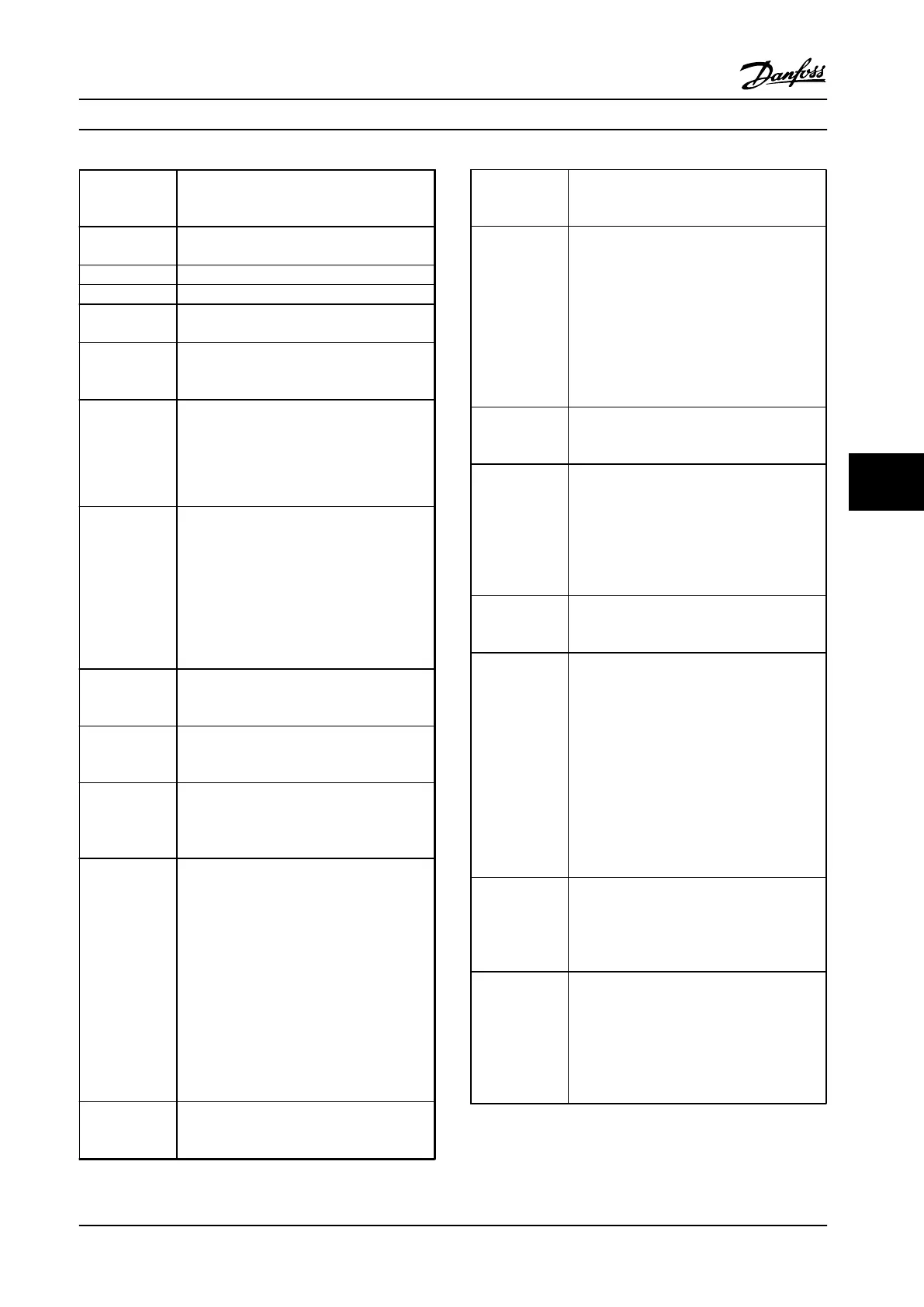

AC Brake

AC Brake was selected in 2-10 Brake Function.

