smooth surface, the valve should be

discarded. If discs are replaced without relapping the

seat, rapid wear and leakage may occur.

Each suction and/or discharge valve assembly is easily

removed as a unit for inspection. If any part of the valve

assembly is broken, the valve assembly should be replaced.

See valve assembly parts details in the appendices for a

complete list of part numbers and descriptions.

If a valve is leaking due to dirt or any other foreign

material that keeps the valve plate and seat from sealing,

the valve may be cleaned and reused. New gaskets and/

or O-rings should be used to assure a good seal.

The valve holddown assemblies and valve assemblies on

the following pages show the various specifications used

on models 91, 291, 491, 691 and 891 compressors. Since

more than one suction valve arrangement is available for

each model of compressor, it is necessary to know your

complete model number so you can identify the valve

18

Loading...

Loading...