VLT

®

AutomationDrive EtherNet/IP

MG.90.Jx.02 ver. 5

th

September 2007 – VLT is a registered Danfoss trademark 12

EMC Precautions

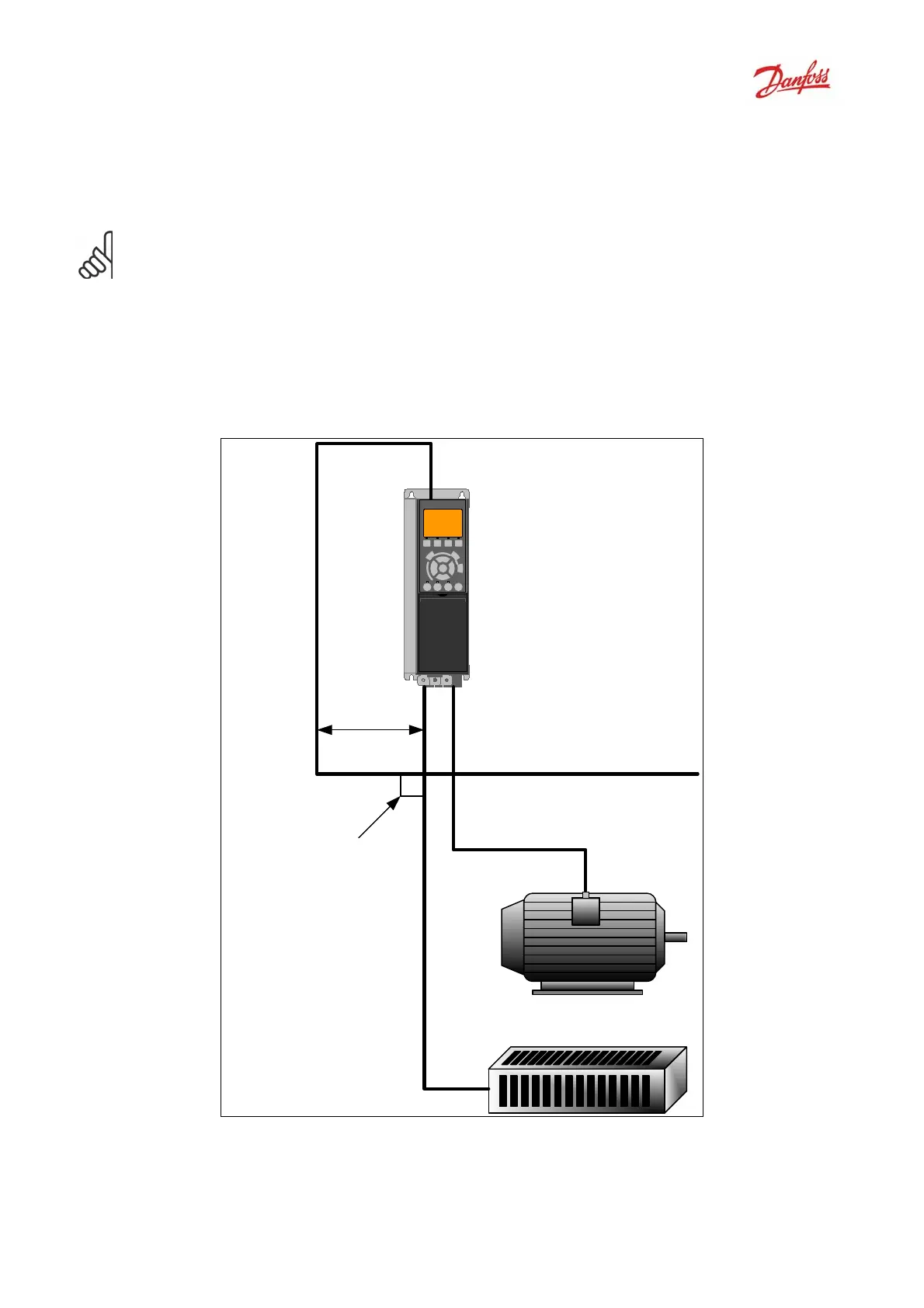

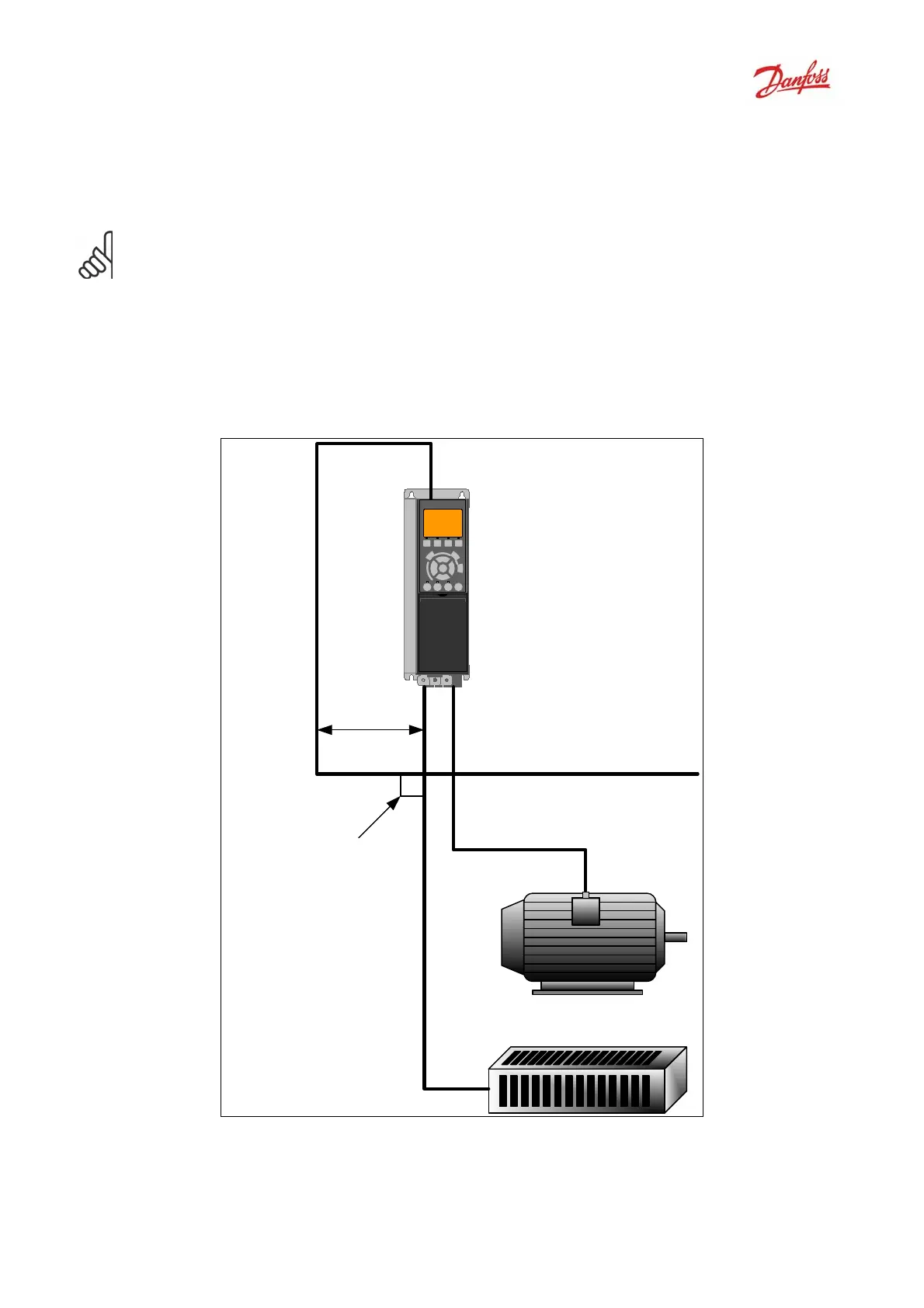

The following EMC precautions are recommended in order to achieve interference-free operation of the

Ethernet network. Additional EMC information is available in the FC 300 series Design Guide.

N.B.:

Relevant national and local regulations, for example regarding protective earth connection,

must be observed.

The Ethernet communication cable must be kept away from motor and brake resistor cables to avoid

coupling of high frequency noise from one cable to the other. Normally a distance of 200 mm (8

inches) is sufficient, but maintaining the greatest possible distance between the cables is

recommended, especially where cables run in parallel over long distances. When crossing is

unavoidable, the Ethernet cable must cross motor and brake resistor cables at an angle of 90 degrees.

AutomationDrive

VLT

min. 200 mm

90° crossing

Ethernet cable

Loading...

Loading...