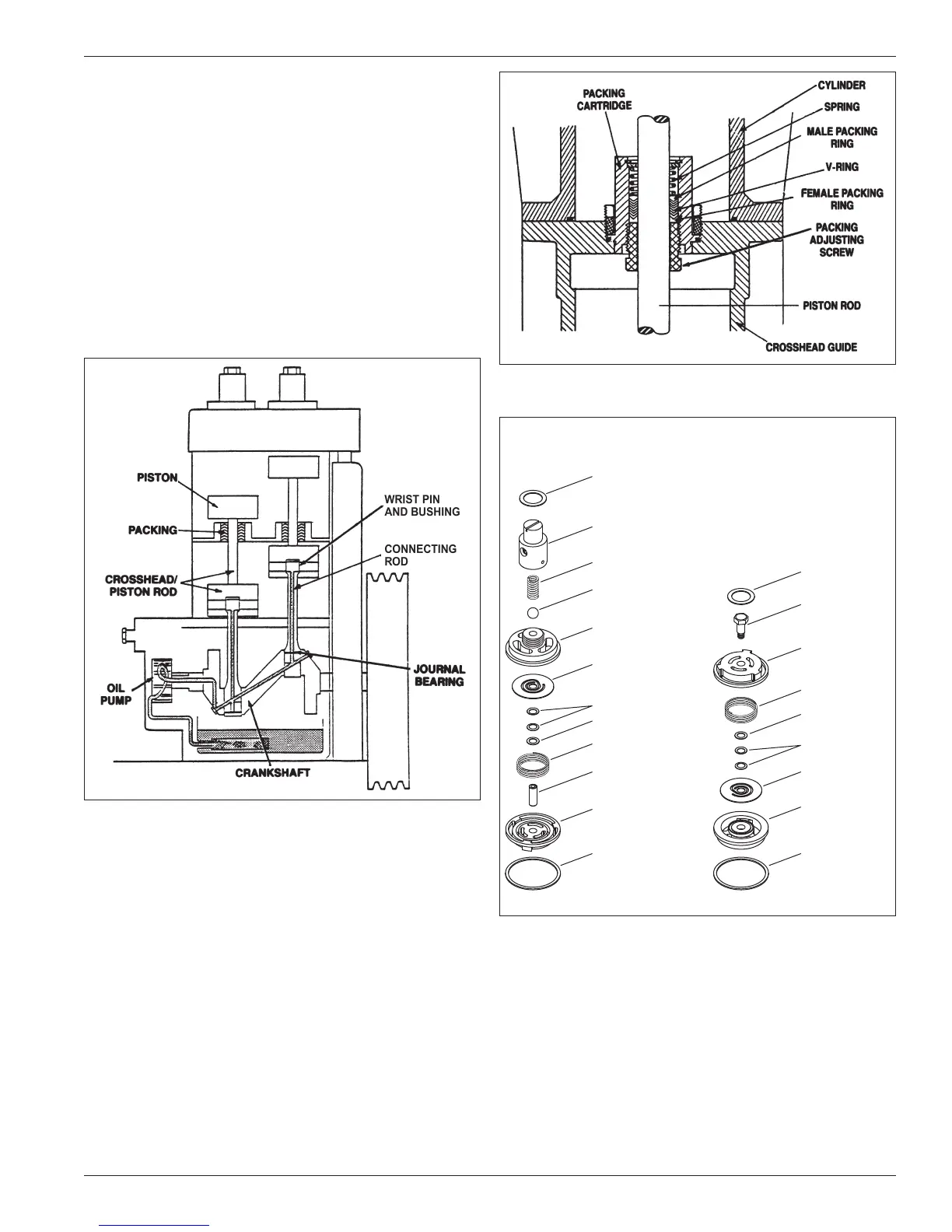

type oil pump circulates oil through passages in the

crankshaft and connection rod to lubricate the journal

bearings and wrist pins (see figure 1.3B). Sturdy iron

crossheads transmit reciprocating motion to the piston.

Corken’s automatically reversible oil pump design

allows the machine to function smoothly in either

direction of rotation.

Corken compressors use iron pistons locked to the piston

rod. The standard piston ring material is a glass-filled

PTFE polymer specially formulated for non-lubricated

services. Piston ring expanders are placed behind the

rings to ensure that the piston rings seal tightly against

the cylinder wall.

Figure 1.3B: Pressure lubrication system (not available on Model 91).

