NOTICE!

POTENTIAL EQUALIZATION

Risk of electrical interference, when the ground potential between the adjustable frequency drive and the control

system is different. Install equalizing cables between the system components. Recommended cable cross-section: AWG 6

[16 mm

2

].

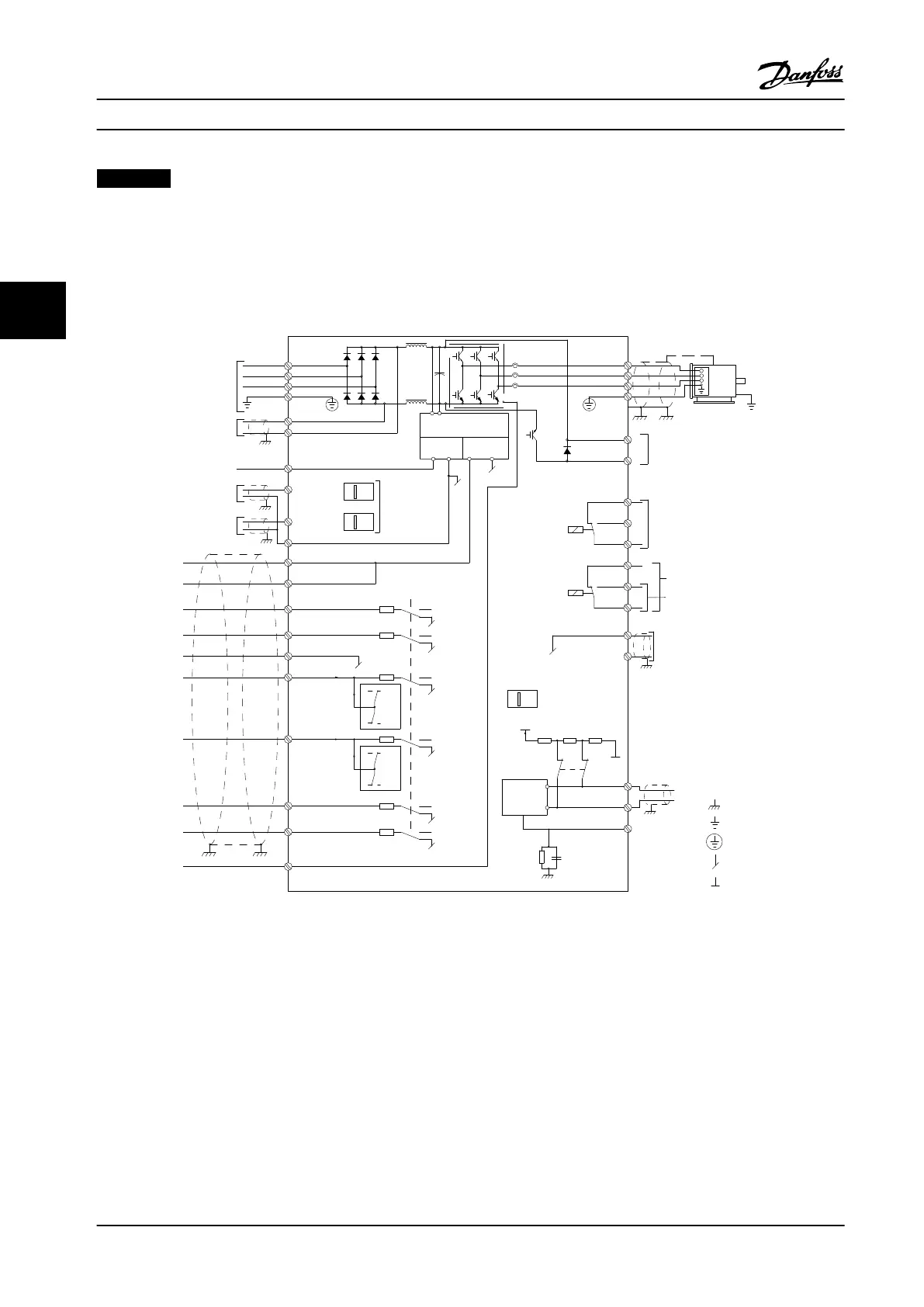

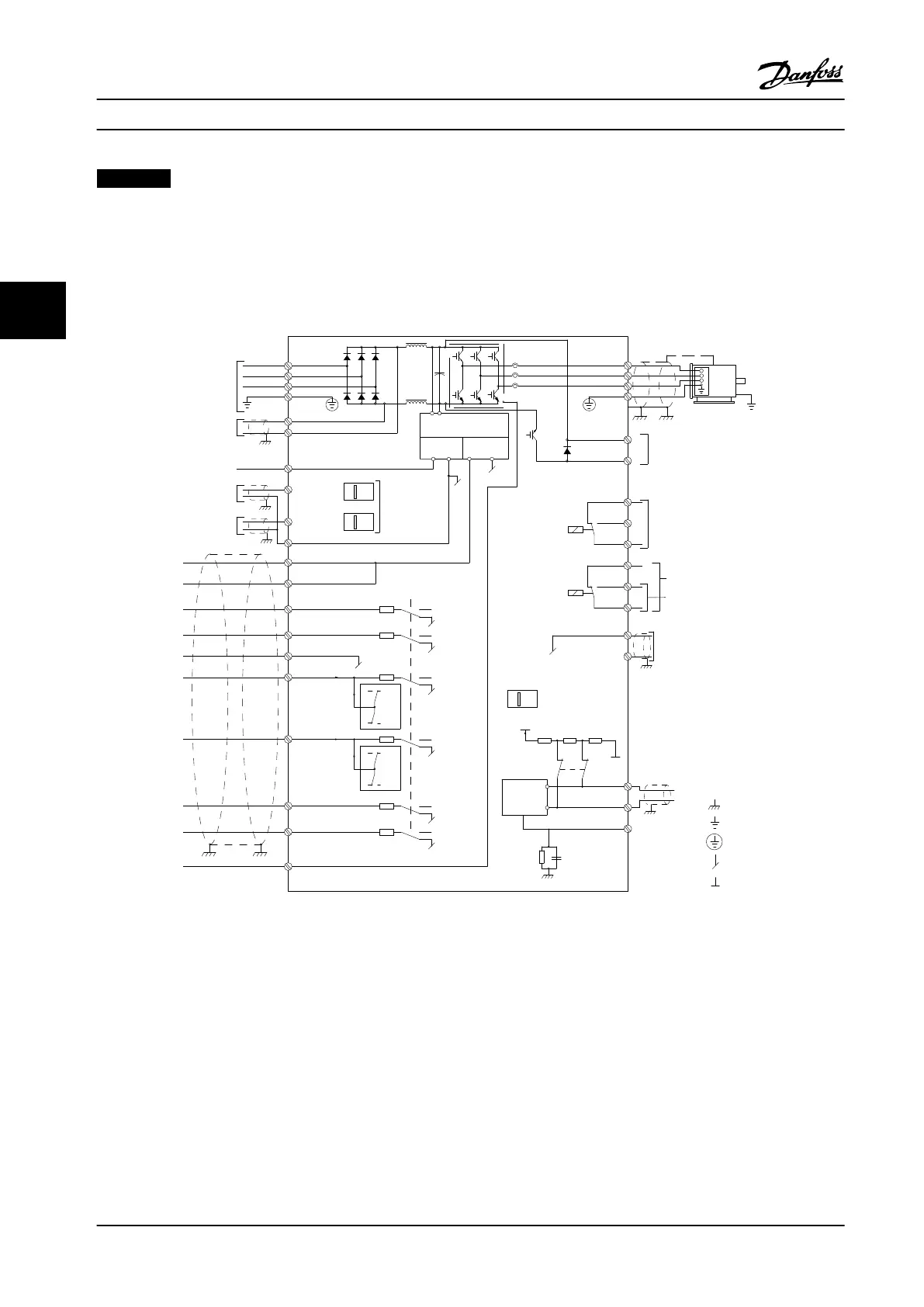

4.4 Wiring Schematic

130BD599.11

3-phase

power

input

DC bus

Switch Mode

Power Supply

Motor

Analog Output

Interface

relay1

relay2

ON=Terminated

OFF=Open

Brake

resistor

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24 V OUT)

13 (+24 V OUT)

37 (D IN)

18 (D IN)

20 (COM D IN)

10 V DC

15 mA 130/200 mA

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0 V

5V

S801

0/4-20 mA

RS-485

RS-485

03

+10 V DC

0/-10 V DC -

+10 V DC

+10 V DC

0/4-20 mA

0/-10 V DC-

240 V AC, 2 A

24 V DC

02

01

05

04

06

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27

24 V

0 V

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

0 V

24 V

29

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON=0/4-20 mA

OFF=0/-10 V DC -

+10 V DC

95

P 5-00

21

ON

S801

(R+) 82

(R-) 81

: Chassis

**

240 V AC, 2 A

400 V AC, 2 A

*

*

*

: Ground

: Ground 1

: Ground 2

: PE

Figure 4.1 Basic Wiring Schematic

A=Analog, D=Digital

*Terminal 37 (optional) is used for Safe Torque Off (STO). For installation instructions, refer to the VLT

®

Safe Torque Off

Instruction Manual. Terminal 37 is not included in FC 301 (except enclosure type A1). Relay 2 and terminal 29 have no

function in FC 301.

**Do not connect cable shield.

Electrical Installation

Instruction Manual

14 Danfoss A/S © Rev. 09/2014 All rights reserved. MG33AP22

44

Loading...

Loading...