ABS 2.0 Operator’s Manual

Publication Number: 621058590OPR - 54 - © 2019, Cornelius Inc.

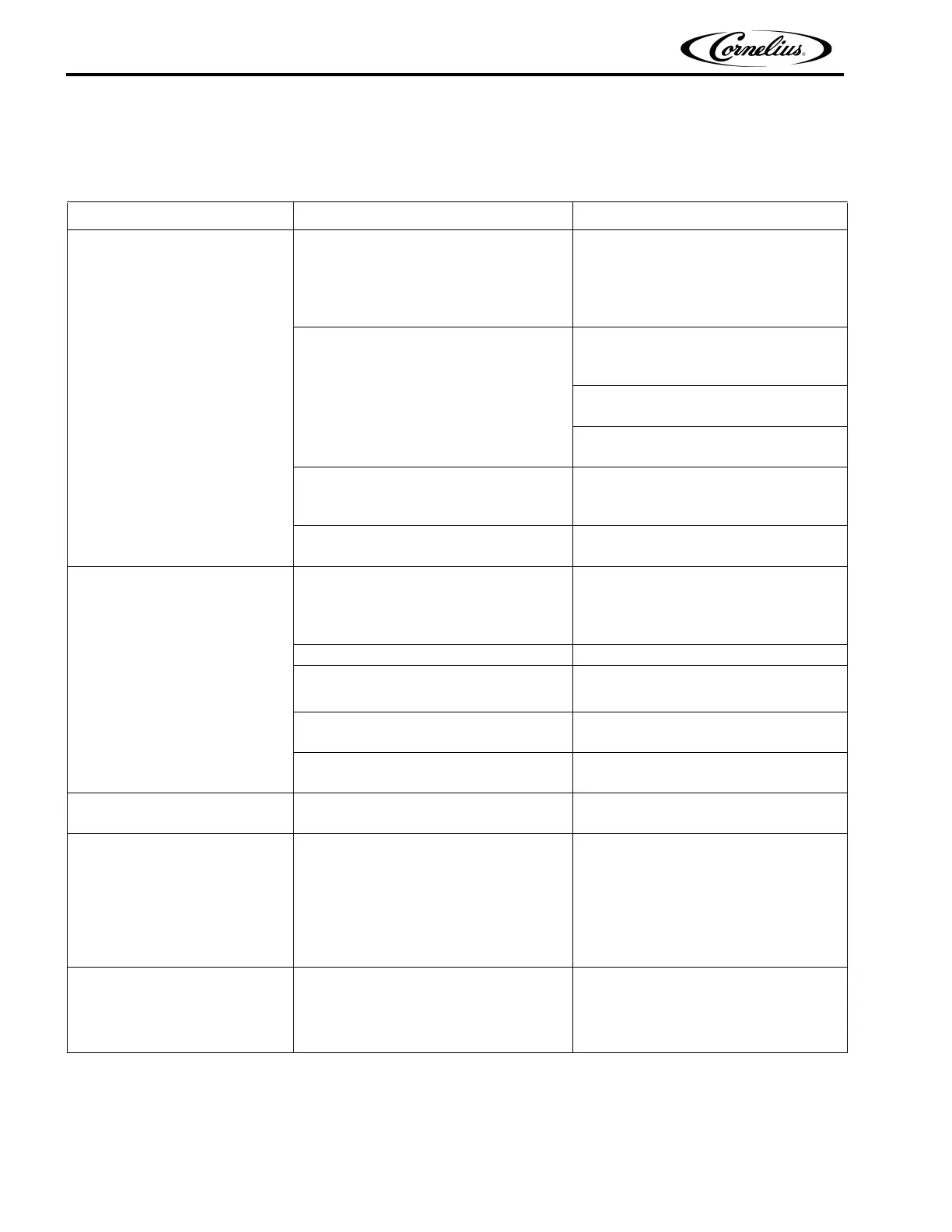

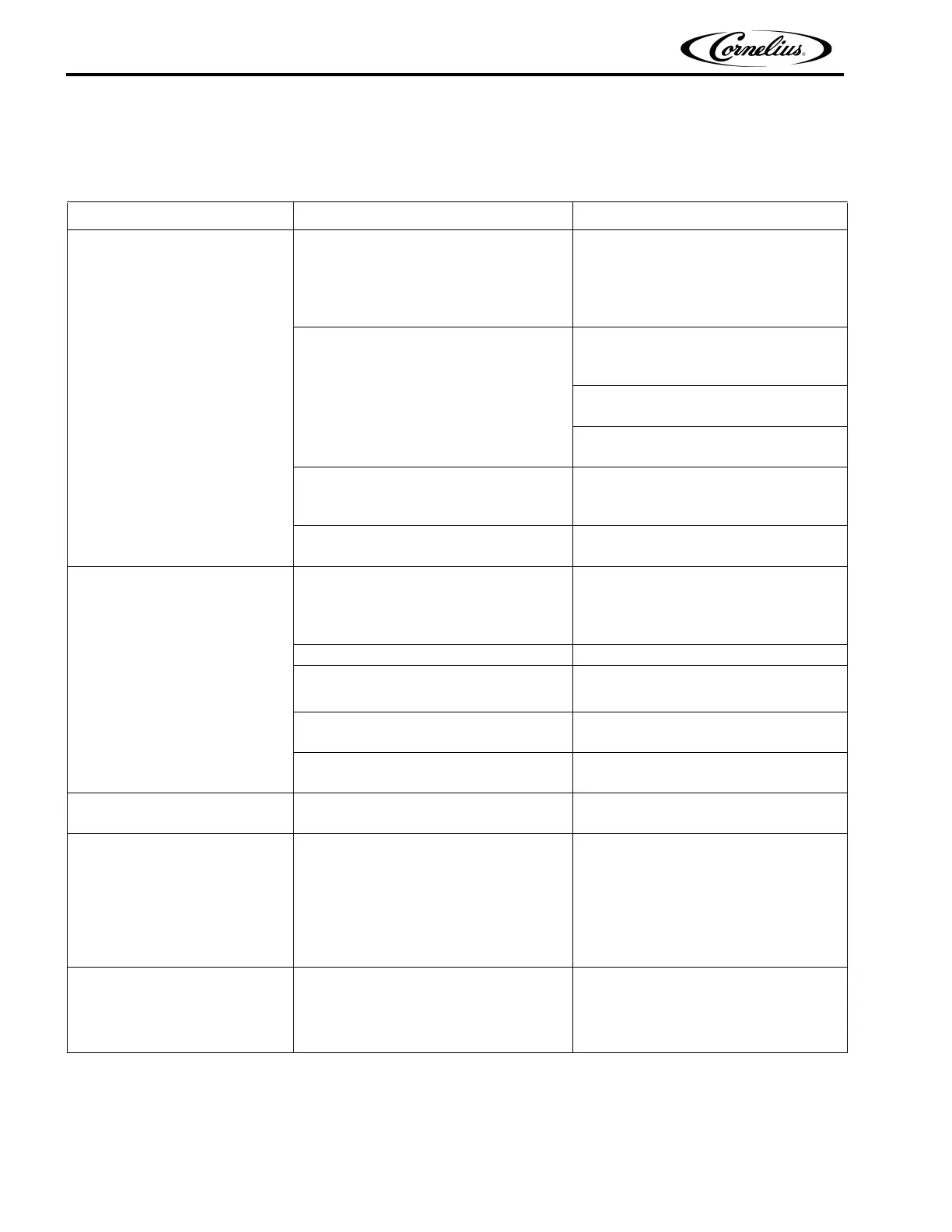

TROUBLESHOOTING

MECHANICAL ISSUES

Table 35

Message Explanation Correction

CLEAR CUP JAM

Cup(s) is jammed in the conveyor at

th

e cup extraction position and the

conveyor and turret are unable to

operate.

Remove all cups from the conveyor

cu

p holders at the Extract Position

before pressing the ENTER button.

Another cup will be extracted and

dispensing will continue.

Cup Tubes.

Over stacking of cups in cup tubes.

DO not fill above the top of the cup

tu

be.

Cup tube fingers are damaged

(

bent), replace all four fingers.

Cup tubes not properly mounted.

Rem

ove and remount cup tubes.

Loose or missing Hardware.

Check each cup tube to

insure all

hardware is present on the cup tube.

Replace any missing hardware.

Cups.

Cups are packed together and will

no

t separate.

NO CUP EXTRACTED

The gripper did not or could not

e

xtract a cup from the cup tube.

Check cup supply at the extract

st

ation and make sure the cups are

not stuck. Make sure the gripper

pads are not damaged

Grabber Pads. Wet, dry off if damaged, replace.

CO

2

Check bulk co

2

tank, if empty go to

back up co

2

and turn on.

Cup Tubes.

Cup tube fingers are damaged

(

bent), replace all four fingers.

Cups

Cups are packed together and will

no

t separate.

TURRET STALLED

Turret unable to rotate clockwise of

counter-clockwis

e.

Clear obstruction (cup holder, cup

tube or cup). Press ENTER

CONVEYOR STALLED

Cup(s) is jammed in the conveyor at

th

e cup extraction position and the

conveyor and turret are unable to

operate.Does the conveyor rotate?

Remove all cups from the conveyor

cup

holders at the EXTRACT

POSITION before pressing the

ENTER button. Another cup will be

extracted and dispensing will

continue.Make sure conveyor is

installed correctly. Repair or Replace.

AIR OR CO

2

LOW OR OUT

CO

2

supply is low or empty or Air

compressor not operating

Change CO

2

cylinder or have bulk tank

refilled.

Check cause not operating and

repair.

.

Loading...

Loading...