API Service

The American Petroleum Institute (API) grades motor

oils (oils designed for use in engines in cars and trucks)

with a two letter classification. Oils with API grades “SA”

through “SH” are obsolete and should never be used

in modern engines or gas compressors. Unfortunately,

motor oils with an “SA” and “SB” ratings are still readily

available at parts stores, service stations, and other

retail outlets at low prices. These are low quality oils and

should NEVER be used in Corken compressors. If motor

oil is used in a Corken compressor, it should have an

API Service of SJ or better. Multigrade motor oils such

as 10W-40 tend to have a higher viscosity index.

A

P

I

S

E

R

V

I

C

E

S

N

E

N

E

R

G

Y

C

O

N

S

E

R

V

I

N

G

SAE

5W-30

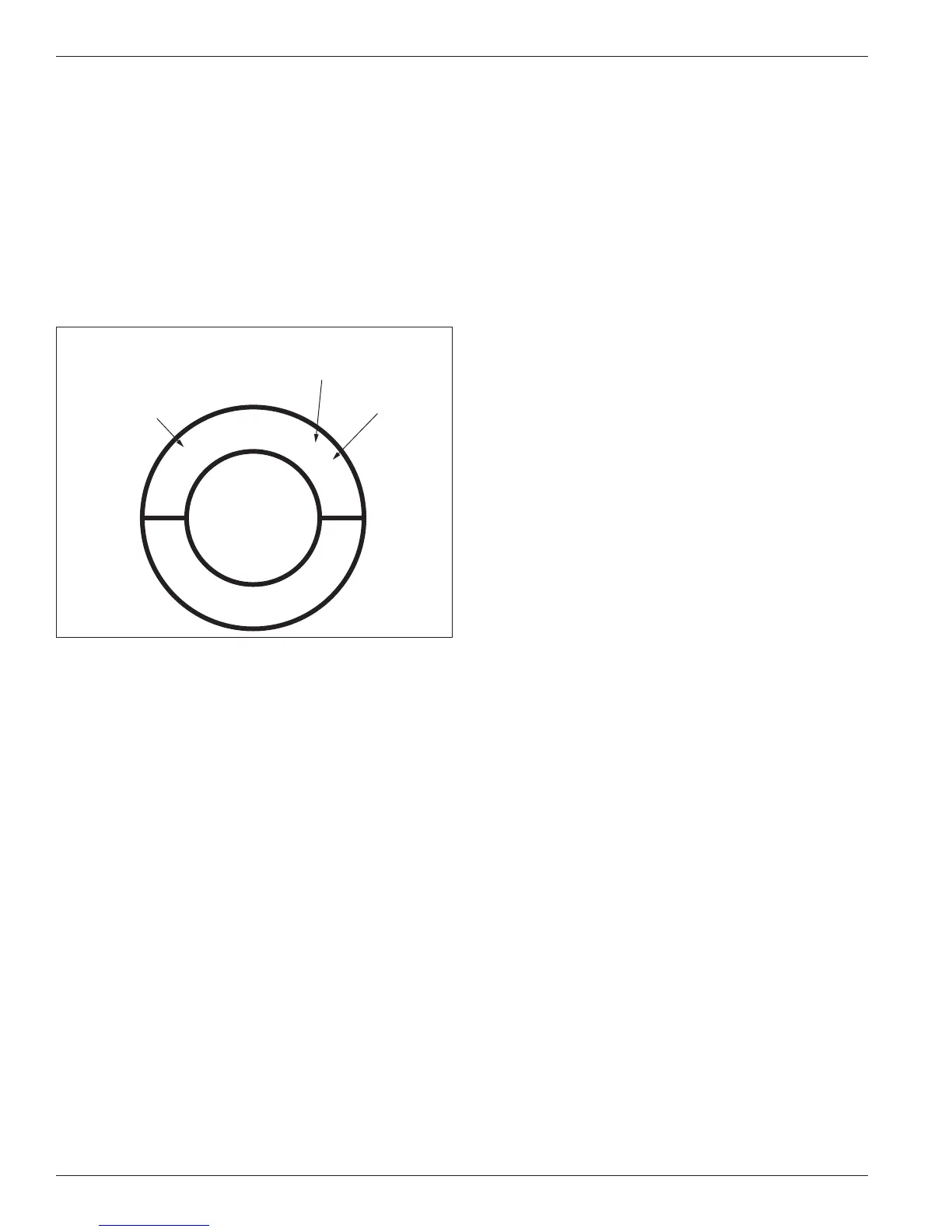

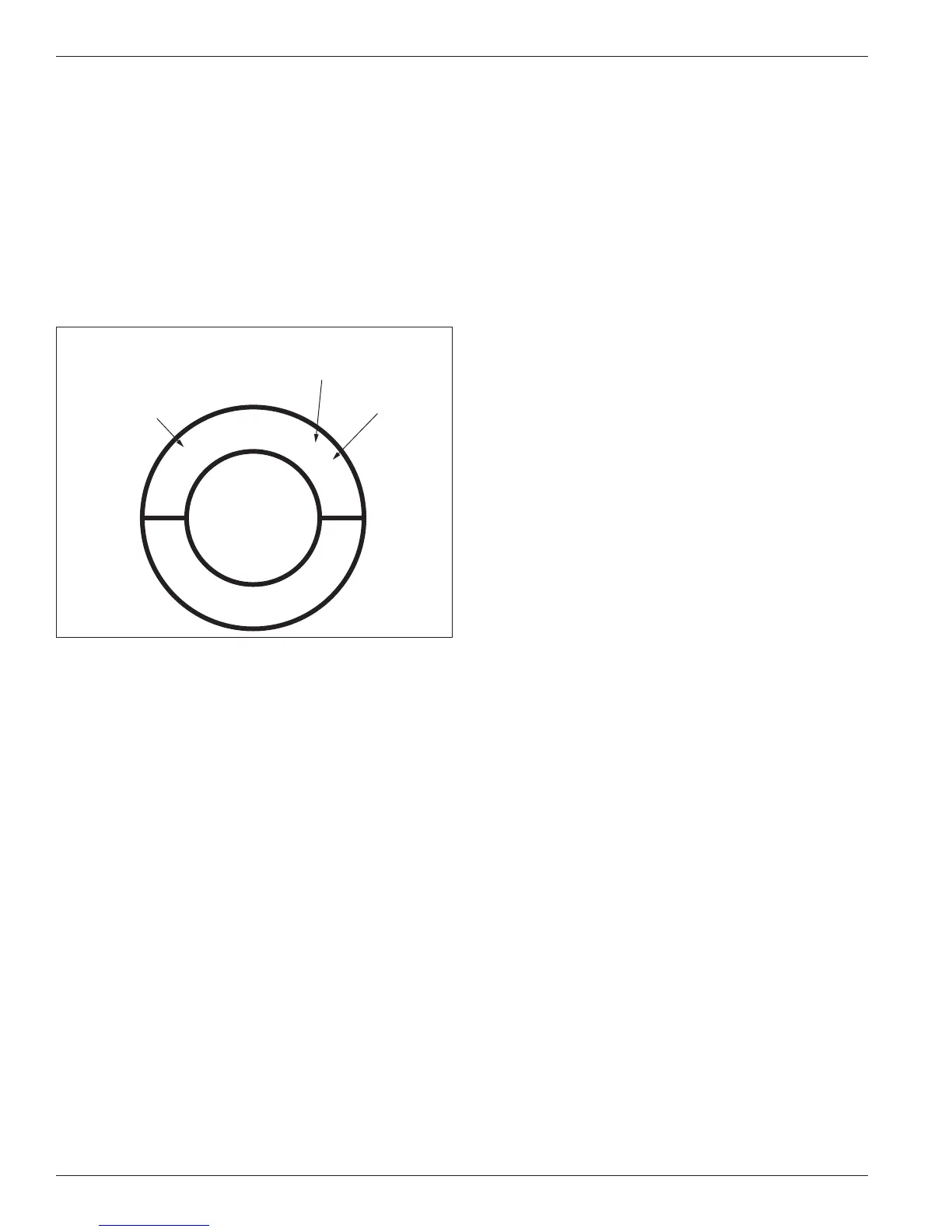

API (American

Petroleum Institute)

Quality rating

Service classification

S=gasoline engine

C=diesel engine

Example of API “Donut” symbol used on motor oil.

Oil suppliers post product data sheets on line that

contain various physical properties of the oil , and the

API Service classification. If there is any doubt, do not

use the oil.

Oil Change Intervals

Oil change intervals can vary significantly depending

on local environmental conditions, the gas being

compressed, and the oil being used. Unless there are

factors that shorten the life of the oil, the following

recommendations apply:

Conventional oil: 2200 hours or 6 months – whichever

comes first

Synthetic oil: 6000 - 8000 hours* or one year –

whichever comes first

*Oil change intervals in this range should be confirmed via oil analysis.

Factors that shorten the life of the oil:

• Dirty or dusty environmental conditions that cause the

oil to become dirty or discolored

• Oil dilution caused by condensation or other liquids in

the gas stream (see below)

