Response time

The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to

zero (deceleration) is a function of the size of the orifice in the control flow passage, charge pressure,

valve plate and other vehicle dynamics.

A range of orifice sizes is available for the Series 90 Electric Displacement Control to assist in matching the

rate of swashplate response to the acceleration and deceleration requirements of the application. Testing

should be carried out to determine the proper orifice selection for the desired response.

For more information regarding response times for individual orifices, contact your Danfoss

representative.

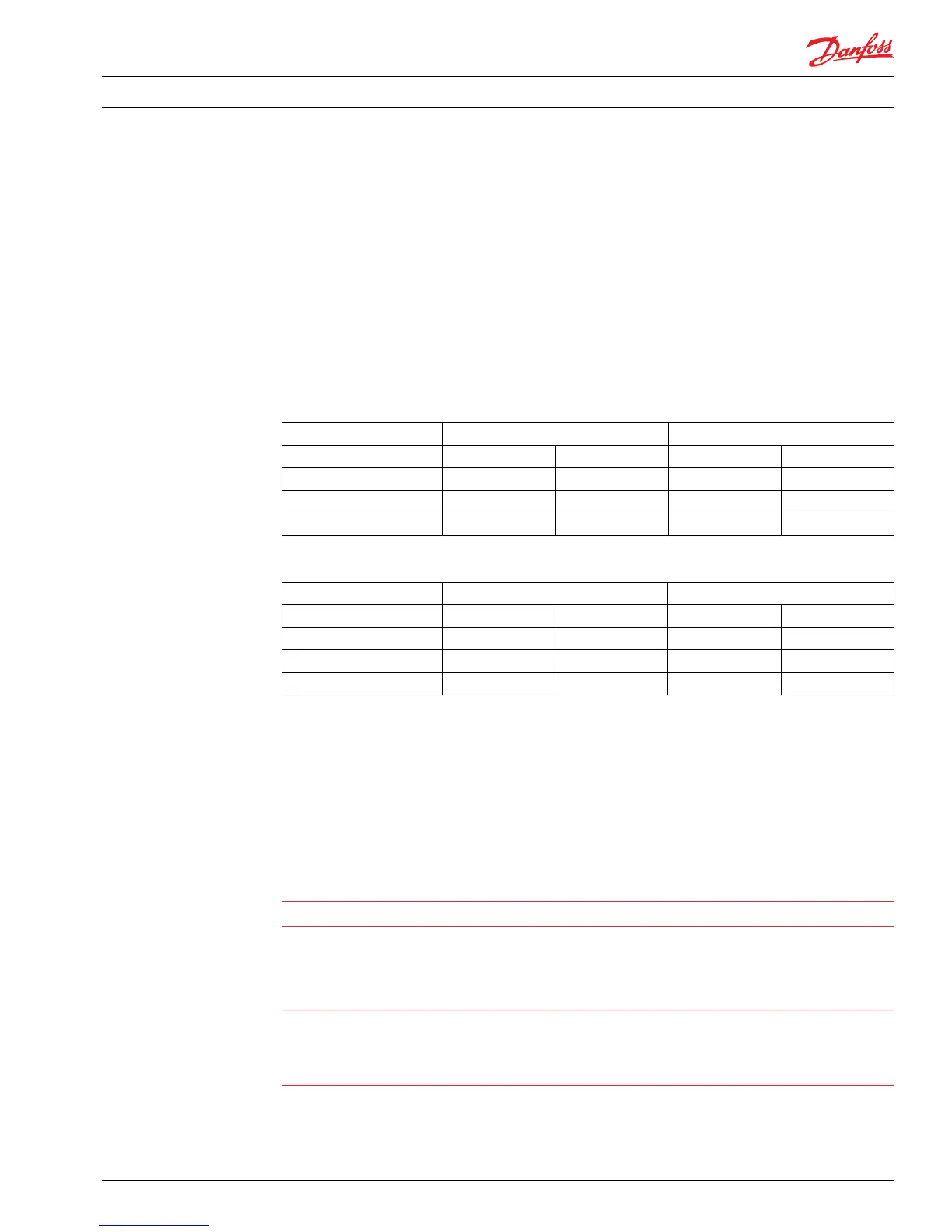

Pump output flow direction vs. control current

EDC using a single coil or dual coils in parallel (A and C common, B and D common)

Input shaft rotation CW CCW

Positive current to term A or C B or D A or C B or D

Port A flow (M1) Out In In Out

Port B flow (M2) In Out Out In

Servo cylinder (side) M5 (2) M4 (1) M5 (2) M4 (1)

