●Troubleshooting

79

Troubleshooting

7

Troubleshooting

Troubleshooting According to Symptoms

1

If an operation shows an abnormality even though no alarm code is displayed, refer to the following information to take measures.

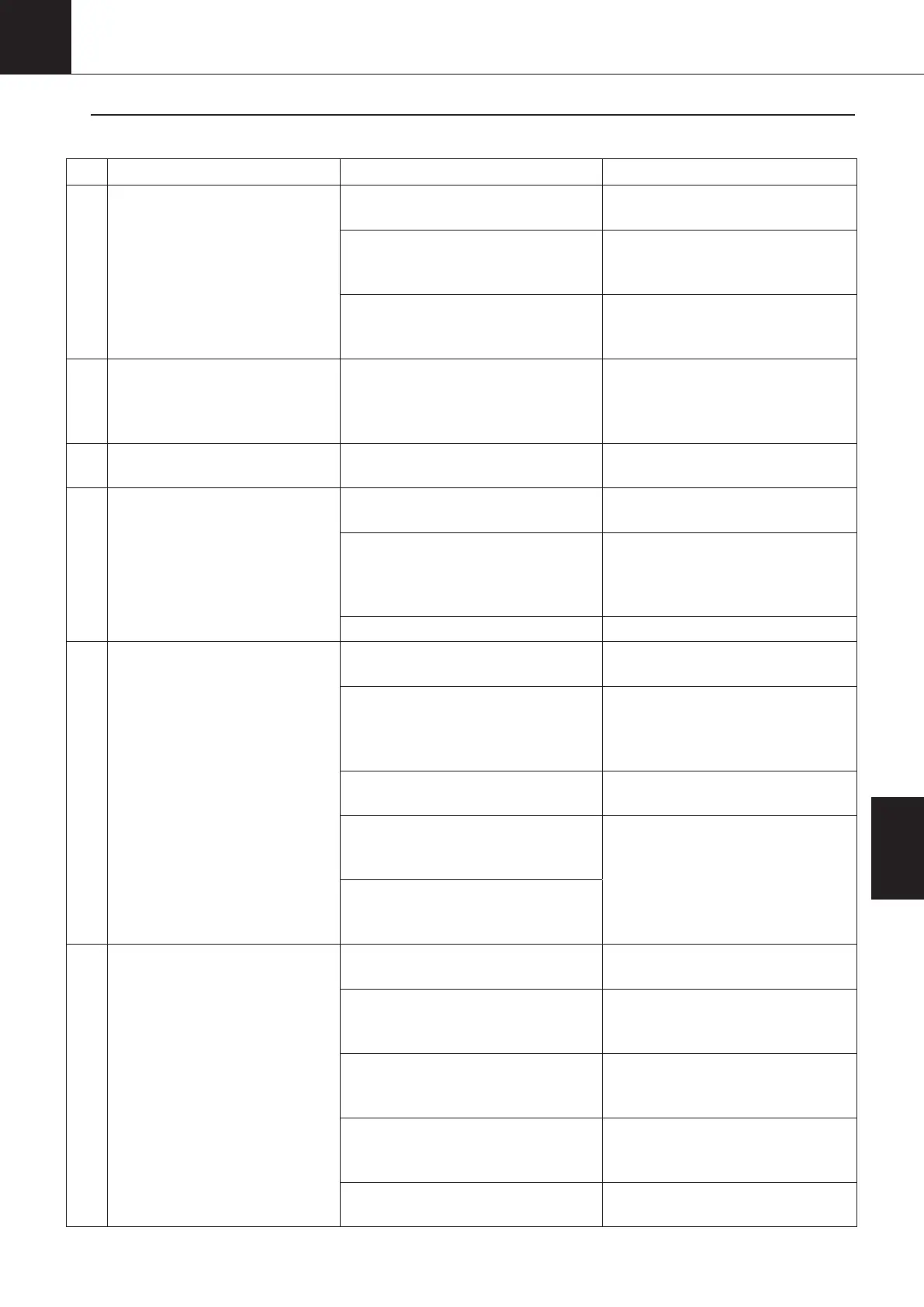

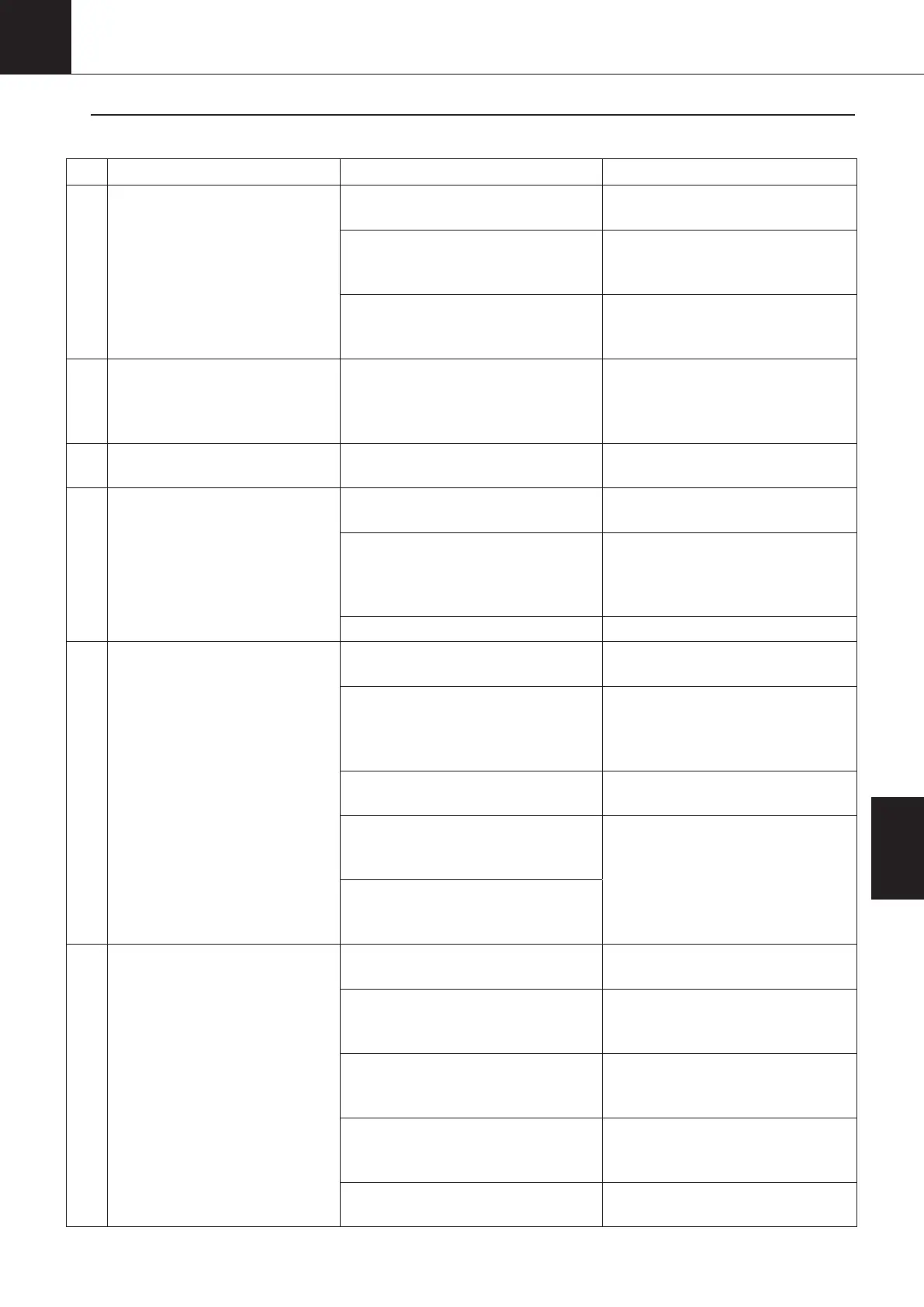

Item Condition Cause Measure

1

The unit does not run at all.

(The POWER lamp on the control

panel is unlit.)

(1) The main power supply is OFF.

Check that power is supplied to the

power supply terminal.

(2)

(for models with a breaker)

The electric component breaker has

tripped.

Or, it has not been turned ON.

Open the switch box cover and check

if the breaker has tripped.

(3) The wiring that supplies power to

the control board is disconnected or

broken.

Check the wiring between the control

board and the inverter board.

2

The control panel displays “ACF”

and then turns off.

(1) The main power supply is OFF.

This is the normal operation when the

main power supply is OFF. Check that

power is supplied to the power supply

terminal.

3

The pump/fan is operating, but the

control panel is unlit.

(1) The wiring for the control panel is

disconnected or broken.

Check the wiring between the control

board and the control panel.

4 Pump/fan does not run.

(1) The remote control input ([10]–[11])

is OFF.

Check the connection of the remote

control input.

(2)

The unit has been set to the

operation lock mode.

(With the factory setting, the

operation Loc

k mode is selected.)

Cancel the operation Lock mode on

the control panel.

(See page 60.)

(3) The pump wiring is disconnected. Check the pump wiring.

