VLT

®

AutomationDrive EtherNet/IP

MG.90.Jx.02 ver. 5

th

September 2007 – VLT is a registered Danfoss trademark 24

Danfoss FC Control Profile

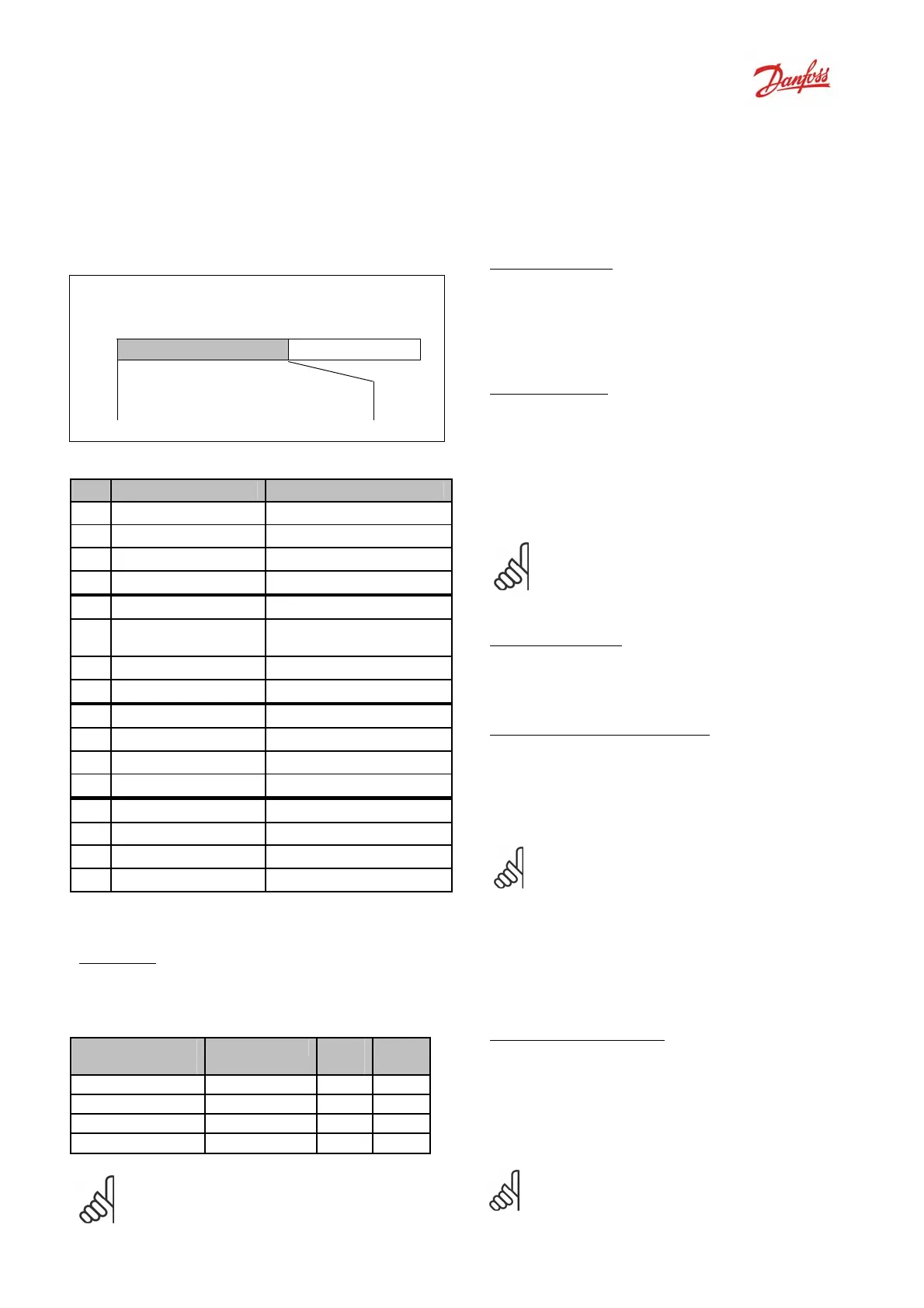

Control Word according to FC Profile.

Instances 100, 101, 103/150, 151, 153

(Par. 8-10 = FC profile)

Master → slave

CTW Speed ref.

Bit

no.:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Explanation of the Control Bits

Bits 00/01

Bits 00 and 01 are used to choose between the

four reference values, which are pre-

programmed in par. 3-10 Preset reference

according to the following table:

Programmed

ref. value

Parameter Bit

01

Bit

00

1 3-10 [0] 0 0

2 3-10 [1] 0 1

3 3-10 [2] 1 0

4 3-10 [3] 1 1

N.B.:

In par. 8-56 Preset reference select a

selection is made to define how Bit 00/01

gates with the corresponding function on the

digital inputs.

Bit 02, DC brake

:

Bit 02 = ‘0’ leads to DC braking and stop.

Braking current and duration are set in par.

2-01 DC Brake current and 2-02 DC Braking

time.

Bit 02 = ‘1’ leads to ramping.

Bit 03, Coasting

:

Bit 03 = ‘0’ causes the frequency converter to

immediately "let go" of the motor (the output

transistors are "shut off"), so that it coasts to a

standstill.

Bit 03 = ‘1’ enables the frequency converter to

start the motor if the other starting conditions

have been fulfilled.

