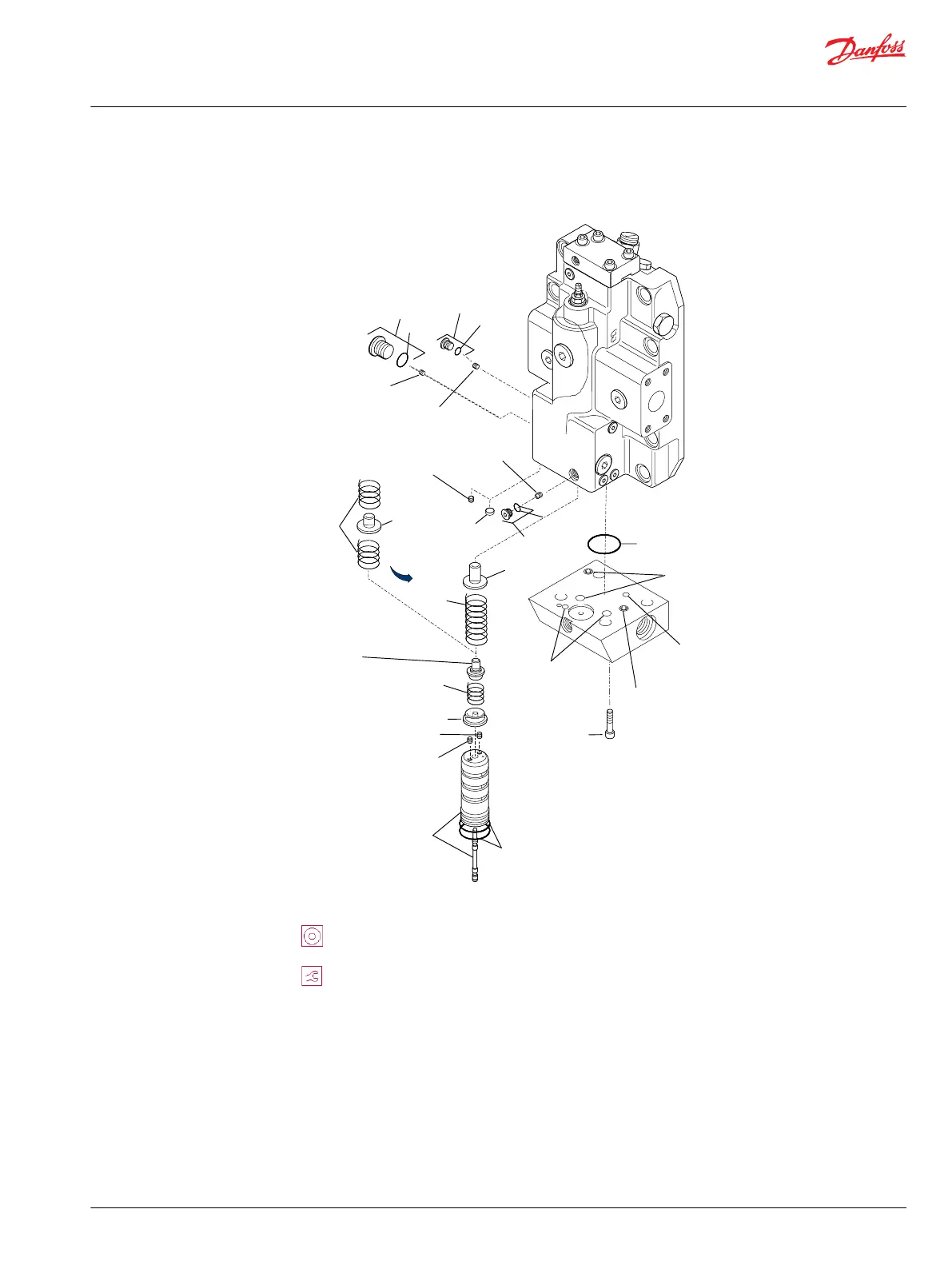

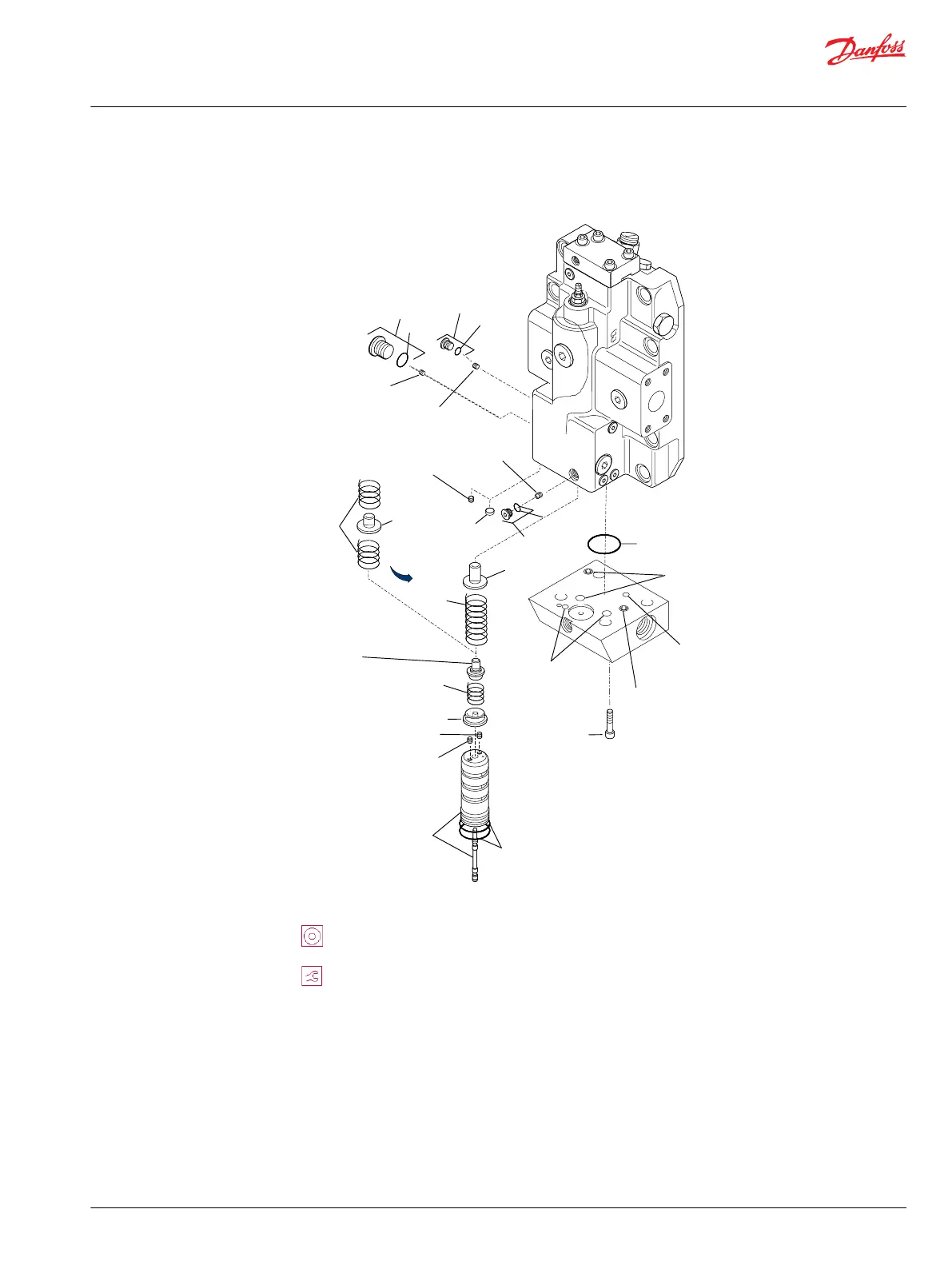

4. Lubricate the sleeve and O-rings with clean hydraulic oil.

Assembly orientation

T3**

T1**

T2**

U5**

G90

S10

S20

S10*

(060, 080

110)

S10*

(160, 250)

J30

J10*

J20/S70

T7**

T8**

F324

F32

G30A

G30

G12

G12A

G30A

G30

G36

G42

G38

G42

G38

M22

P101 240

Legend for T1, T2, T3

use a 3 mm hex wrench for 60 cm³, 80 cm³, 110 cm³, 160 cm³, 250 cm³ motors

4 N•m [2.95 lbf•ft]

5. Push the sleeve (F32) into the cavity.

6. Lubricate the 4-way spool with clean hydraulic oil.

7. Install the 4-way spool in the cavity of the sleeve.

8. Install orifices (T1, T2, and T3) in the appropriate cavities.

9. Torque the (T1, T2, and T3) orifices to 4 N•m [2.95 lbf•ft] using a 3 mm hex wrench.

10. Install new rings (G12A and G30A) on the cavity plugs (G12 and G30).

11. Install the cavity plugs in the orifice cavities.

12. Torque the cavity plugs (G12) to 37 N•m [27 lbf•ft] using a ¼-inch hex wrench.

13. Torque the cavity plugs (G30) to 6 N•m [4 lbf•ft] using a 1/8-inch wrench.

Service Manual

Series 51 and 51-1 Motors

Minor repair

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 59

Loading...

Loading...