NOTICE

The ETR timer function does not work when 1-10 Motor

Construction = [1] PM, non salient SPM.

NOTICE

For correct operation of the ETR function, the setting in

parameter 1-03 Torque Characteristics must fit the

application (see description of parameter 1-03 Torque

Characteristics).

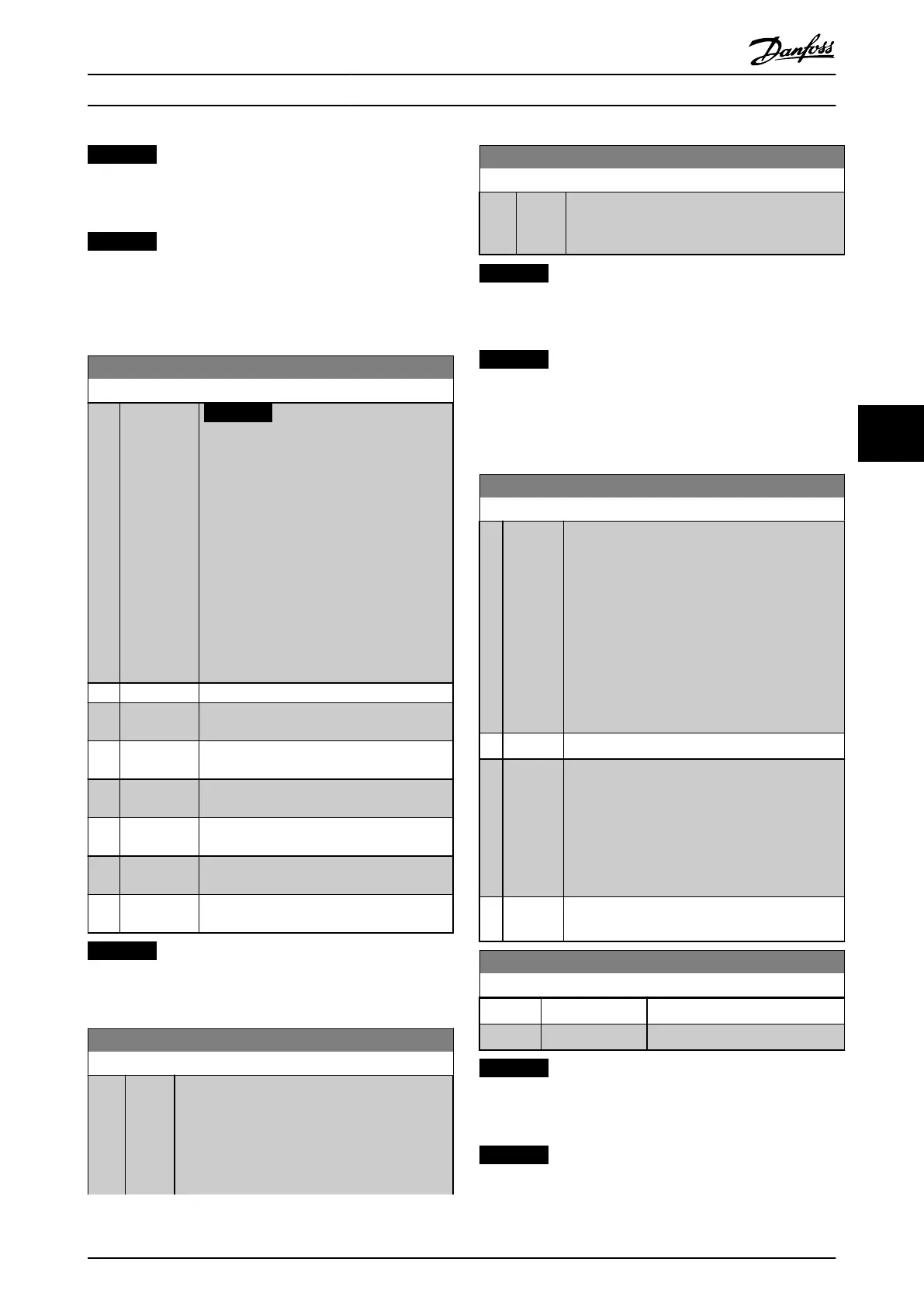

1-93 Thermistor Source

Option: Function:

NOTICE

This parameter cannot be adjusted

while the motor is running.

Select the input to which the thermistor (PTC

sensor) should be connected. An analog

input option [1] Analog Input 53 or [2] Analog

Input 54 cannot be selected if the analog

input is already in use as a reference source

(selected in parameter 3-15 Reference 1

Source, parameter 3-16 Reference 2 Source or

3-17 Reference 3 Source).

When using MCB 112, [0] None must always

be selected.

[0] * None

[1] Analog

Input 53

[2] Analog

Input 54

[3] Digital input

18

[4] Digital input

19

[5] Digital input

32

[6] Digital input

33

NOTICE

Digital input should be set to [0] PNP - Active at 24 V in

5-00 Digital I/O Mode.