N.B.:

In par. 8-50 Coasting select a selection is

made to define how Bit 03 gates with the

corresponding function on a digital input.

Bit 04, Quick stop

:

Bit 04 = ‘0’ causes a stop, in which the motor

speed is ramped down to stop via par.3-81

Quick stop ramp time.

Bit 05, Hold output frequency

:

Bit 05 = ‘0’ causes the present output

frequency (in Hz) to freeze. The frozen output

frequency can then be changed only by means

of the digital inputs (par. 5-10 to 5-15)

programmed to Speed up and Speed down.

N.B.:

If Freeze output is active, the frequency

converter can only be stopped by the

following:

• Bit 03 Coasting stop

• Bit 02 DC braking

• Digital input (par. 5-10 to 5-15) programmed

to DC braking, Coasting stop or Reset and

coasting stop.

Bit 06, Ramp stop/start

:

Bit 06 = ‘0’ causes a stop, in which the motor

speed is ramped down to stop via the selected

ramp down parameter.

Bit 06 = ‘1’ permits the frequency converter to

start the motor, if the other starting conditions

have been fulfilled.

N.B.:

In par. 8-53 Start select a selection is

made to define how Bit 06 Ramp

Bit

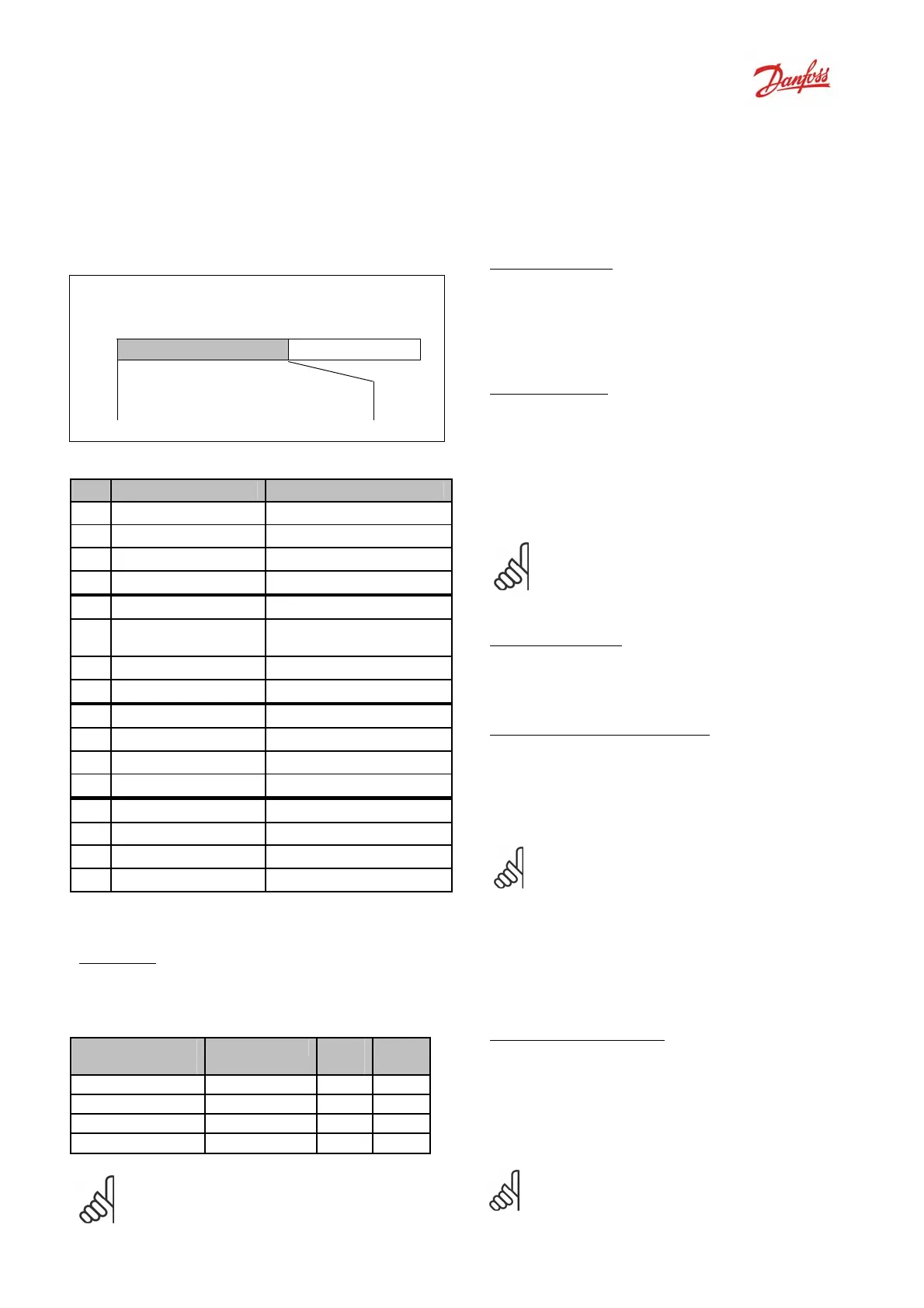

Bit value = 0 Bit value = 1

00 Reference value External selection LSB

01 Reference value External selection MSB

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05

Hold output

frequency

Use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 04 active

13 Parameter set-up Selection LSB

14 Parameter set-up Selection MSB

15 No function Reverse

Loading...

Loading...