Installation

VA 500 Bi-directional English 1.24 Seite 12 von 56

7.4 Installation of the Sensor

7.4.1 Mounting VA 500 onto the ball valve

• Assembly is carried out by inserting the connection thread with gasket. (G1/2“

thread, SW 32) into the ball valve with ½"internal thread.

The sensor has be tighten by hand as far as possible and then tighten with

stipulated torque of 25-30 Nm.

It must be ensured that the installation is pressure-tight.

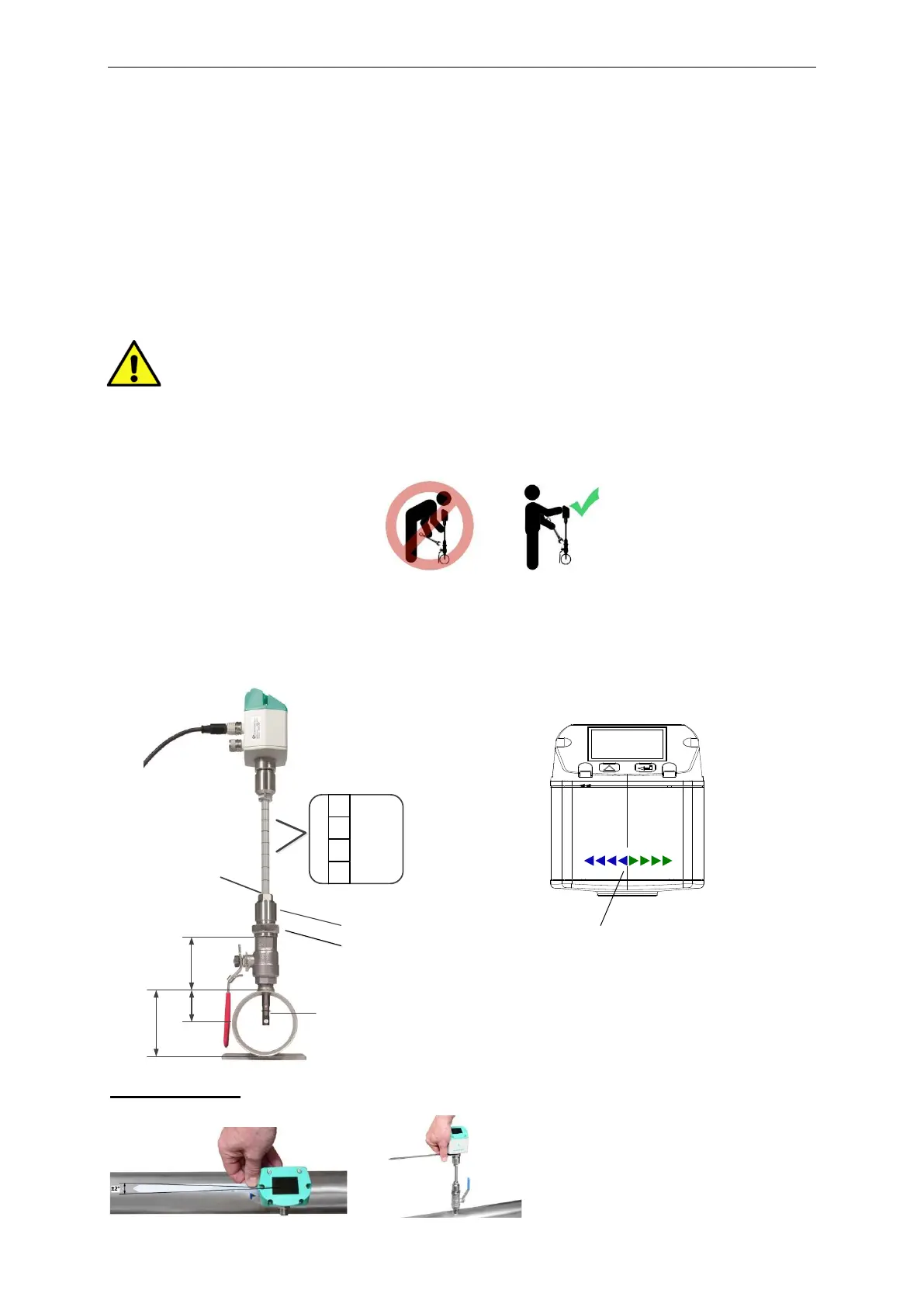

• The sensor is then inserted to the required immersion depth (sensor tip in the

middle of pipe) and aligned according to the direction of the airflow.

A depth scale engraved on the probe tube, a flow alignment arrow and an

aligning device will be of help for you.

