Warning

Unintended MOR operation will cause the pump to go into stroke.

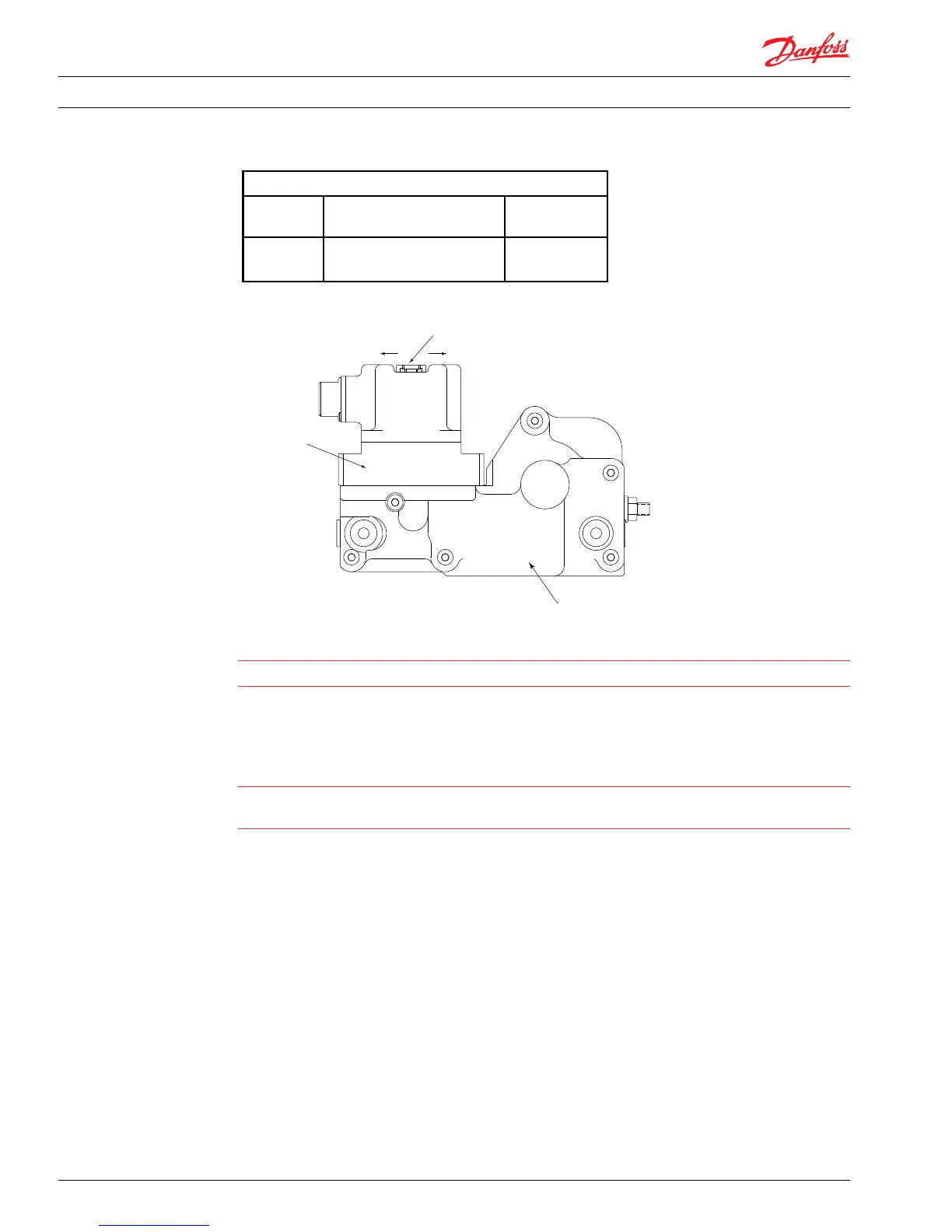

Hydraulic Displacement Control (HDC), Option HF

Warning

Avoid designing a system which puts swashplate into full stroke when control operation is blocked by

contamination.

Operation

The hydraulic displacement control uses a hydraulic input signal to operate a 4-way servo valve, which

ports hydraulic pressure to either side of a double acting servo piston. The servo piston tilts the cradle

swashplate, thus varying the pump's displacement from full displacement in one direction to full

displacement in the opposite direction.

The control has a mechanical feedback mechanism which moves the servo valve in relation to the input

signal and the angular rotation of the swashplate. The hydraulic displacement control is designed so the

angular position of the swashplate (pump displacement) is proportional to the hydraulic input signal

pressure. Due to normal operating force changes, the swashplate tends to drift from the position preset

by the machine operator. Drift, sensed by feedback linkage system connecting the swashplate to the

control valve, activates the valve to supply pressure to the servo piston, maintaining the swashplate in its

preset position.

Features and Benefits

•

The hydraulic displacement control is a high gain control: With only small change of the input signal,

the servo valve moves to a full open position porting maximum flow to the servo cylinder.

Technical Information

Series 90 Axial Piston Pumps

Control Options

32 520L0603 • Rev 0804 • March 2016

Loading...

Loading...