4.6 AC Mains Connection

•

Size the wiring based on the input current of the

frequency converter. For maximum wire sizes, see

chapter 8.1 Electrical Data.

•

Comply with local and national electrical codes

for cable sizes.

Procedure

1. Connect the 3-phase AC input power wiring to

terminals L1, L2, and L3 (see Illustration 4.5).

2. Depending on the conguration of the

equipment, connect the input power to the

mains input terminals or the input disconnect.

3. Ground the cable in accordance with the

grounding instructions provided in

chapter 4.3 Grounding.

4. When supplied from an isolated mains source (IT

mains or oating delta) or TT/TN-S mains with a

grounded leg (grounded delta), ensure that

parameter 14-50 RFI Filter is set to [0] O. This

setting prevents damage to the DC link and

reduces ground capacity currents in accordance

with IEC 61800-3.

4.7

Control Wiring

•

Isolate the control wiring from the high-power

components in the frequency converter.

•

When the frequency converter is connected to a

thermistor, ensure that the thermistor control

wiring is shielded and reinforced/double

insulated. A 24 V DC supply voltage is

recommended.

4.7.1 Safe Torque O (STO)

To run STO, more wiring for the frequency converter is

required. Refer to VLT

®

Frequency Converters Safe Torque O

Operating Guide for further information.

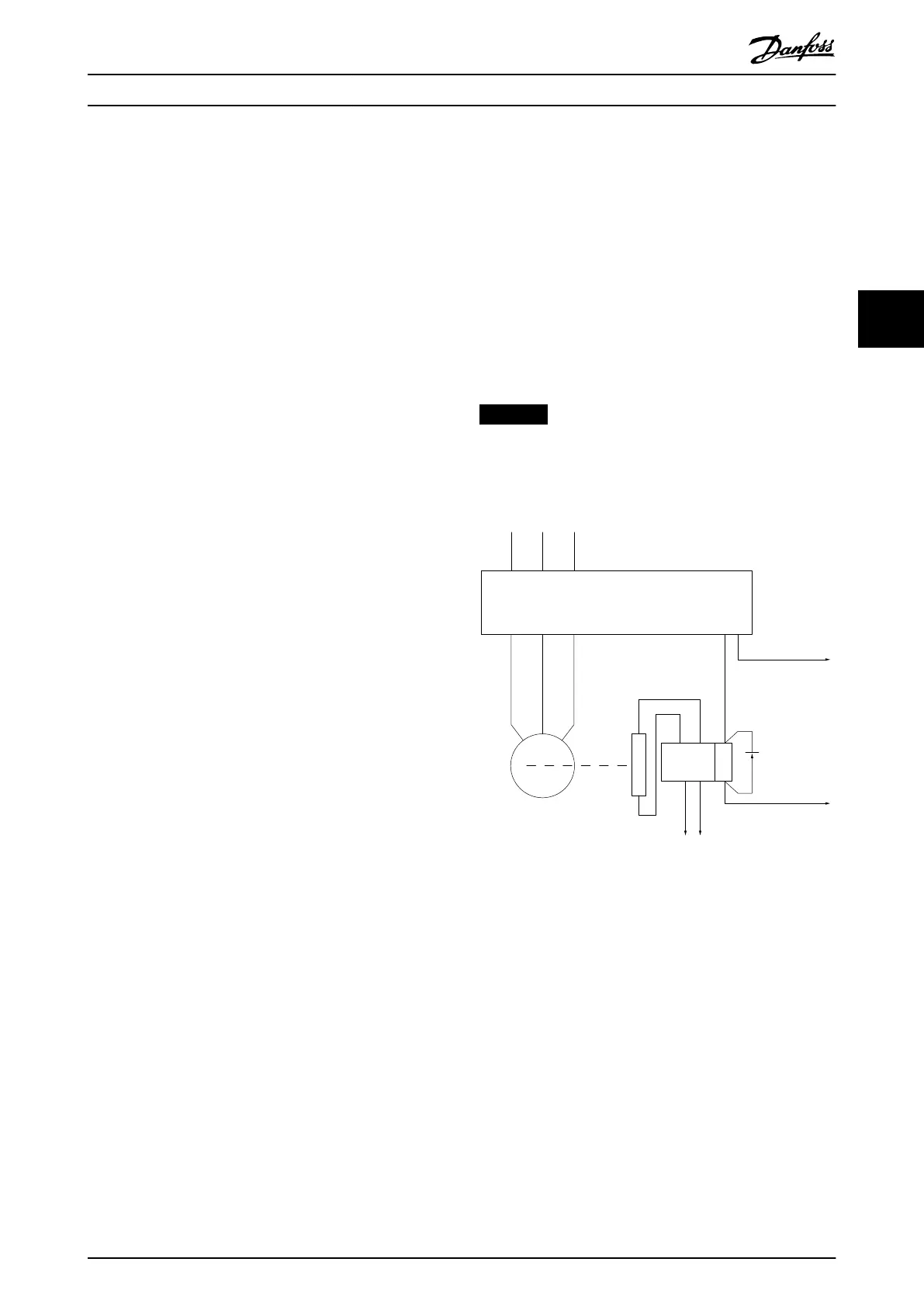

4.7.2 Mechanical Brake Control

In hoisting/lowering applications, it is necessary to

control an electro-mechanical brake.

•

Control the brake using any relay output or

digital output (terminal 27 or 29).

•

Keep the output closed (voltage-free) as long as

the frequency converter is unable to keep the

motor at standstill, for example due to the load

being too heavy.

•

Select [32] Mechanical brake control in parameter

group 5-4* Relays for applications with an electro-

mechanical brake.

•

The brake is released when the motor current

exceeds the value in parameter 2-20 Release Brake

Current.

•

The brake is engaged when the output frequency

is less than the frequency set in

parameter 2-21 Activate Brake Speed [RPM] or

parameter 2-22 Activate Brake Speed [Hz], and only

if the frequency converter carries out a stop

command.

If the frequency converter is in alarm mode or in an

overvoltage situation, the mechanical brake immediately

closes.

NOTICE

The frequency converter is not a safety device. It is the

responsibility of the system designer to integrate safety

devices according to relevant national crane/lift

regulations.

130BA902.10

L1 L2 L3

U V W

02 01

A1

A2

Frequency converter

Output

relay

Command circuit

220 V AC

Mechanical

brake

Shaft

Motor

Freewheeling

diode

Brake

380 V AC

Output

contactor

input

power circuit

Illustration 4.6 Connecting the Mechanical Brake to the

Frequency Converter

Electrical Installation Operating Guide

MG33AT02 Danfoss A/S © 05/2018 All rights reserved. 15

4 4

Loading...

Loading...