• Change in viscosity for any reason (various oil additives

can break down over time)

• Changing ambient temperature may cause the need for

a different viscosity

The oil should be changed as often as necessary

to maintain clean, undiluted oil. Each time the oil is

changed, the oil filter (Corken part number 4225) should

also be changed.

Ammonia Services

Never use a detergent oil in a compressor in ammonia

service. Ammonia will react with the detergent and cause

lubrication failure.

Oils that can be used in ammonia compressors:

• Royal Purple: Uni-Temp

• Phillips 66: Ammonia Compressor Oil

• Chevron: Capella P68

Crankcase Oil Heater Option

Corken offers a crankcase oil heater as an option on

all models except the small model 91. This heater is

available in 110V and 220V versions and is rated for Class

1, Division 1 and 2, Group B, C, D service. The heater

includes a thermostat set at 70°F (21.1°C).

If a crankcase heater is desired, it is best to order the

heater with the compressor (crankcase specification

“MH”). The mounting hole for the heater is not drilled

unless the heater is ordered with the compressor. It is

also possible to order the compressor with the hole

drilled (1" NPT), but without the heater (crankcase

specification “MR”). With this option, a customer can

supply their own heater.

2.7 Relief Valves

An appropriate relief valve must be installed at the

compressor discharge. On Corken 107-style mounted

units a relief valve should be fitted in the piping between

the compressor discharge and the four-way valve (see

figure 1.3A). Relief valves should be made of a material

compatible with the gas being compressed. Local codes

and regulations should be checked for specific relief

valve requirements. Also, relief valves may be required at

other points in the compressor’s system piping.

14

Loading...

Loading...