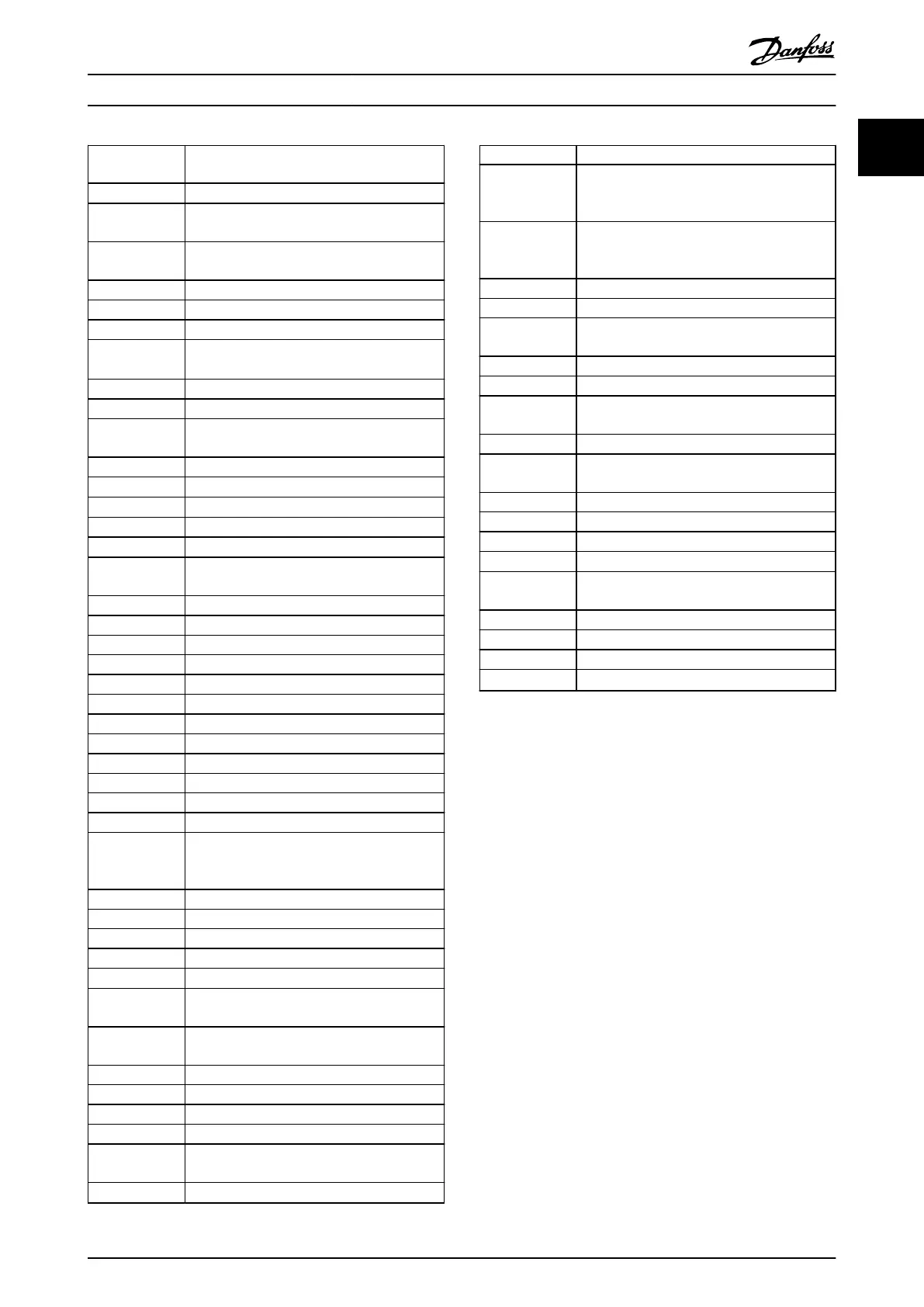

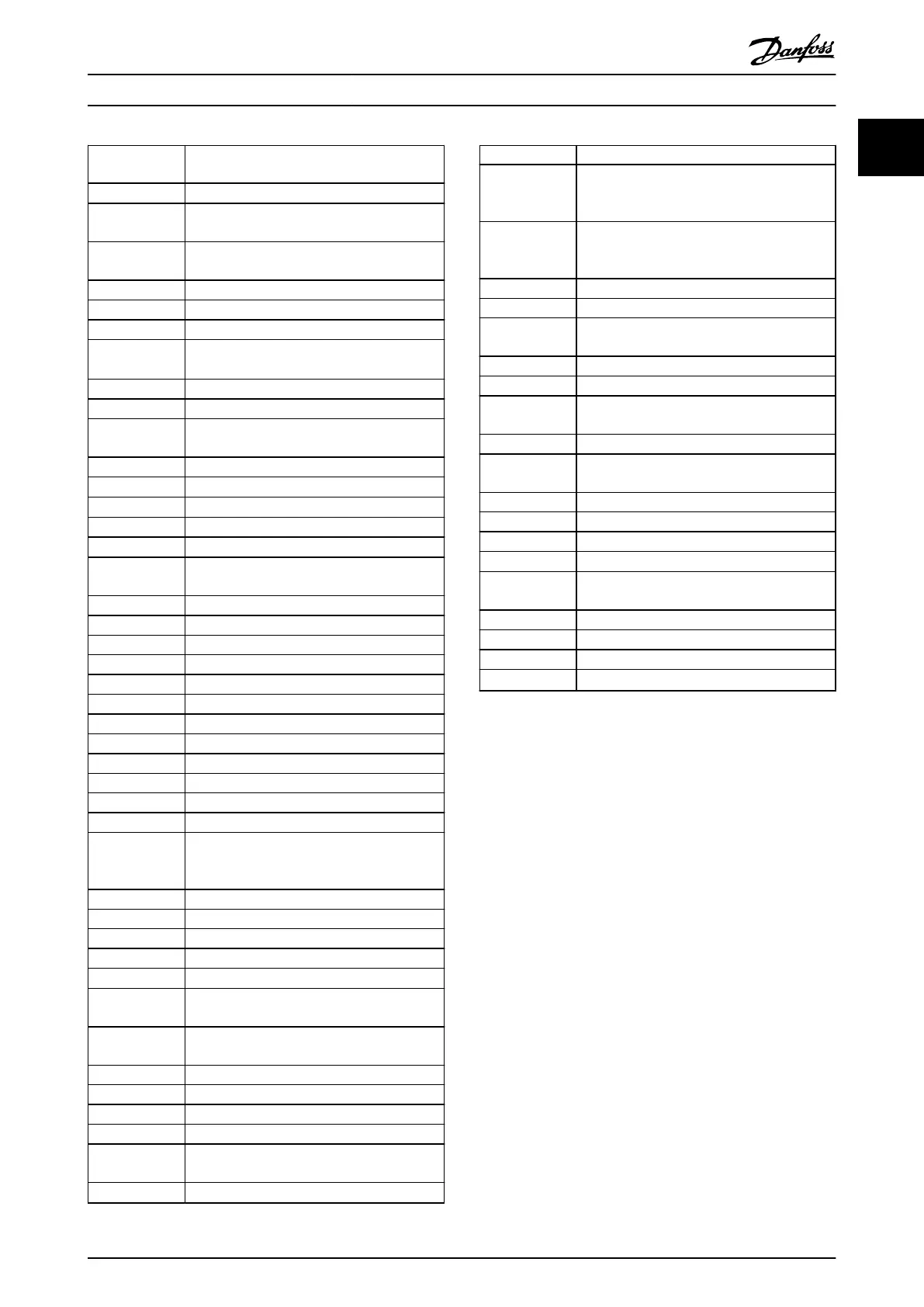

f

JOG

Motor frequency when jog function is

activated.

f

M

Motor frequency

f

MAX

Maximum output frequency, the frequency

converter applies on its output.

f

MIN

Minimum motor frequency from the frequency

converter

f

M,N

Nominal motor frequency

FC Frequency converter

g Gramme

Hiperface

®

Hiperface

®

is a registered trademark by

Stegmann

HO High overload

hp Horse power

HTL HTL encoder (10–30 V) pulses - High-voltage

transistor logic

Hz Hertz

I

INV

Rated inverter output current

I

LIM

Current limit

I

M,N

Nominal motor current

I

VLT,MAX

Maximum output current

I

VLT,N

Rated output current supplied by the

frequency converter

kHz Kilohertz

LCP Local control panel

lsb Least signicant bit

m Meter

mA Milliampere

MCM Mille circular mil

MCT Motion control tool

mH Inductance in milli Henry

min Minute

mm Millimeter

ms Millisecond

msb Most signicant bit

η

VLT

Eciency of the frequency converter dened

as ratio between power output and power

input.

nF Capacitance in nano Farad

NLCP Numerical local control panel

Nm Newton meter

NO Normal overload

n

s

Synchronous motor speed

Online/Oine

Parameters

Changes to online parameters are activated

immediately after the data value is changed.

P

br,cont.

Rated power of the brake resistor (average

power during continuous braking).

PCB Printed circuit board

PCD Process data

PDS Power drive system: a CDM and a motor

PELV Protective extra low voltage

P

m

Frequency converter nominal output power as

high overload (HO).

P

M,N

Nominal motor power

PM motor Permanent magnet motor

