57

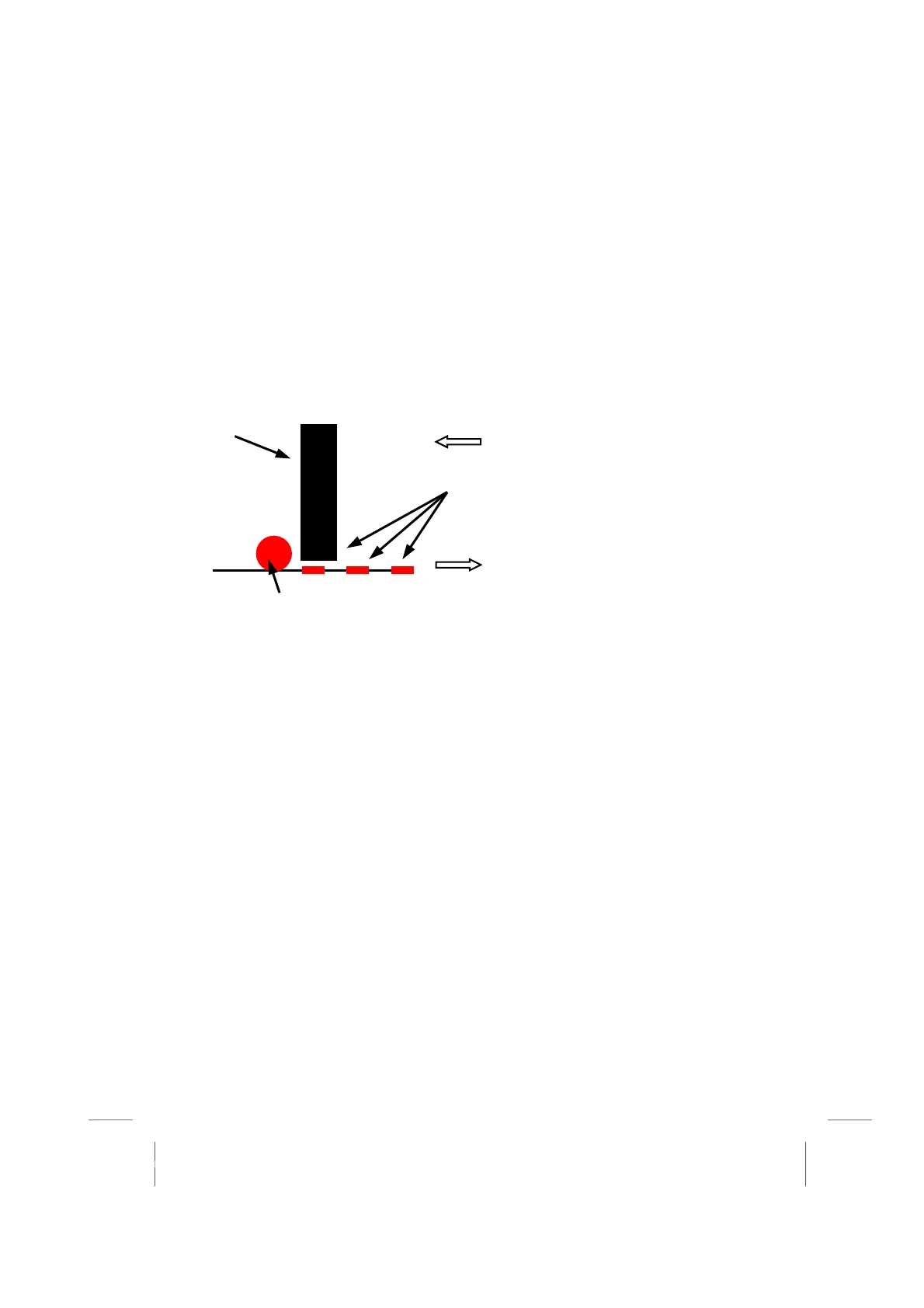

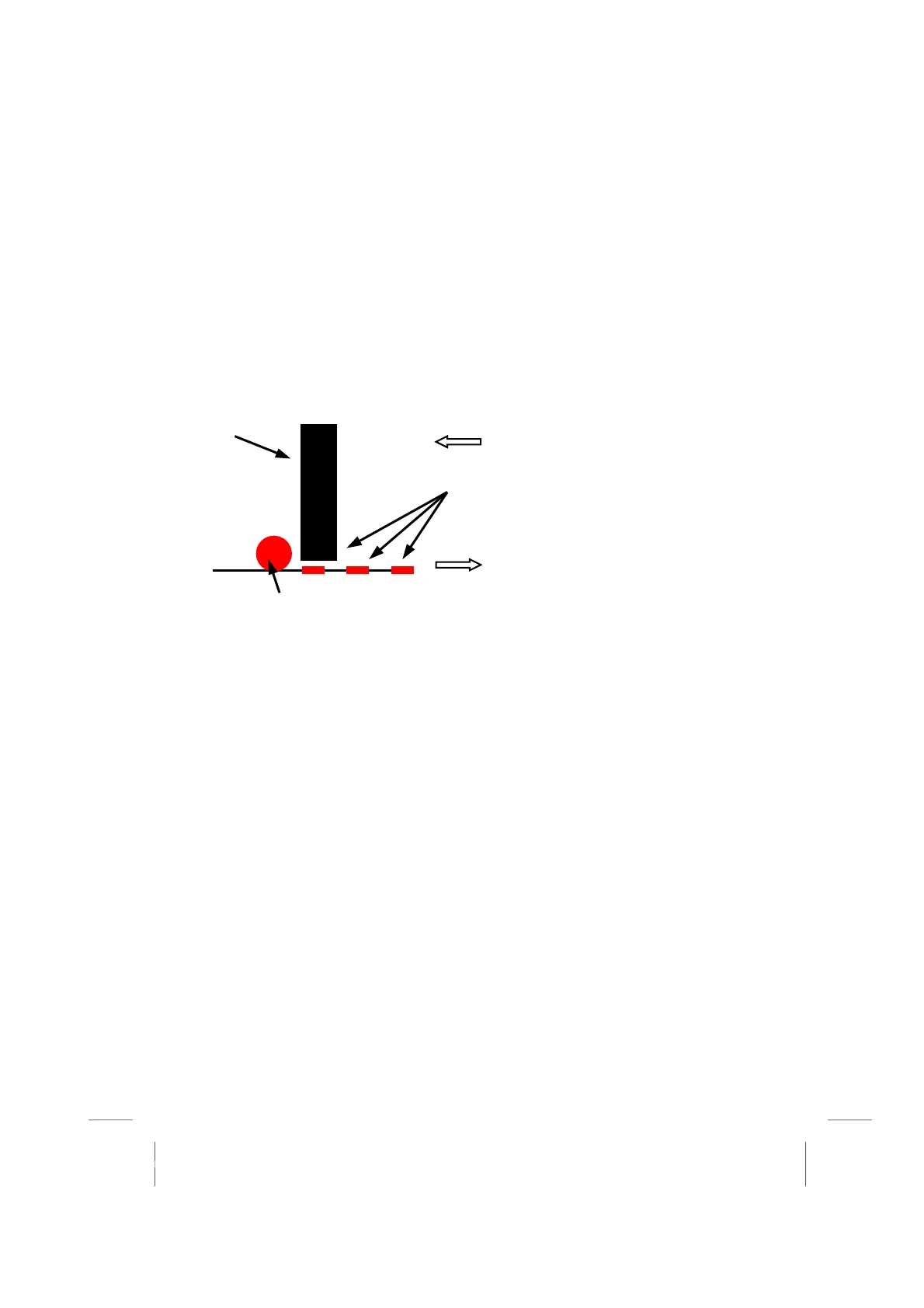

7.7 HIGH SPEED SHEAR TESTS BALL ALLIGNMENT

High-speed shear tests are performed using the same work holder as used for the ball clearance.

During high speed testing it is very important to ensure that the ceramic tip will not hit anything

during a test. This can be caused by poor ball clearance, incorrect fixturing or the shear height

being to low for the sample being tested.

Note: The lower the speed set for the shear tests the shorter the distance allowed for

acceleration prior to the actual test.

The alignment of a high-speed test is very similar to that described in section 6.5. The row of

balls to be tested must be up against the front of the shear work holder. Once the test is started

the sample will move to the front of the machine to allow for acceleration. As previously

mention this distance varies depending on the test speed set. Once this distance has been

travelled the sample will then move to the rear of the machine at the set test speed.

Note: The ceramic shear tool on the BS5KgHS can be removed very easily however if it is

removed then the load cell will require a re-calibration.

Ball to be tested

Ceramic Tip

Balls removed during ball clearance

Sample move towards the front of the

machine to allow for acceleration.

Sample will move to the rear of the machine so

that the test can occur at the set s

eed.

Loading...

Loading...