Suction Pressure Optimization

The Adaptive Suction Pressure function in your AK-SM makes it

possible to automatically optimize the suction pressure so that it

will be adapted to the systems actual load. During optimization,

data is collected that tells the system which refrigeration

appliances are most heavily loaded. This energy saving function

can make substantial savings directly whilst also saving on

compressor wear and tear and also providing an analysis tool for

refrigeration appliances.

The individual controllers handle the temperature control in

the refrigeration appliances. The load and operating conditions

of each are continuously collected by the AK-SM via the data

communication system. The collected data is computed and the

“most heavily loaded” refrigeration points are identied.

An adaptation can now be made of the Suction Pressure, whilst

ensuring the air temperature at the refrigeration appliance

is maintained. It is the AK-SM that collects data from the

refrigeration appliances and it is the AK-SM that transmits any

oset to the compressor pack control so that suction pressure

reference is changed to suit the needs of the “most heavily loaded”

refrigeration point. It is always the temperature at the appliance

that takes top priority and in fact the suction pressure can oat

down if necessary.

The time during which a refrigeration point has been designated

“the most heavily loaded” will be summed up in the log (history)

within the AK-SM.

The pack suction (Po) pressure is optimized in accordance with

the current refrigeration demand, taking into account short-

term changes (day/night setback/defrost) and long-term eects

(seasonal/weather changes).

In order to get the best eciency out of the Po Optimization

function it is highly recommended that a plant survey is done

before enabling this function. A poorly running site will not

be corrected by Po Optimization and the maximum benets

will not be seen - ensure all plant & evaporator cases are

running close to their designed setpoints and that defrost are

operating correctly. Also ensure any manual plant override

systems are set accordingly to allow the oating up of suction

pressure.

This feature is available on all supported

AK-SM Evap & Pack controllers.

