5

1

4

2

5

8

6

3

2

Note

alignment

marks

7

9

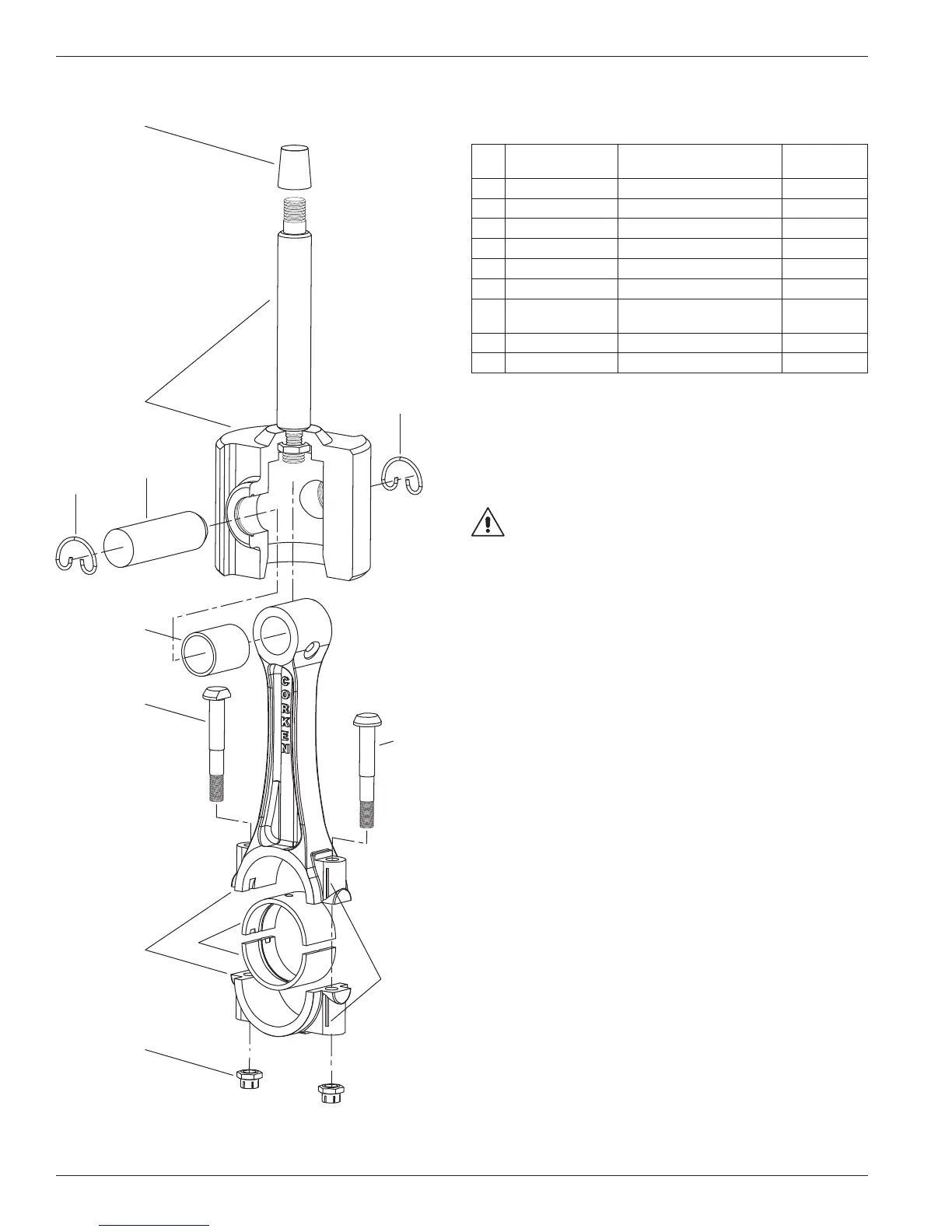

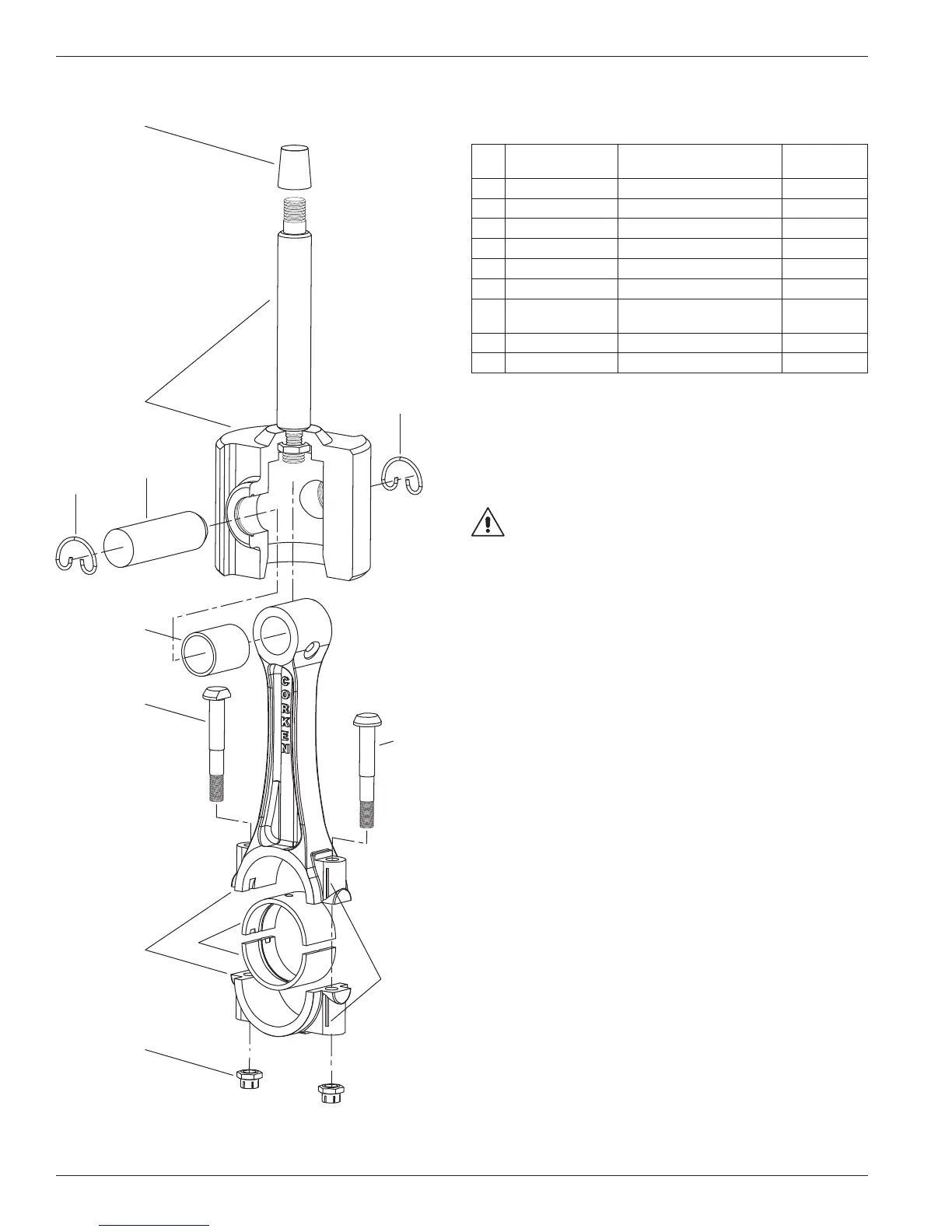

Appendix E—Parts Details for 291 and F291 Connecting Rod Assembly

Connecting Rod—Bill of Materials

Ref

No.

Part No. Description

Qty. per

Compressor

1. 1132-X 2 Crosshead assembly 2

2. 1498 Retainer ring 4

3. 2505 Wrist pin 2

4. 1846-X

a, b

Wrist pin bushing 2

5. 1599

b

Bolt 4

6. 1889-X Connecting rod assembly 2

7. 1367

b

Connecting rod bearing

(pair)

2

8. 1600

b, c

Nut 4

9. 4005 Packing installation cone 1

a

After the wrist pin bushing has been pressed into the connecting rod, it

must be honed to .8759/.8756. A hydraulic press and honing machine are

recommended for this step.

b

Included with connecting rod assembly.

c

Torque connecting rod nut to 28 ft. lbs.

Never attempt to separate the piston rod and crosshead. When repair

becomes necessary, the entire crosshead assembly must be replaced.

WARNING

CAUTION: Always relieve pressure in the unit before attempting

any repairs.

70

Loading...

Loading...