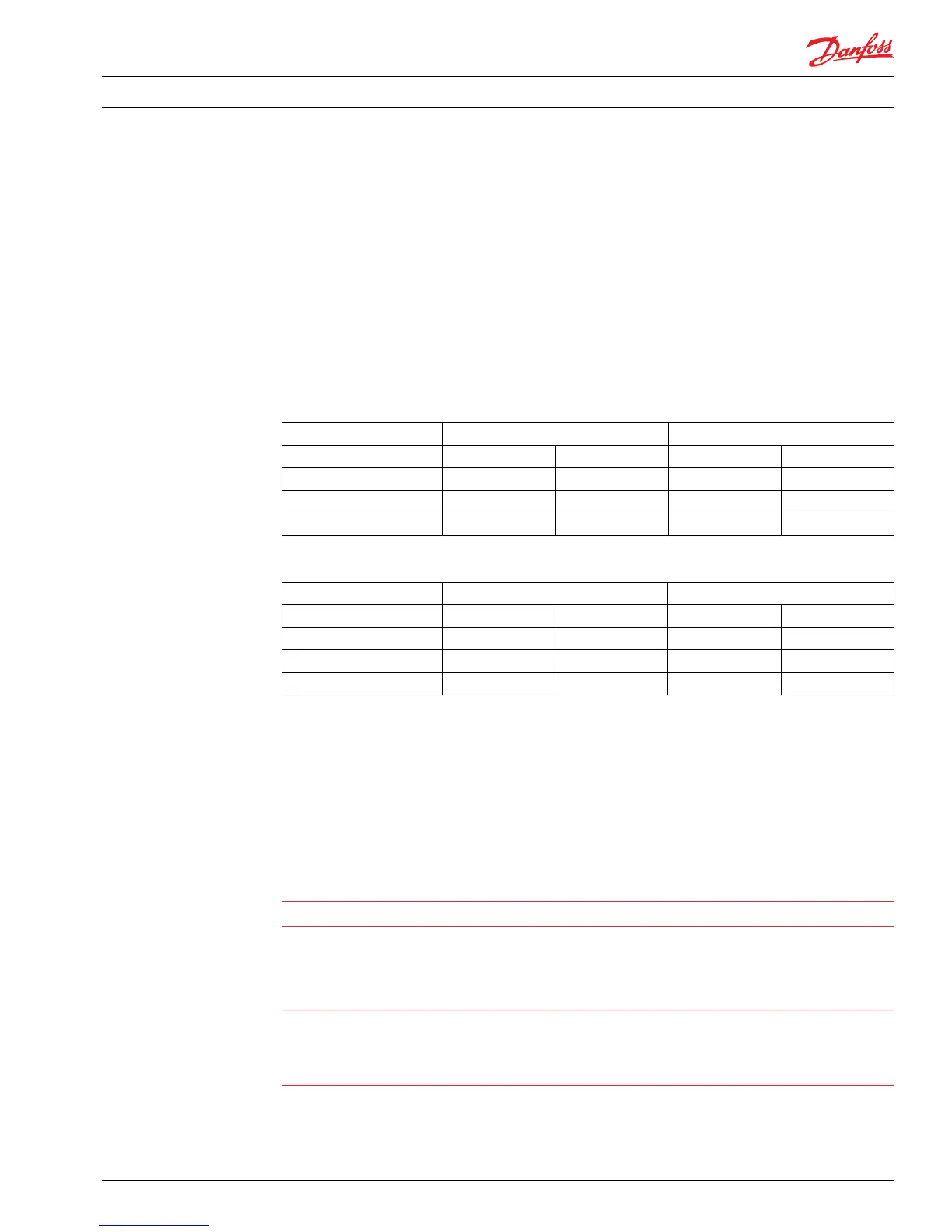

EDC using a dual coil in series (B and C common)

Input shaft rotation CW CCW

Positive current to term A D A D

Port A flow (M1) Out In In Out

Port B flow (M2) In Out Out In

Servo cylinder (side) M5 (2) M4 (1) M5 (2) M4 (1)

Refer to Installation Drawings on page 50 for port locations.

For further information on EDC controls, refer to Electrical Displacement Control For Series 90 Pumps,

BLN-95-9060.

Manual Over Ride (MOR)

EDC controls are available with a Manual Over Ride (MOR) which is intended for temporary actuation of

the control to aid in pump diagnostics.

Warning

The vehicle must always be in a safe condition (i.e. vehicle lifted off the ground) when using the MOR

function. The MOR lever has a must be manually actuated to be engaged. Moving the plunger

mechanically moves the pilot stage armature which allows the pump to go on stroke. The MOR should be

engaged anticipating a full stroke response from the pump.

Technical Information

Series 90 Axial Piston Pumps

Control Options

520L0603 • Rev 0804 • March 2016 31

Loading...

Loading...