The AC brake overmagnetizes the motor to

achieve a controlled slow-down.

AMA finish OK Automatic motor adaptation (AMA) was

carried out successfully.

AMA ready AMA is ready to start. Press [Hand On] to start.

AMA running AMA process is in progress.

Braking The brake chopper is in operation. Generative

energy is absorbed by the brake resistor.

Braking max. The brake chopper is in operation. The power

limit for the brake resistor defined in

2-12 Brake Power Limit (kW) has been reached.

Coast

•

Coast inverse was selected as a function for

a digital input (parameter group 5-1*

Digital Inputs). The corresponding terminal

is not connected.

•

Coast activated by serial communication.

Ctrl. ramp-down

[1] Control Ramp-down was selected in

14-10 Mains Failure.

•

The AC line voltage is below the value set

in 14-11 Mains Voltage at Mains Fault at

line power fault

•

The adjustable frequency drive ramps

down the motor using a controlled ramp-

down.

Current High The adjustable frequency drive output current

is above the limit set in 4-51 Warning Current

High.

Current Low The adjustable frequency drive output current

is below the limit set in 4-52 Warning Speed

Low.

DC Hold

[1] DC Hold is selected in 1-80 Function at Stop

and a stop command is active. The motor is

held by a DC current set in 2-00 DC Hold/

Preheat Current.

DC Stop

The motor is held with a DC current (2-01 DC

Brake Current) for a specified time (2-02 DC

Braking Time).

•

The DC Brake cut-in speed is reached in

2-03 DC Brake Cut-in Speed [RPM] and a

stop command is active.

•

DC Brake (inverse) is selected as a function

for a digital input (parameter group 5-1*

Digital Inputs). The corresponding terminal

is not active.

•

The DC Brake is activated via serial

communication.

Feedback high The sum of all active feedbacks is above the

feedback limit set in 4-57 Warning Feedback

High.

Feedback low The sum of all active feedbacks is below the

feedback limit set in 4-56 Warning Feedback

Low.

Freeze output The remote reference is active, which holds

the present speed.

•

Freeze output was selected as a function

for a digital input (parameter group 5-1*

Digital Inputs). The corresponding terminal

is active. Speed control is only possible via

the terminal functions Speed Up and Slow.

•

Hold ramp is activated via serial communi-

cation.

Freeze output

request

A freeze output command was given but the

motor remains stopped until a run permissive

signal is received.

Freeze ref.

Freeze Reference was selected as a function for

a digital input (parameter group 5-1* Digital

Inputs). The corresponding terminal is active.

The adjustable frequency drive saves the

actual reference. Changing the reference is

now only possible via terminal functions Speed

Up and Slow.

Jog request A jog command was given but the motor

remains stopped until a run permissive signal

is received via a digital input.

Jogging The motor is running as programmed in

3-19 Jog Speed [RPM].

•

Jog was selected as a function for a digital

input (parameter group 5-1* Digital Inputs).

The corresponding terminal (e.g., Terminal

29) is active.

•

The Jog function is activated via the serial

communication.

•

The Jog function was selected as a

reaction for a monitoring function (e.g., No

signal). The monitoring function is active.

Motor check

In 1-80 Function at Stop, [2] Motor Check was

selected. A stop command is active. To ensure

that a motor is connected to the adjustable

frequency drive, a permanent test current is

applied to the motor.