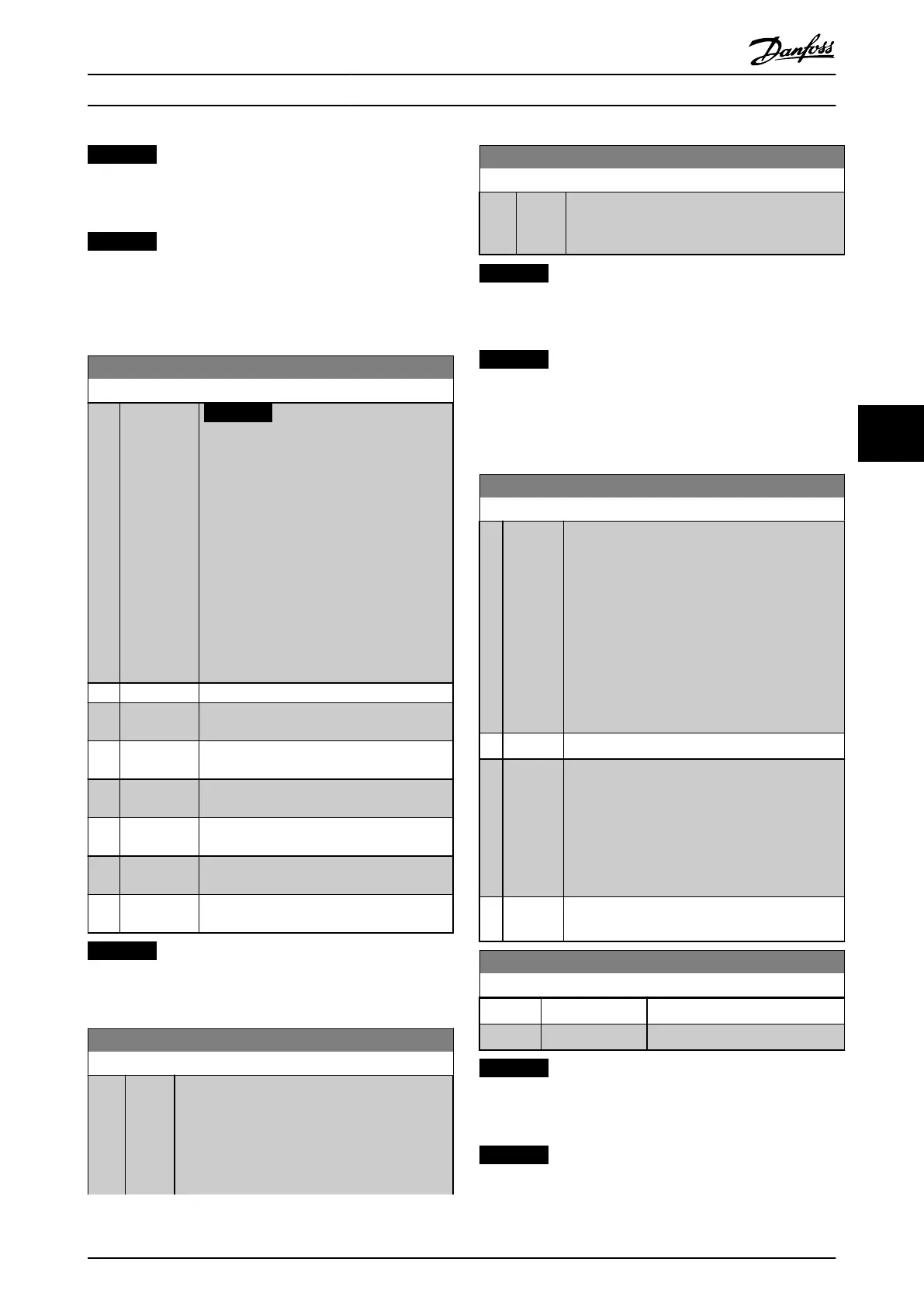

2-00 DC Hold/Preheat Current

Range: Function:

50

%*

[ 0 -

160 %]

Enter a value for holding current as a percentage

of the rated motor current I

M,N

set in

parameter 1-24 Motor Current. 100% DC holding

current corresponds to I

M,N

.

This parameter holds the motor (holding torque)

or pre-heats the motor.

2-00 DC Hold/Preheat Current

Range: Function:

This parameter is active if [1] DC hold/Motor

Preheat is selected in parameter 1-80 Function at

Stop.

NOTICE

Parameter 2-00 DC Hold/Preheat Current have no effect

when 1-10 Motor Construction = [1] PM, non salient SPM.

NOTICE

The maximum value depends on the rated motor

current.

Avoid 100 % current for too long. It may damage the

motor.

2-10 Brake Function

Option: Function:

Available selections depend on 1-10 Motor

Construction:

[0] Asynchron:

[0] Off

[1] Resistor brake

[2] AC brake

[1] PM non salient:

[0] Off

[1] Resistor brake

[0] Off No brake resistor installed.

[1] Resistor

brake

Brake resistor incorporated in the system, for

dissipation of surplus brake energy as heat.

Connecting a brake resistor allows a higher DC-

link voltage during braking (generating operation).

The resistor brake function is only active in

frequency converters with an integral dynamic

brake.

[2] AC brake AC Brake only works in compressor torque mode

in parameter 1-03 Torque Characteristics.

2-17 Over-voltage Control

Option: Function:

[0] Disabled No OVC required.

[2] * Enabled Activates OVC.

NOTICE

Parameter 2-17 Over-voltage Control has no effect when

1-10 Motor Construction = [1] PM, non salient SPM.

NOTICE

The ramp time is automatically adjusted to avoid

tripping of the frequency converter.

How to Programme VLT HVAC Drive FC 102 Operating Instructions

MG11F402 - Rev. 2013-12-16 95

6 6

Loading...

Loading...