5

Oil does not flow, although the

pump is running.

Because the oil circulation

quantity is insufficient,

the pump sound level is large.

(1) The pump suction pipe connection

is loose.

Check the seal of the pipe and

retighten.

(2) The suction strainer is clogged.

Clean the suction strainer.

If the oil in the oil tank is dirty, replace

the oil.

(See page 161.)

(3) The oil level in the oil tank has

decreased.

Refill oil into the oil tank.

(4)

Because of a large pressure loss

in the oil discharge pipe, the pump

relief valve is activated.

Increase the oil pipe diameter, and

shorten the pipe length.

Check that the oil viscosity is within

the specified operating range.

(5)

Because of a large pressure loss in

the oil suction pipe, cavitation has

occurred with the pump.

6

The compressor does not run,

although the pump is running.

(1)

The compressor is stopped under

temperature control.

– – –

(2) The compressor restart prevention

timer has been activated.

Check if the compressor starts after

elapse of the timer time (about 2

minutes).

(3)

The low oil temperature protection

device has been activated. (Inlet oil

temperature is 2℃ or lower.)

Check if the compressor normally

operates at 5℃ or higher oil

temperature.

(4)

The low ambient temperature

protection device has been activated.

(Room temperature is –2℃ or lower.)

Check if the compressor normally

operates at 0℃ or higher room

temperature.

(5) The capacity setting is 0%

(Operation mode 9).

Operate in an operation mode

appropriate for use.

00_PB00540A_M10.indb 79 2023/08/09 12:59:04

Loading...

Loading...