Once the sensor has been aligned the adapter sleeve must be tighten

with stipulated torque of 20-30Nm (SW 17).

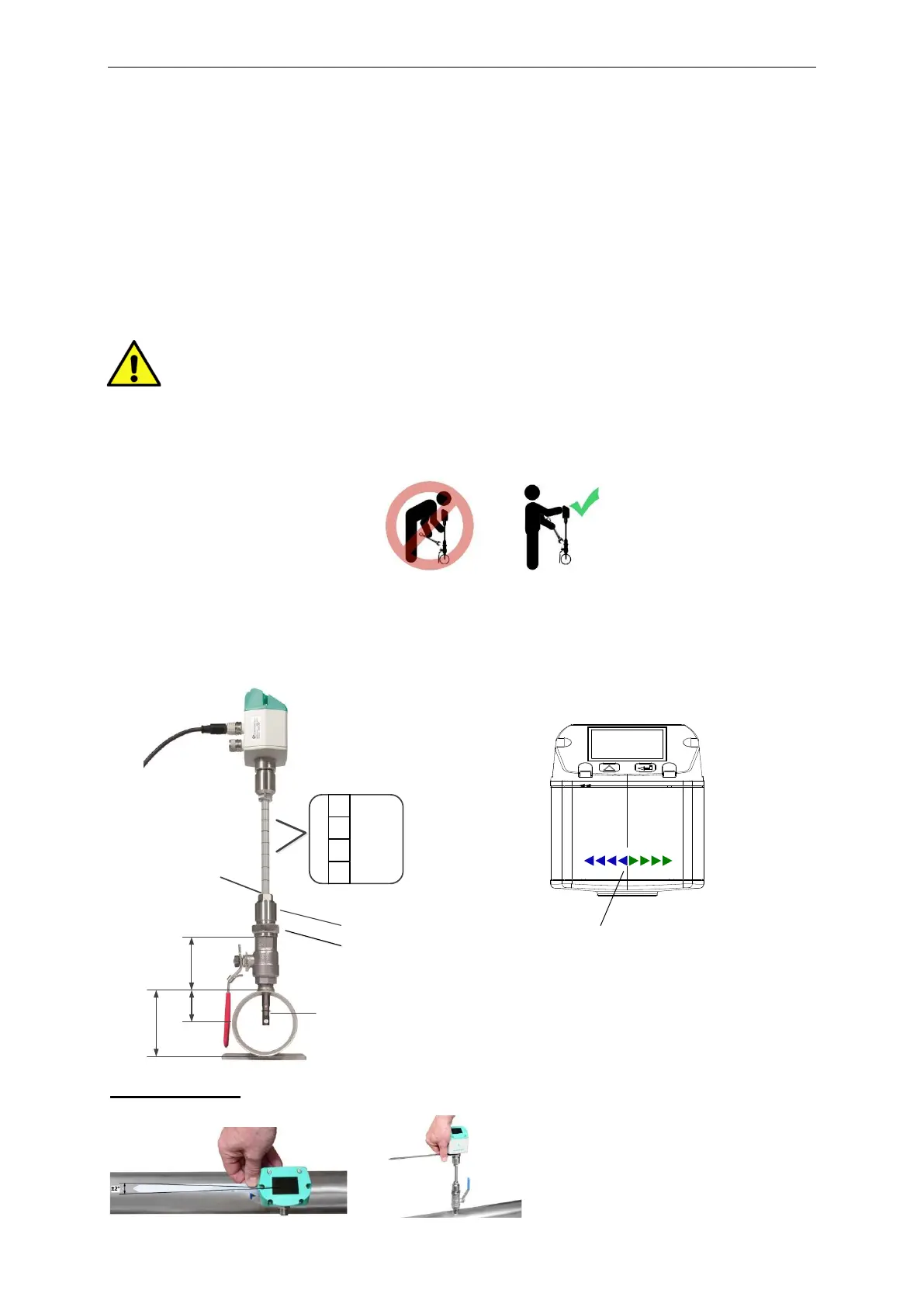

WARNING

Components under high pressure! Risk of injury if the flow sensor

is not installed in a pressure-tight manner.

After installation, be sure to check and ensure the pressure tightness

of the connection. Do not work directly over the sensor, but next to it to

minimise possible hazards.

Attention: Alignment of the sensor must not be modified when tightening the connection thread and

adapter sleeve. In this case, please check the immersion depth and alignment again and

correct it if necessary. The angular deviation should not be greater than 2° in relation to

ideal position as otherwise the measuring accuracy will decrease.

Calculation mounting depth: Alignment flow direction

Loading...

Loading...