Process PID PID (Proportional Integrated Dierential)

regulator that maintains the desired speed,

pressure, temperature, and so on.

R

br,nom

Nominal resistor value that ensures a brake

power on motor shaft of 150/160% for 1

minute

RCD Residual current device

Regen Regenerative terminals

R

min

Minimum permissible brake resistor value by

frequency converter

RMS Root mean square

RPM Revolutions per minute

R

rec

Recommended brake resistor resistance of

Danfoss brake resistors

s Second

SFAVM Stator ux-oriented asynchronous vector

modulation

STW Status word

SMPS Switch mode power supply

THD Total harmonic distortion

T

LIM

Torque limit

TTL TTL encoder (5 V) pulses - transistor transistor

logic

U

M,N

Nominal motor voltage

V Volts

VT Variable torque

VVC

+

Voltage vector control plus

Table 1.2 Abbreviations

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of

illustrations.

Italicised text indicates:

•

Cross reference

•

Link

•

Footnote

•

Parameter name, parameter group name,

parameter option

All dimensions are in mm (inch).

* indicates a default setting of a parameter.

•

VLT

®

HVAC Drive FC 102 Operating Instructions

provides information on mechanical and electrical

installation of the frequency converter.

•

VLT

®

HVAC Drive FC 102 Design Guide holds all

technical information about the frequency

converter, customer design, and applications.

•

VLT

®

HVAC Drive FC 102 Programming Guide

provides information on how to programme and

includes complete parameter descriptions.

•

Application Note, Temperature Derating Guide.

Introduction

Programming Guide

MG11CE02 Danfoss A/S © 03/2015 All rights reserved. 5

1

1

Loading...

Loading...