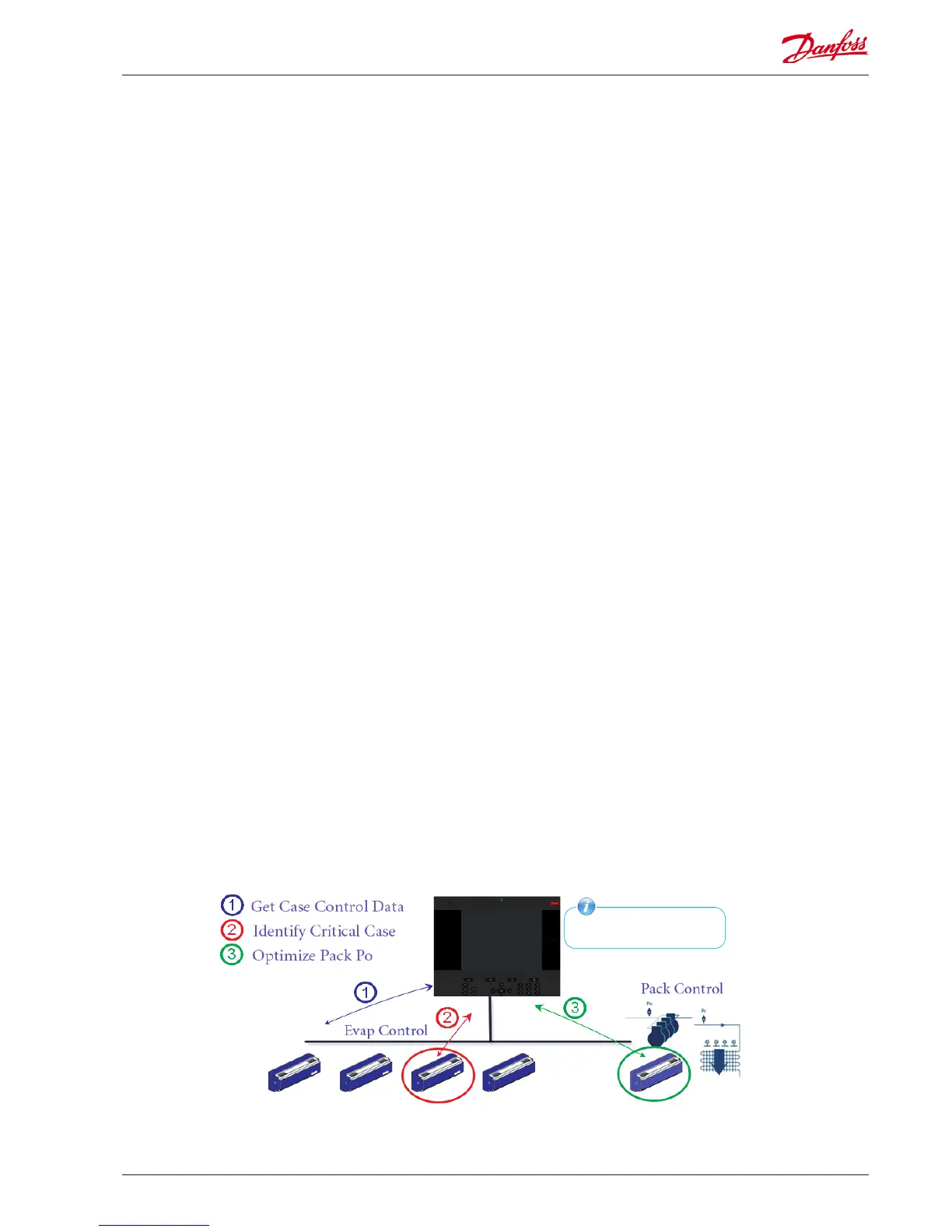

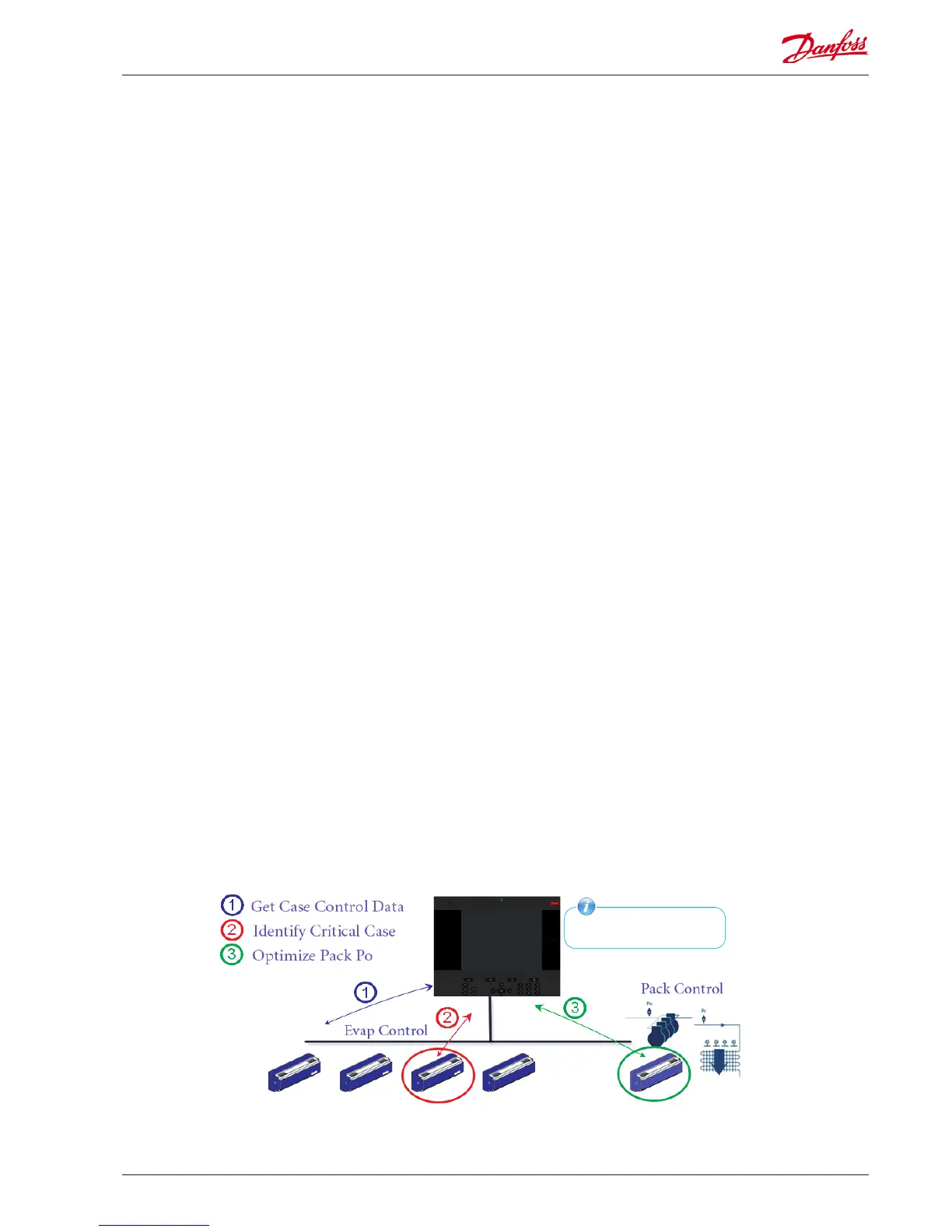

Theory of operation

The Po Optimize function uses a calculation on all controllers to

determine a “Load Factor”. This has been developed by Danfoss

and is available in your AK-SM. By use of the Load Factor the Most

Loaded Case (MLC) is constantly updated.

Floating of the Suction Setpoint is then determined at any given

time by the MLC

1/ The AK-SM continuously receives operating information

from each (Po enabled) controller connected on the network.

The AK-SM is looking for the 'Most loaded case' (MLC).

Each evaporator is analyzed to see if it's current operating

temperature is within a calculated MLC 'target window'.

During defrost and including after defrost recovery, the Po

Optimization will temporarily remove the case from the Po

calculation loop. This ensures that normal system uctuations

(due to defrost etc) do not eect the overall operation of Po

Optimization.

2/ In eect the continuous Po Optimization is looking for the

evaporator that is under the heaviest load (the one that has to

work the hardest to maintain temperature), but still falls within

the MLC target 'window'

3/ Based on the MLC the Po optimization function will then send a

control signal to the Pack controller to optimize the running

suction pressure, i.e. oat the pressure up (based on the max

limit set in the Pack conguration page). As the Pack controller

allows the suction pressure to increase the AK-SM monitors the

complete network and ensures that the refrigerating system as

a whole is stable. This then is a continuous function that once

set runs automatically and ensures the refrigeration system is

running to the best conditions.

AK-SM 850 User Guide Lit. no. USCO.PI.R1.E1.02 © Danfoss 07-2013 41

Loading...

Loading...