Chapter 2: Specifications 13

99-04-23

Gripper

An A255 robot requires the attachment of a gripper (or other end effector) to

perform its intended task. Custom-designed grippers and other end effectors are

available from CRS. Refer to page 57 for gripper installation instructions.

Standard Grippers

Servo Gripper (SGRIP)

An electric servo-controlled, parallel motion, two-finger gripper, capable of

measuring objects between its fingers. Finger travel is 2.0 in. [50.8 mm] with

programmable position and force.

Servo Gripper with Microplate Fingers (SEC-B0-645)

An electric servo-controlled, parallel motion, two-finger gripper, with fingers

specially designed for handling laboratory microplates. Finger travel is 2.0 in. [50.8

mm] with programmable position and force.

Pneumatic Gripper (PGR112/3)

A two-jaw, double acting, air gripper with 3 in. [76.2 mm] long, angular motion, re-

toolable fingers. Fingers can be machined to meet specific needs. Travel is 0–10

degrees per finger.

Grippers (other than CRS)

Grippers must be designed and constructed, so that:

• Power failure does not cause the release of the load, or result in a hazardous

condition.

• Static and dynamic forces exerted by the load and the gripper together are

within the load capacity and dynamic response of the robot.

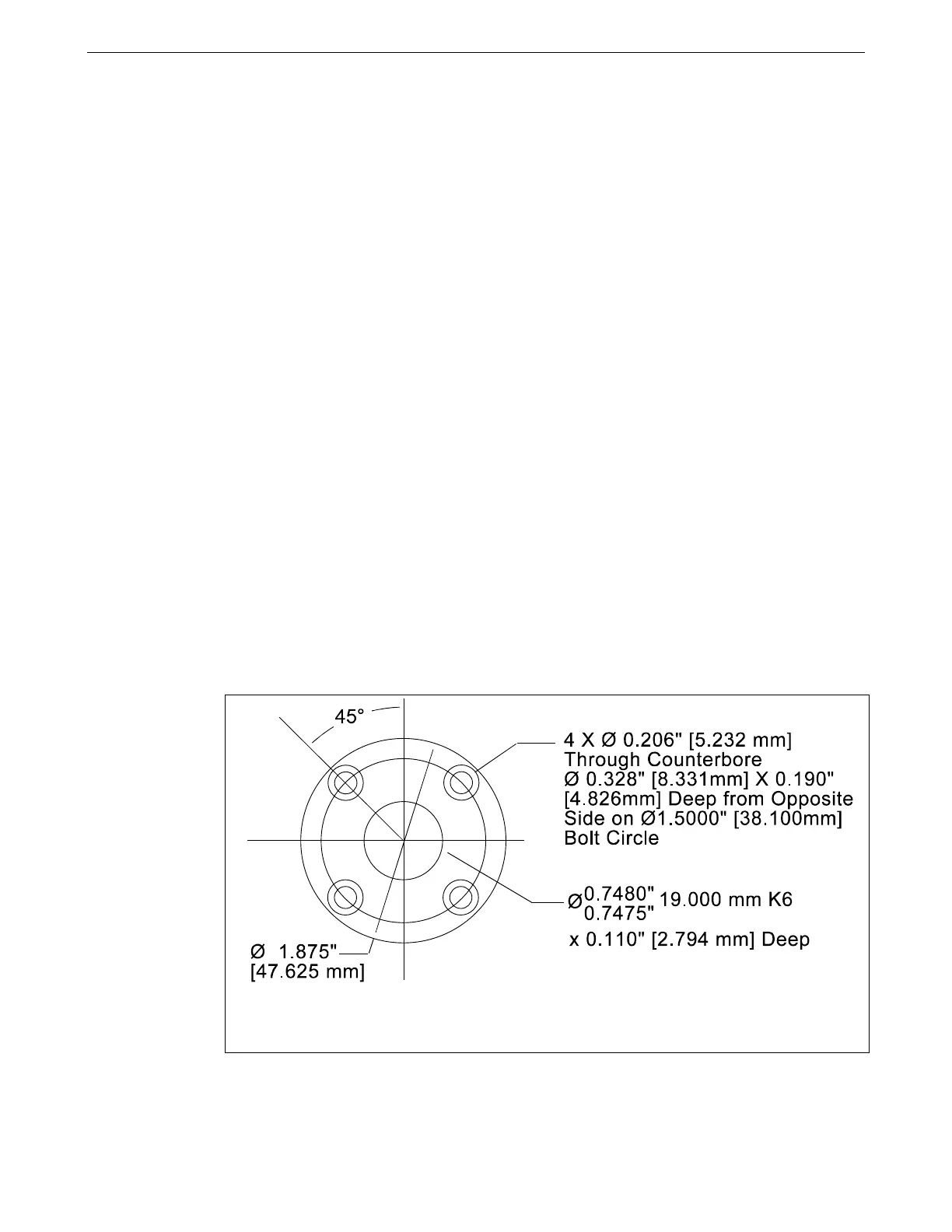

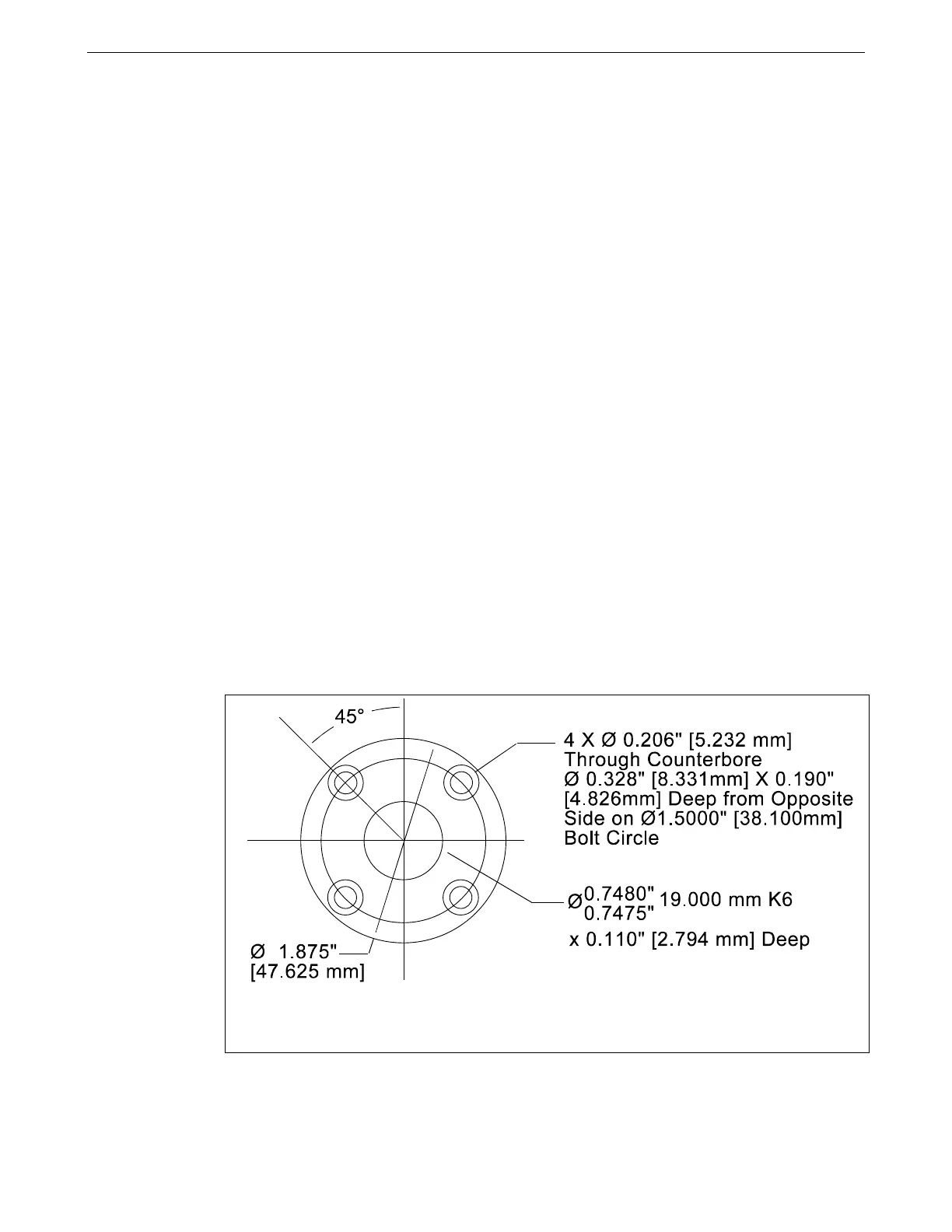

Mounting dimensions of the tool flange for the gripper in inches [mm].

Loading...

Loading...