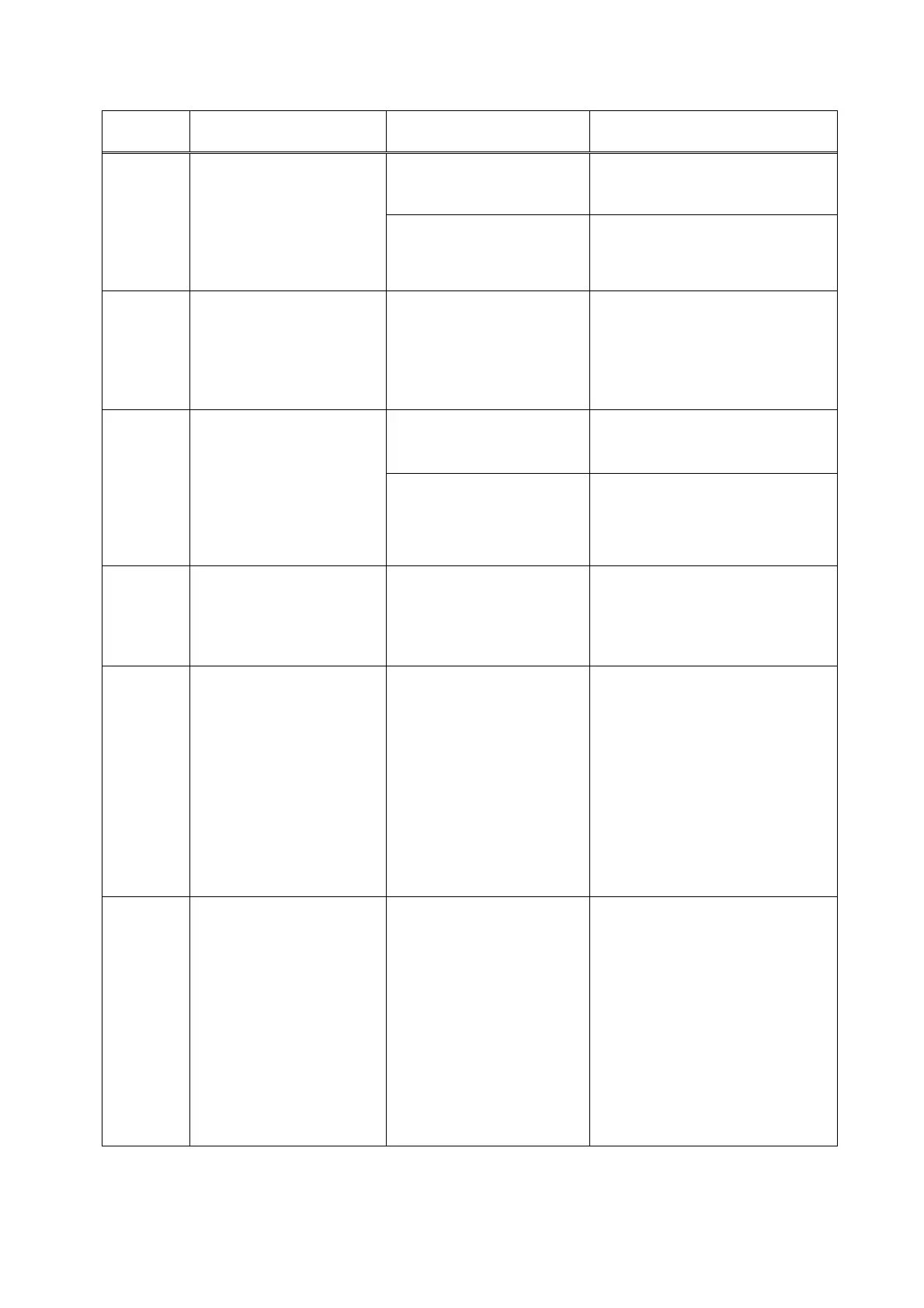

65

PIM00504

Warning

Code

Name Cause Corrective Action

L49

Motor electronic

thermal relay overload

Overload protection

triggered by the electronic

thermal relay has been

actuated.

The load torque is larger

than usual due to wear of

the pump, for example.

Replace the pump or motor

pump.

The motor magnets have

demagnetized and the

current has increased.

Replace the motor or motor

pump.

L50

Power supply voltage

drop

The main circuit voltage

value remained at under

254 V for 2 seconds.

The input power supply

voltage is low.

Improve the power supply

environment.

L53

Controller cooling fan

rotation speed drop

warning

The cooling fan speed

has decreased to 80% or

less of the normal speed

for 10 seconds or longer.

The cooling fan has

stopped.

• Replace the fuse for the fan.

• Replace the cooling fan.

• Replace the controller.

Foreign matter or dirt has

become entrapped in the

cooling fan.

Clean or replace the cooling fan.

L63

Pressure switch

actuation

The pressure switch has

been actuated.

The pressure reached the

value set for parameter

“P01: Pressure switch” or

lower.

If there is nothing abnormal in the

operation of the main machine,

review the set value for the

pressure switch or the delay time.

L67

Holding pressure

rotation speed drop

When target rotational

speed = 300 min

-1

, and

the status where pressure

value ≥ (set value + [H51:

DHSL] L67: Holding

pressure speed drop

warning judgment

pressure offset) has

continued for 2 seconds.

The throttle is clogged.

• Clean the throttle of the high-

pressure safety valve.

• Adjust the throttle.

• Replace the oil.

L70

Reverse rotation

When the start command

goes from OFF to ON and

the pressure does not

reach “H54: RT_O

Reverse rotation warning

judgment pressure” or

higher even after “P48:

T_SP Reverse rotation

warning judgment wait

time” or longer has

elapsed.

A run command has been

input immediately after a

stop while the load was

excessive.

• Increase the value of

parameter P48.

• Review the run timing and

delay the timing for issuing the

start command.

Loading...

Loading...