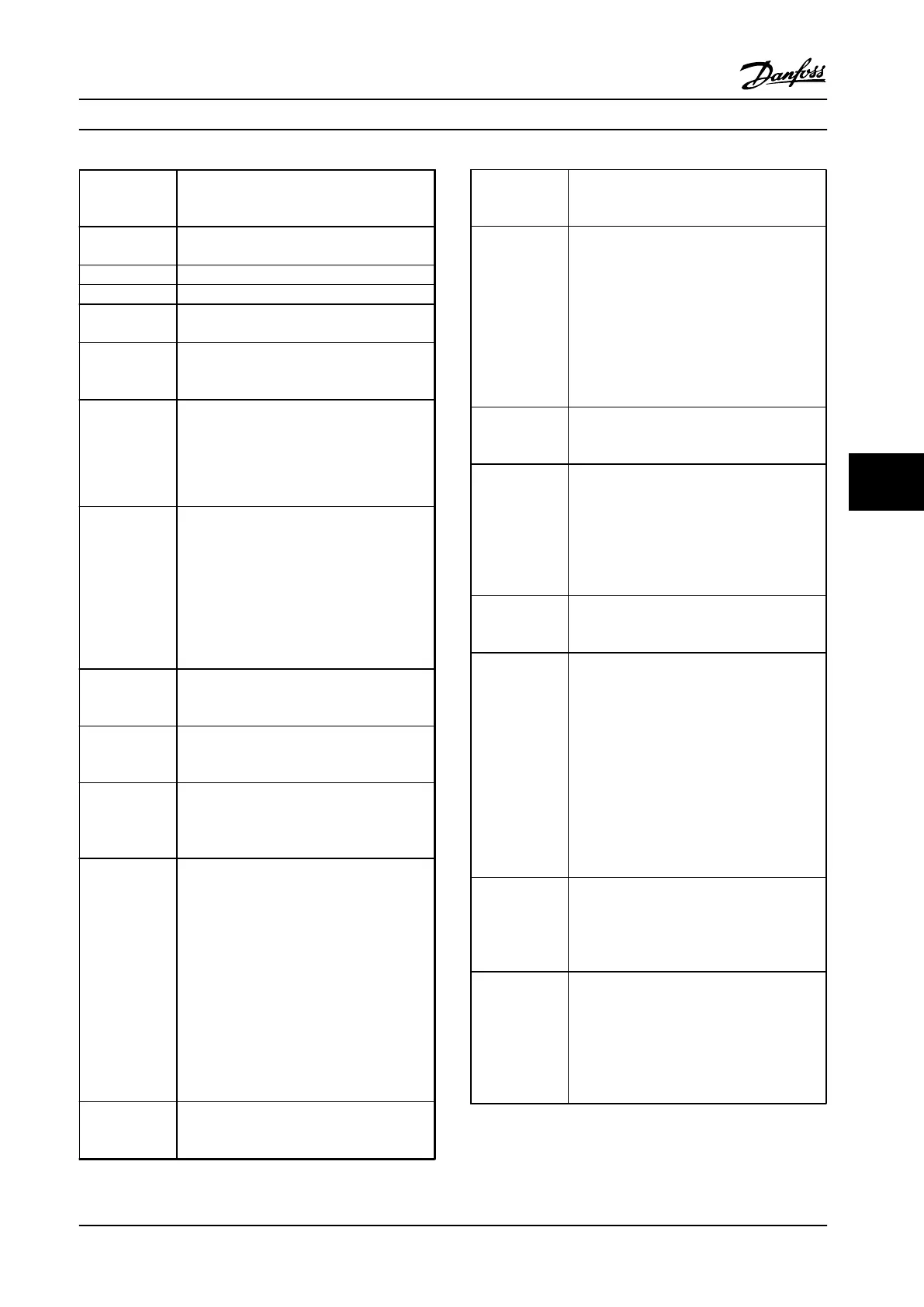

Over-voltage

Control (OVC)

Over-voltage control was activated in

2-17 Over-voltage Control, [2] Enabled. The

connected motor supplies the adjustable

frequency drive with generative energy. Over-

voltage control adjusts the V/Hz ratio to run

the motor in controlled mode and to prevent

the adjustable frequency drive from tripping.

Maintenance, Diagnostics an... Instruction Manual

MG33AP22 Danfoss A/S © Rev. 09/2014 All rights reserved. 39

7 7

Loading...

Loading...