For more information about EMC, see chapter 4.2 EMC-compliant Installation

NOTICE

EMC INTERFERENCE

Use shielded cables for motor and control wiring, and

separate cables for input power, motor wiring, and

control wiring. Failure to isolate power, motor, and

control cables can result in unintended behavior or

reduced performance. Minimum 200 mm (7.9 in)

clearance is required between power, motor, and control

cables.

4.5 Motor Connection

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables that run

together can charge equipment capacitors, even with the

equipment turned o and locked out. Failure to run

output motor cables separately or use shielded cables

could result in death or serious injury.

•

Run output motor cables separately, or

•

Use shielded cables.

•

Comply with local and national electrical codes

for cable sizes. For maximum wire sizes, see

chapter 8.1 Electrical Data.

•

Follow motor manufacturer wiring requirements.

•

Motor wiring knockouts or access panels are

provided at the base of IP21 (NEMA1/12) and

higher units.

•

Do not wire a starting or pole-changing device

(for example Dahlander motor or slip ring

asynchronous motor) between the frequency

converter and the motor.

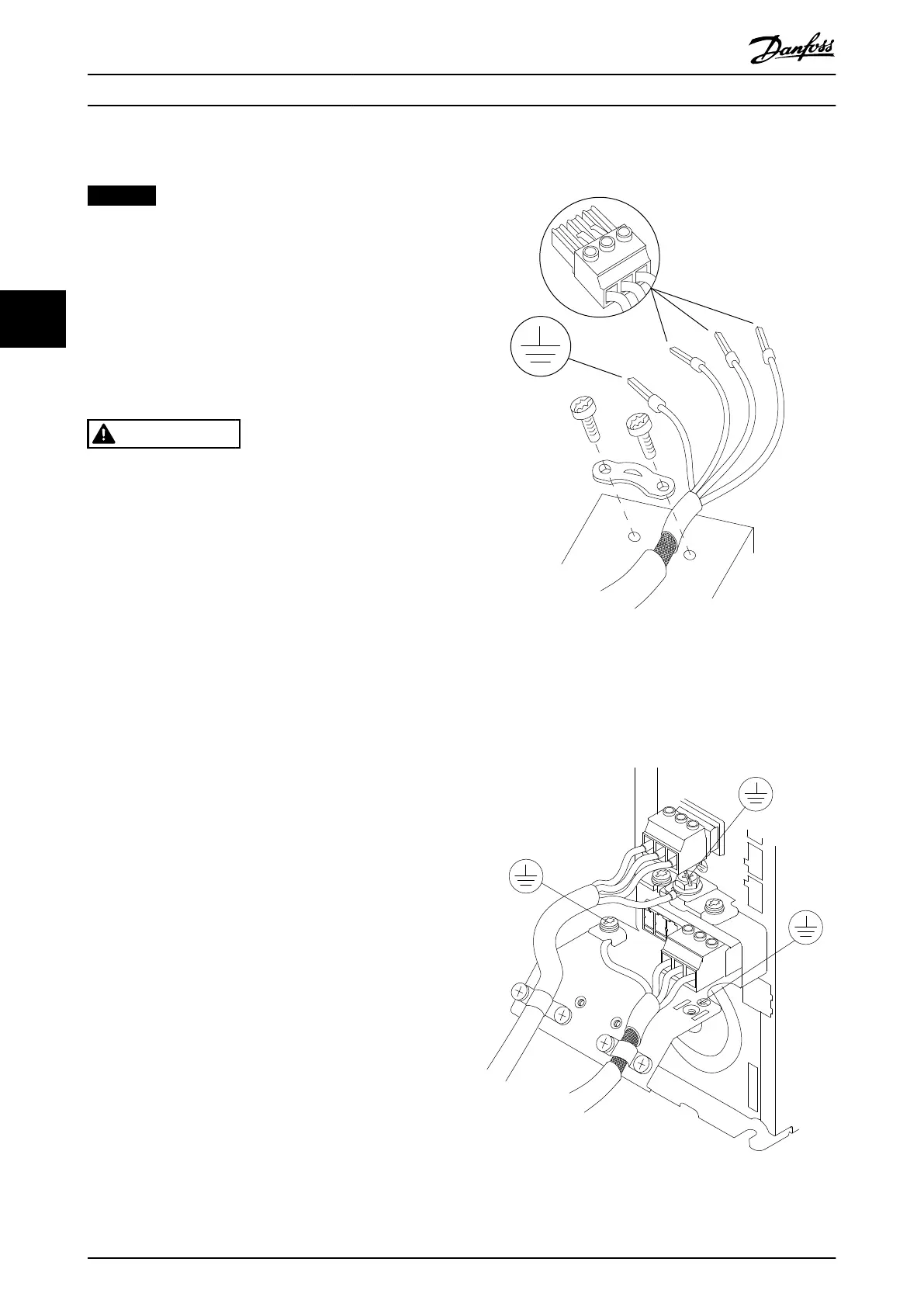

Procedure for grounding the cable shield

1. Strip a section of the outer cable insulation.

2. Position the stripped wire under the cable clamp

to establish mechanical xation and electrical

contact between the cable shield and ground.

