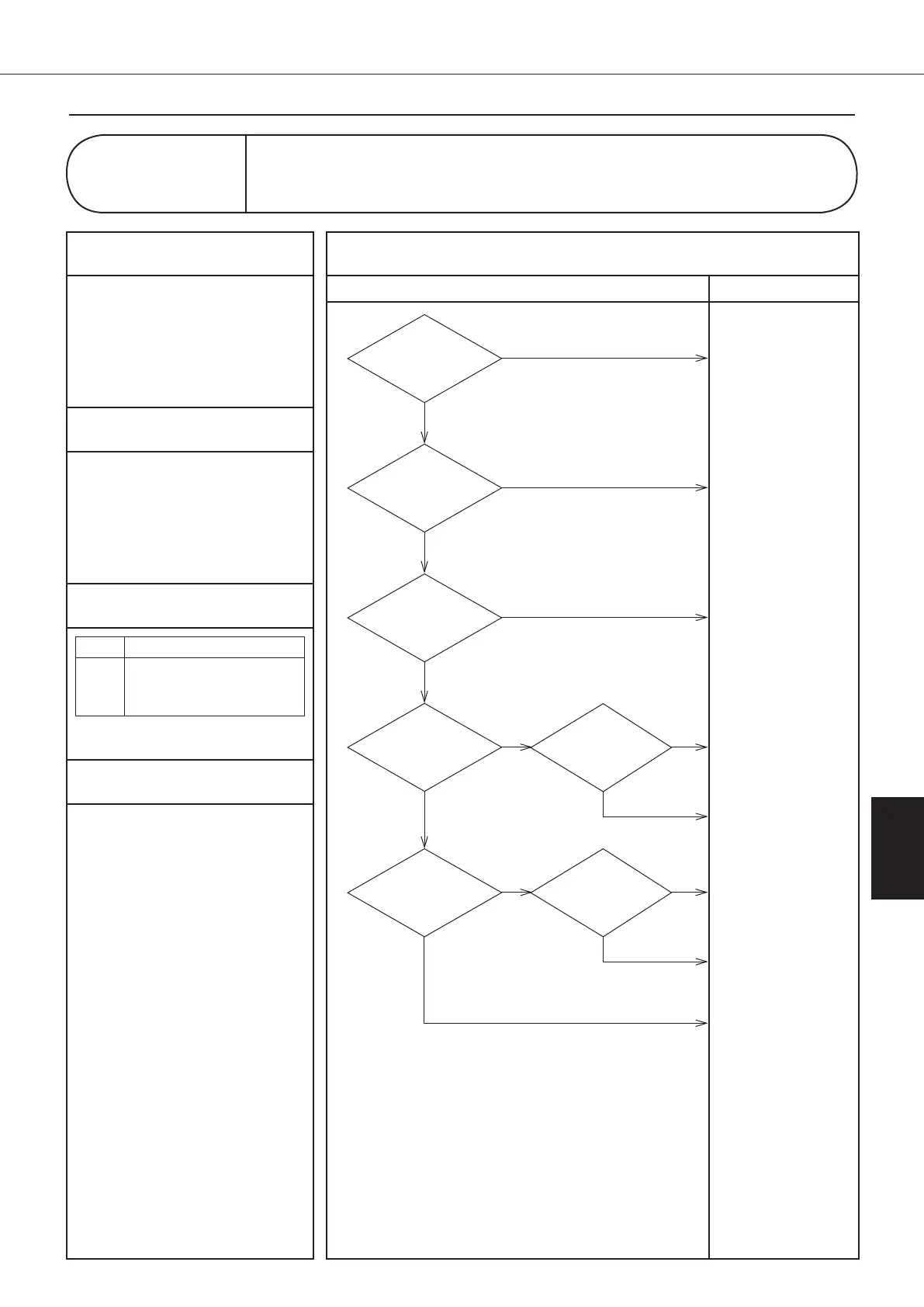

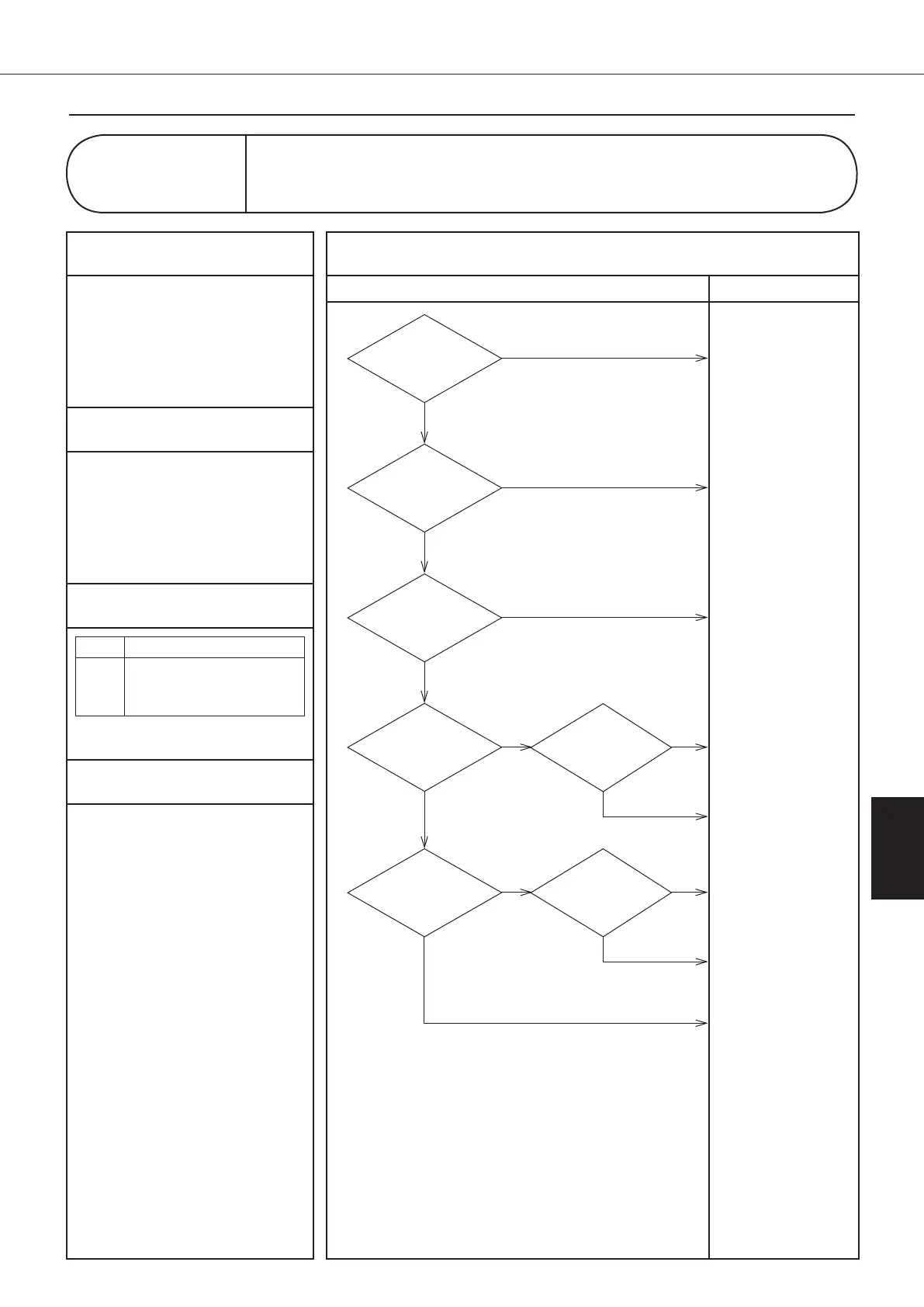

●Troubleshooting

95

7

Troubleshooting

Troubleshooting

5

Troubleshooting

Diagnosis Countermeasures

1

Applicable Models

AKZ**A (All series)

2

Methods of Malfunction Detection

Detect with the pump motor

overcurrent relay (K1S).

3

Malfunction Decision Conditions

Class Conditions

50

When the pump motor

over current relay is

actuated.

4

Supposed Causes

1Defective oil piping by

customer

1Faulty oil pump (M1P)

1Incompatible viscosity of oil

used

1Faulty pump motor over

current relay (K1S)

1Faulty control board (A1P)

Control panel display

EH

Actuation of Pump Overcurrent Relay

Correct the power

supply voltage.

NO

Does

the power supply

voltage fall within the

range of rating

±10%?

YES

Change the oil to one

with viscosity of VG32 or

less.

NO

Connect to S182.

YES

NO

NO

Is there

conduction of

connector

S182?

YES

Replace the oil pump

(M1P).

(See page 127/142)

YES

Piping

pressure loss

on the main machine side

exceeds

0.5 MPa.

YES

The

viscosity of

oil used is in excess

of

VG32.

Improve the piping.

(Contact the customer.)

NO

Replace the over

current relay (K1S) or

harness.

YES

Is the

overcurrent relay

faulty or is the harness to

connector S182

derailed?

NO

Is connector S182

disconnected?

Connect the pump

power supply terminal

properly.

NO

YES

Pump

power supply

terminal is properly

connected to the

board.

Replace the control

board (A1P).

(See page 122/137)

00_PB00540A_M10.indb 95 2023/08/09 12:59:06

Loading...

Loading...