58

7.8 ZONE SHEAR TESTING USING THE ZONE SHEAR TABLE

As mentioned in the previous section Zone shear testing can only be performed

using the designated zone shear table and the 80Kg-work holder.

The test is set up in the same manner as a high speed shear test and as always care

must be taken to ensure that no collisions can occur.

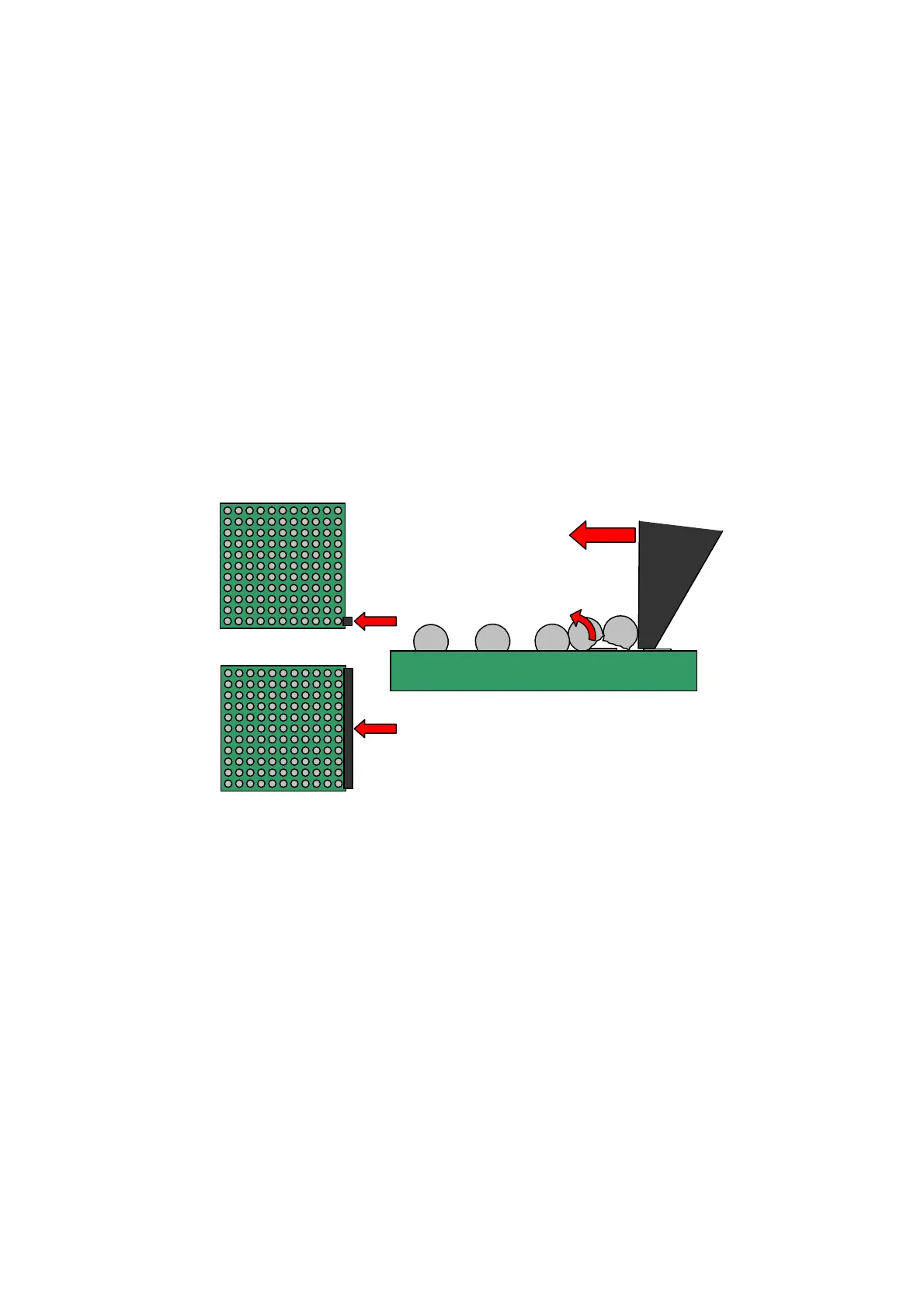

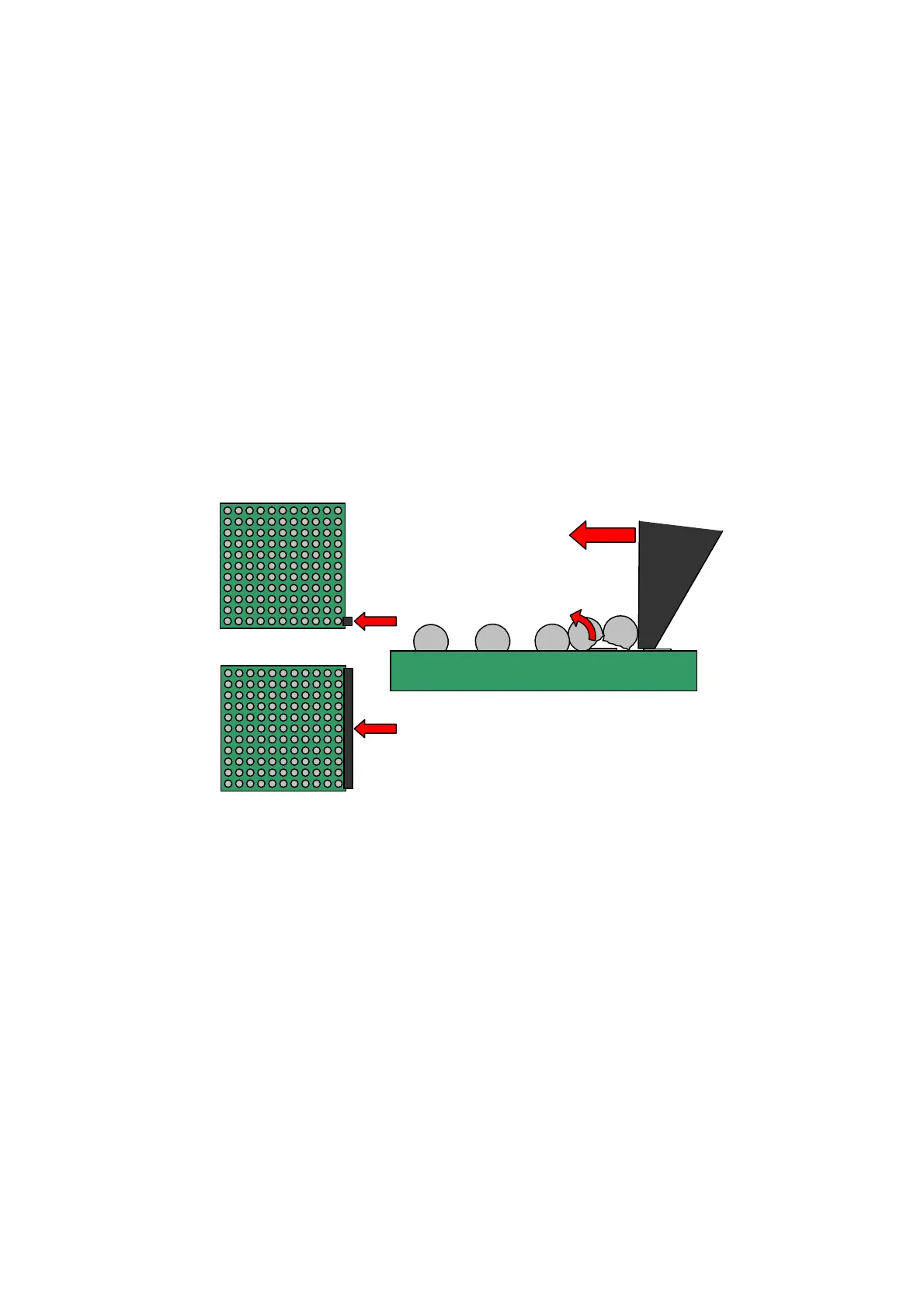

An alternative method to high speed testing zone shear is when many solder balls

are sheared in one pass of a shear tool. Either one row or many rows can be

sheared in one pass as shown below. This can be done at high speed, typically

600mm/s, or at relatively lower speeds such as 5mm/s. In this test balls are

mostly sheared by a ball or balls being driven by the shear tool. Consequently the

loading conditions such as shear height and load direction on each ball is

different and cannot be predicted. Because of this force data has limited value and

failure mode is used to qualify bond integrity.

Samples are inspected after shear. The percentage of bond failure area Vs solder

shear area is used to assess bond strength. Individual bonds are often a mixture of

some solder shear and some bond failure, the percentage of each bond is assessed

to the nearest 10% and added to the averaged total for the sample. Good bonds

will be predominantly solder shear. Bad bonds will typically result in an area of

25% bond failure.

The 4000HS-Z Differs from the 4000HS in three key areas mostly related to the

larger XY table. This requires the guards to be bigger which leads to the

requirement of a stretched keyboard rest. One of the side panels is bulged to

accommodate the larger motor assembly. Despite these changes the functionality

of the machine is essentially the same as the 4000HS.

Shear one row

Shear multiple rows

Figure 4.

Peeling action

Loading...

Loading...