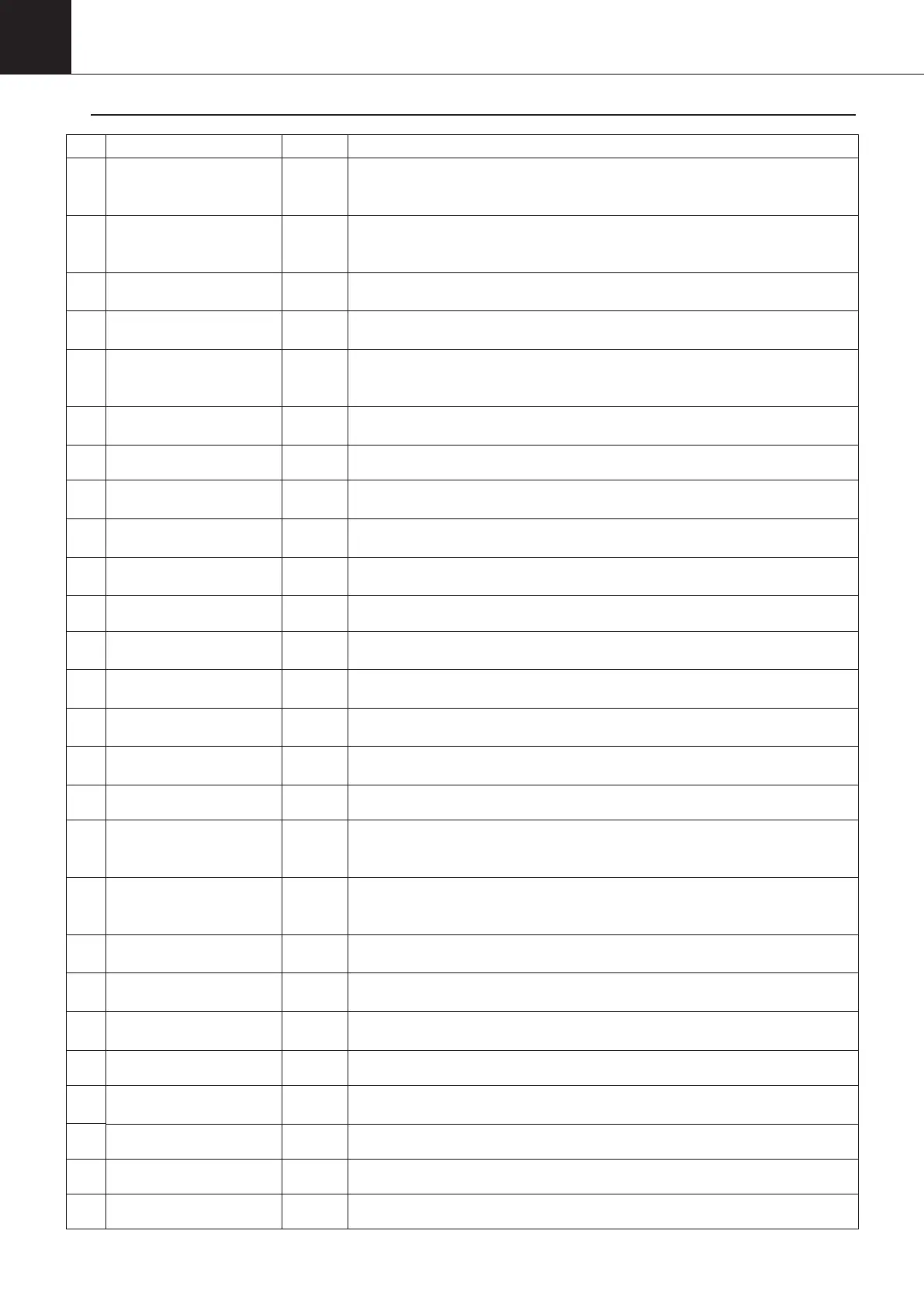

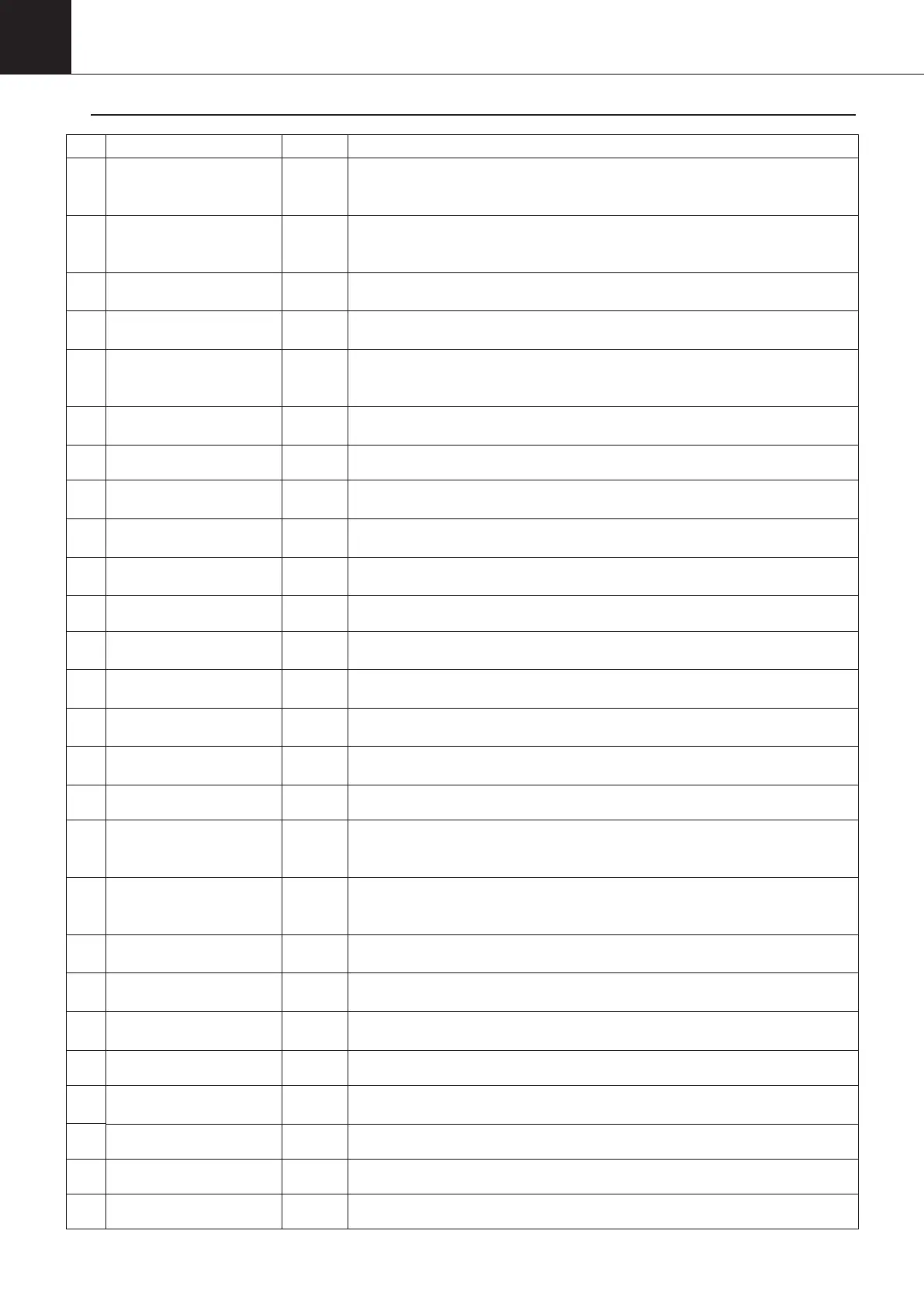

4

Piping Diagrams

52

No. Part Name

Symbol

Function

① Compressor M2C

This compressor is a swing compressor with a built-in DC motor. The

compressor is driven under the inverter control by changing the operating

frequency according to values specified under the capacity control.

