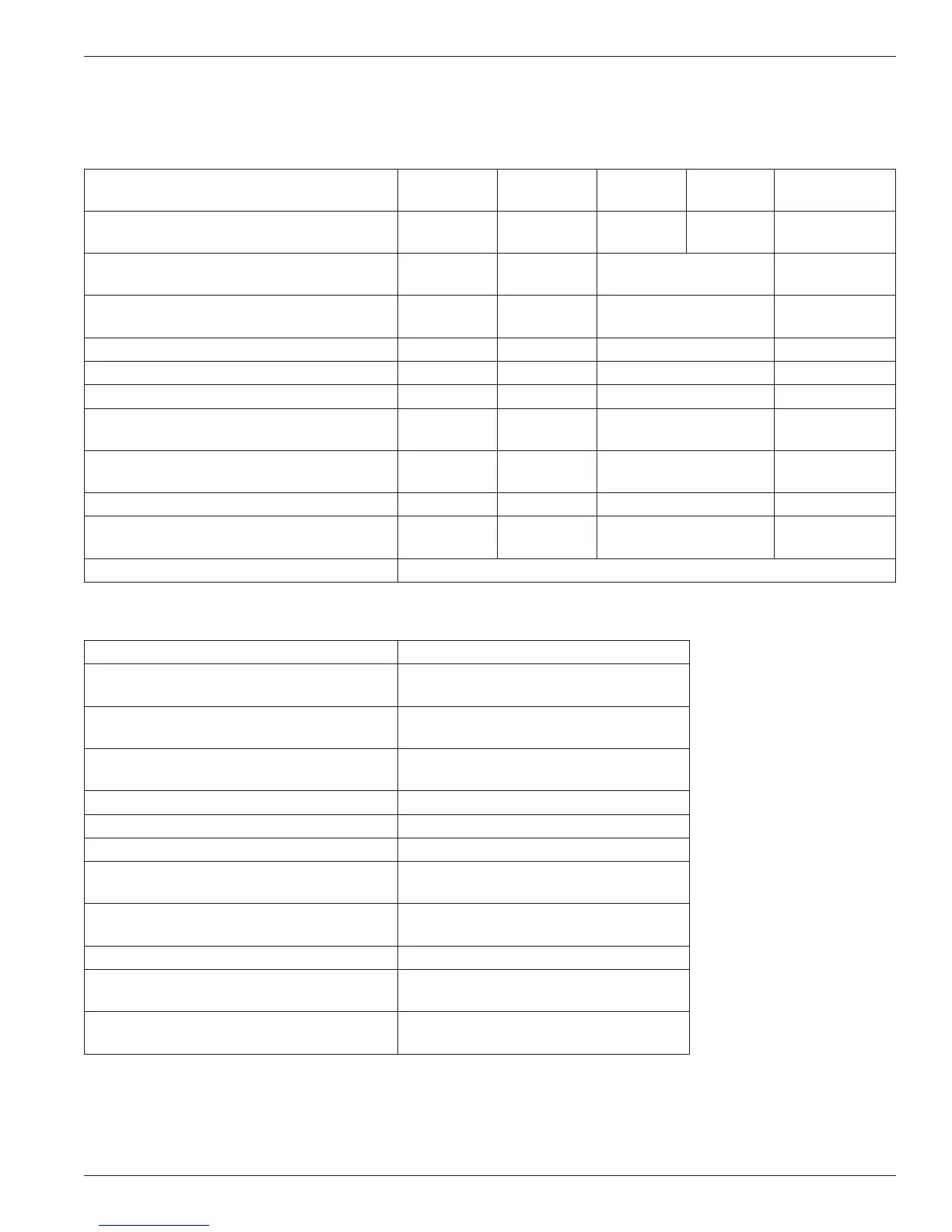

Appendix B—Specifications for Vertical Single and Double-Acting

Models 91–891

Clearances and Dimensions for Single-Acting Models

Model 91 291 490 491

691

(M crankcase)

“X” piston clearance figure 5.4A and 5.4B

1

0.020

0.044

0.020

0.044

0.000

0.024

0.020

0.044

0.025

0.040

Clearance from connecting rod bearing to

crankshaft journal

0.001

0.0025

0.001

0.0025

0.001

0.0025

0.0019

0.0035

Clearance from wrist pin to wrist pin

bushing

2

0.0006

0.0 011

0.0006

0.0 011

0.0006

0.0 011

0.0009

0.0015

Maximum cylinder bore diameter 3.009 3.009 4.011 4.515

Cylinder finish (RMS) 16–32 16–32 16–32 16–32

Minimum piston ring radial thickness 0.082 0.082 0.082 0.082

Maximum clearance from oil pump

adapter shaft to bushing

2

N/A 0.0050 0.0050 0.0050

Crankshaft end play

0.000

0.002

0.000

0.002

0.000

0.002

0.002

0.003

Maximum flywheel runout at O.D. 0.020 0.020 0.020 0.020

Maximum clearance from crosshead to

crosshead guide bore

0.011 0.011 0.012 0.013

Crosshead guide bore finish 32 RMS (limited number of small pits and scratches are acceptable)