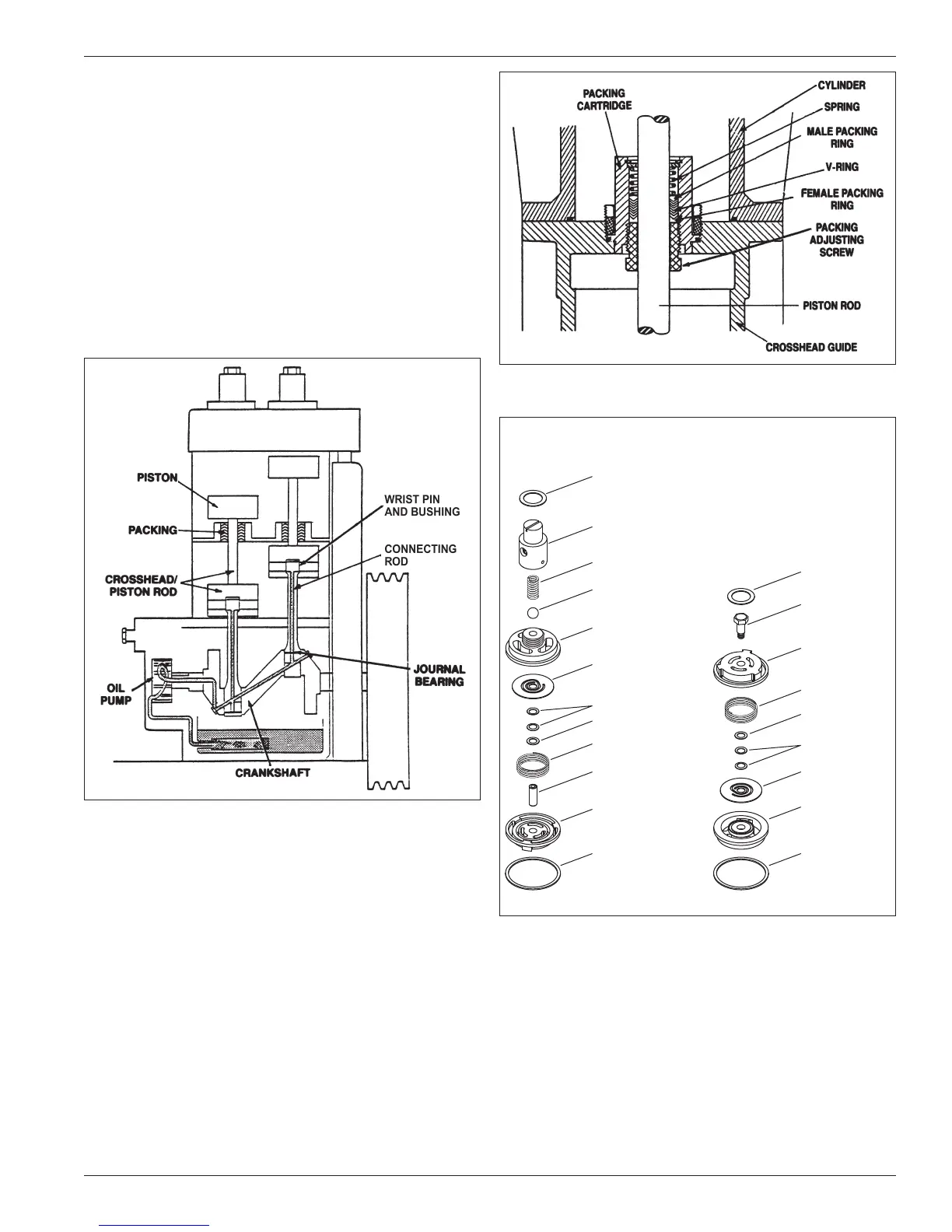

Piston rod packing is used to seal the gas in the

compression chamber and prevent crankcase oil from

entering the compressor cylinder. The packing consists

of several PTFE V-rings sandwiched between a male and

female packing ring and held in place by a spring (see

figure 1.3C).

The typical Corken compressor valve consists of a seat,

bumper, one or more spring/s and one or more valve/s

discs or plates as shown in figure 1.3D. Special heat-

treated alloys are utilized to prolong life of the valve in

punishing non-lubricated services. The valve opens

whenever the pressure on the seat side exceeds the

pressure on the spring side.

Gasket

Adjusting

screw

Relief ball spring

Relief ball

Suction valve

seat

Valve plate

Spacers

Washer

Spacers

Washer

Valve spring

Suction valve

post

Suction valve

bumper

Valve gasket

Gasket

Bolt

Discharge valve

bumper

Valve spring

Valve plate

Discharge valve

seat

Valve gasket

Suction Valve

Spec 3

Discharge Valve

All Specs

Figure 1.3C: Compressor sealing system

Figure 1.3D: Compressor sealing system

7

Loading...

Loading...