② Accumulator -

The accumulator is installed before the compressor suction and used

to prevent the entry of liquid refrigerant in the compressor and further

efficiently return lubricating oil to the compressor.

③ Condenser -

Used to air-cool the refrigerant to turn it from high-temperature and

-pressure gaseous state to high-temperature and -pressure liquid state.

④ Fan M3F

The feedback control of fan revolutions is performed for heat exchange

through the condenser.

⑤ Evaporator -

Used to heat low-temperature, low-pressure liquid refrigerant

decompressed through the electronic expansion valve (with oil being

cooled) to make it low-temperature, low-pressure gas.

⑥ Rubber hose -

Located at the entrance to and the exit of the oil pump and used to prevent the

vibrations of the oil pump from transmitting to the piping system and equipment.

⑦ Oil pump M1P Used to circulate oil.

⑧ Relief valve -

The relief valve is a protective device to be activated when the pressure of oil piping system

reaches the specified level or higher, thus setting the pressure back to the normal level.

⑨

Electronic expansion valve

for main circuit (EEV)

Y1E

The valve varies its opening according to values specified under the

capacity control, thus making the control of refrigerant recirculation quantity.

⑩

Motor operated valve

for hot gas (MOV)

Y2E

This valve controls cooling capacity under low load by bypassing

refrigerant from the high pressure side to the low one.

⑪ Filter -

Used to prevent the entry of foreign matters in the valves (for both valves).

⑫

Compressor protection

thermostat

S2T

When the compressor body exceeds a temperature of 125℃, used to

display the alarm code “E5”, thus stopping the system due to malfunction.

⑬

Machine body thermistor

(optional)

Th-1

Used to detect the synchronization source temperature while in

temperature tuning control mode.

⑭ Outlet oil thermistor Th-2

Used to detect the oil outlet temperature (targeted control temperature)

from the evaporator.

⑮ Room thermistor Th-3

Used to detect the synchronization source temperature while in

temperature tuning control mode.

⑯ Inlet oil thermistor Th-4

Used to detect the oil inlet temperature (targeted control temperature) to the evaporator.

⑰ Discharge thermistor Th-6

Used to detect the discharge pipe temperature and, when the discharge

pipe temperature exceeds 115℃, thus displaying the malfunction code

“E5” to stop the system due to malfunction.

⑱ Condenser thermistor Th-7

Used to detect the condensing temperature and, when the condenser

temperature exceeds 62℃, thus displaying the malfunction code “E3” to

stop the system due to malfunction.

⑲

Electronic expansion

valve outlet thermistor

Th-8

While in zero point adjustment, used to detect variations in the electronic

expansion valve outlet temperature, thus recognizing the Fully Closed point.

⑳

Returned oil thermistor

(optional)

Th-9 Detect the oil temperature of the main engine oil pipe (returned pipe).

Oil drain (evaporator) -

Closed by plug Rc1/4. (The evaporator oil can be discharged from this oil

drain for maintenance.)

Oil drain (drain pan) - Used to drain oil from the bottom of the oil cooling unit.

Oil tank -

Used to store oil at all times, thus responding to a sharp fluctuation in oil

quantity in the piping system.

Oil charge port & Air breather

-

Used to fill oil into the oil tank and normally serve as a ventilation hole for the oil tank.

Oil level indicator - Used to indicate oil quantity in the oil tank.

Low-pressure gauge port

- Used to mount a gauge for maintenance.

*For the layout of parts, refer to information on pages 56 and 57.

AKZ56A/90A-T, AKZ56A/90AT500

6

00_PB00540A_M10.indb 52 2023/08/09 12:58:58

Loading...

Loading...