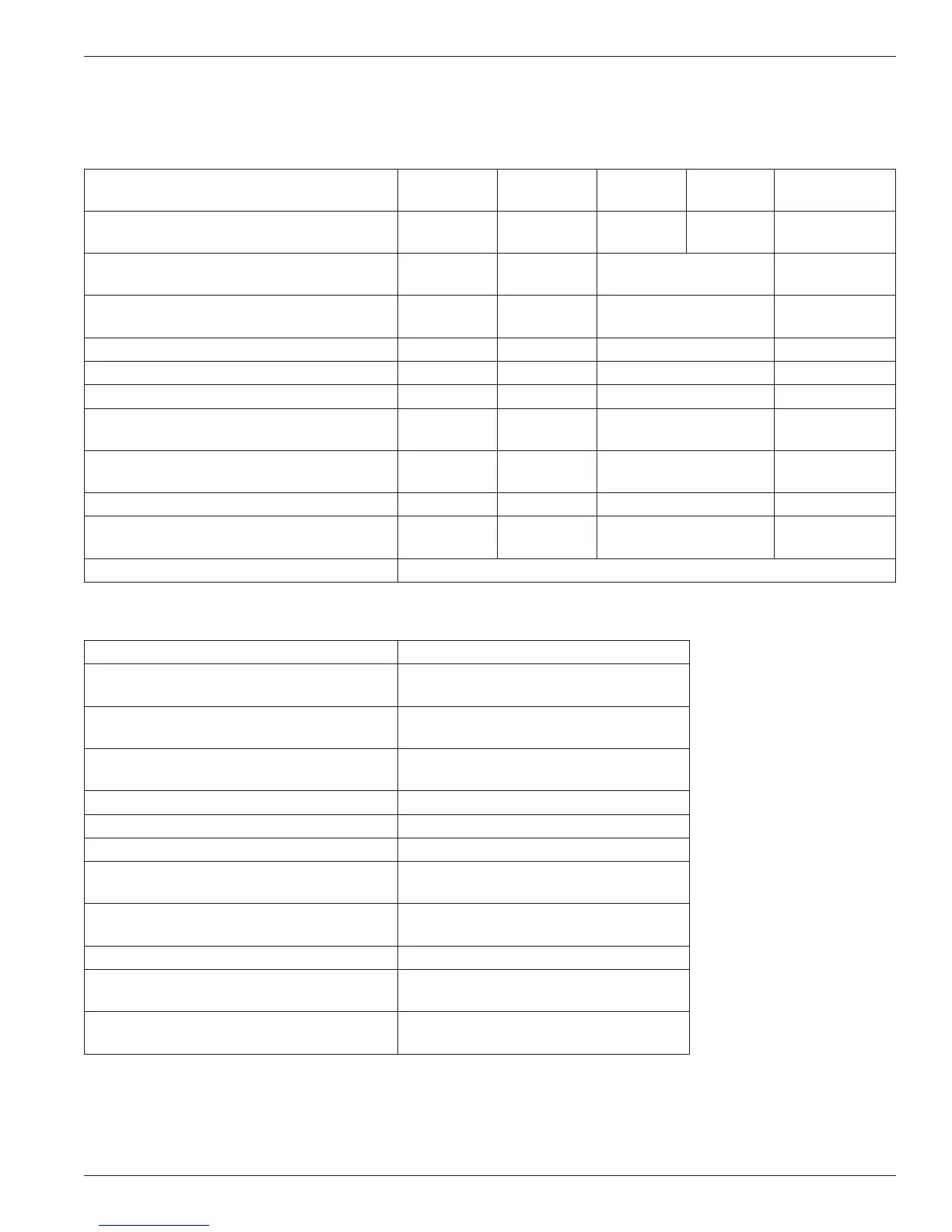

Clearances and Dimensions for Double-Acting Models

Model 891

“X” piston clearance figure 5.4A and 5.4B

1

0.010/0.020 (bottom)

0.084/0.104 (top)

Clearance from connecting rod bearing to

crankshaft journal

0.0019

0.0035

Clearance from wrist pin to wrist pin

bushing

2

0.0009

0.0015

Maximum cylinder bore diameter 4.515

Cylinder finish (RMS) 16–32

Minimum piston ring radial thickness 0.082

Maximum clearance from oil pump

adapter shaft to bushing

2

0.0050

Crankshaft end play

0.002

0.003

Maximum flywheel runout at O.D. 0.020

Maximum clearance from crosshead to

crosshead guide bore

0.008

Crosshead guide bore finish

32 RMS (limited number of small pits

and scratches are acceptable)

1

Clearances should be set with machine cold.

2

Dimensions for honing are included with new bushings (which must be installed, then honed).

35

Loading...

Loading...