3. Connect the ground wire to the nearest

grounding terminal in accordance with the

grounding instructions provided in

chapter 4.3 Grounding, see Illustration 4.4.

4. Connect the 3-phase motor wiring to terminals

96 (U), 97 (V), and 98 (W), see Illustration 4.4.

5. Tighten the terminals in accordance with the

information provided in chapter 8.8 Connection

Tightening Torques.

Illustration 4.4 Motor Connection

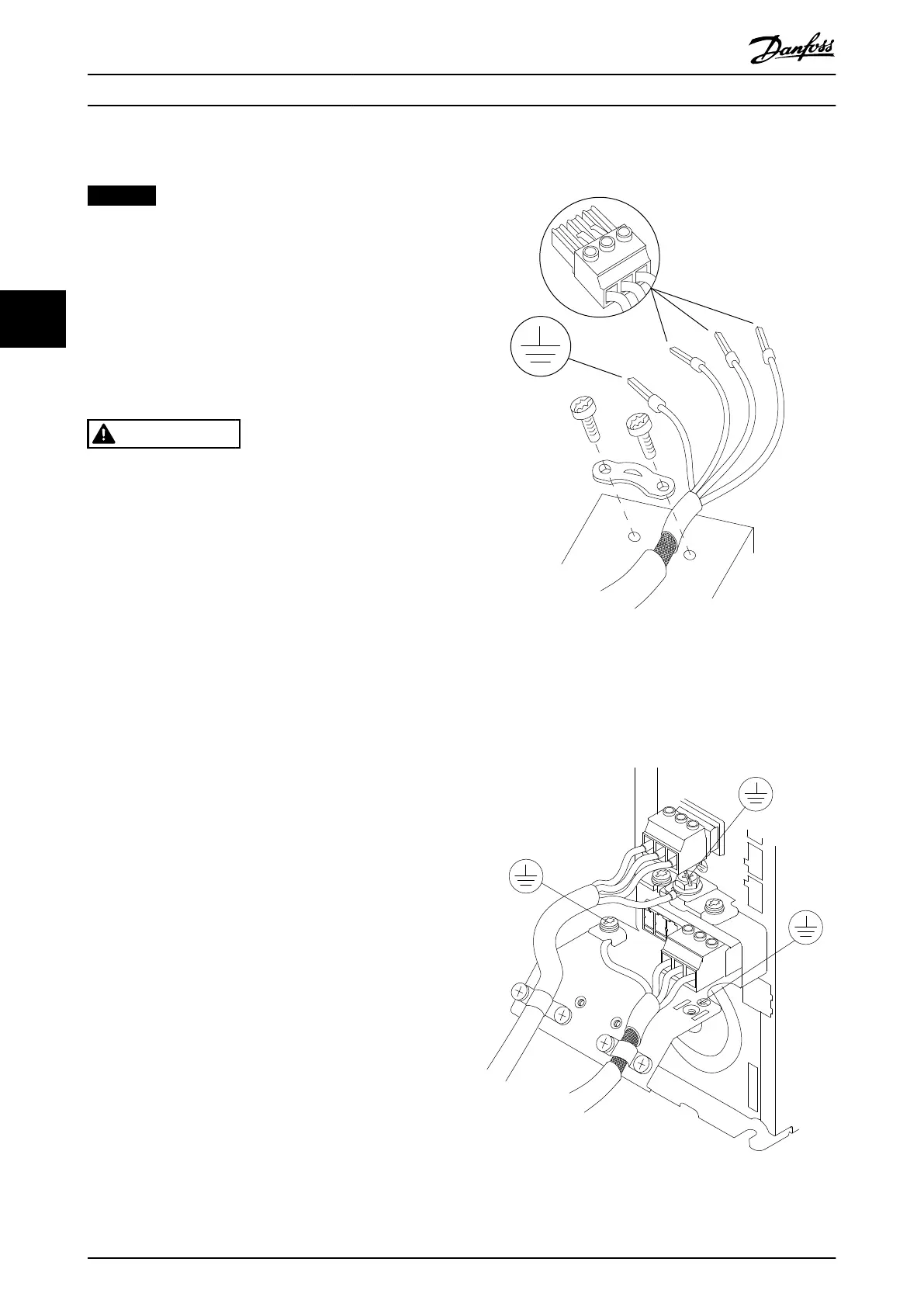

Illustration 4.5 shows mains input, motor, and grounding

for basic frequency converters. Actual congurations vary

with unit types and optional equipment.

Illustration 4.5 Example of Motor, Mains, and Ground Wiring

Electrical Installation

VLT

®

AutomationDrive FC 301/302

14 Danfoss A/S © 05/2018 All rights reserved. MG33AT02

44

Loading...

Loading...