WARNING

After installation of Safe Torque O (STO), a commis-

sioning test as specied in section Safe Torque O

Commissioning Test in the Design Guide must be

performed. A passed commissioning test is mandatory

after rst installation and after each change to the safety

installation.

Safe Torque O Technical Data

The following values are associated to the dierent types

of safety levels:

Reaction time for T37

•

Maximum reaction time: 10 ms

Reaction time = delay between de-energizing the STO

input and switching o the frequency converter output

bridge.

Data for EN ISO 13849-1

•

Performance Level "d"

•

MTTF

d

(Mean Time To Dangerous Failure): 24816

years

•

DC (Diagnostic Coverage): 99%

•

Category 3

•

Lifetime 20 years

Data for EN IEC 62061, EN IEC 61508, EN IEC 61800-5-2

•

SIL 2 Capability, SILCL 2

•

PFH (Probability of Dangerous failure per

Hour)=7e-10FIT=7e-19/h

•

SFF (Safe Failure Fraction) >99%

•

HFT (Hardware Fault Tolerance)=0 (1001

architecture)

•

Lifetime 20 years

Data for EN IEC 61508 low demand

•

PFDavg for one-year proof test: 3, 07E-14

•

PFDavg for three year proof tests: 9, 20E-14

•

PFDavg for

ve year proof tests: 1, 53E-13

No maintenance of the STO functionality is needed.

Take the necessary security measures, e.g. installation in a

closed cabinet that is only accessible for skilled personnel.

SISTEMA Data

Functional safety data is available via a data library for use

with the SISTEMA calculation tool from the IFA (Institute

for Occupational Safety and Health of the German Social

Accident Insurance), and data for manual calculation. The

library is permanently completed and extended.

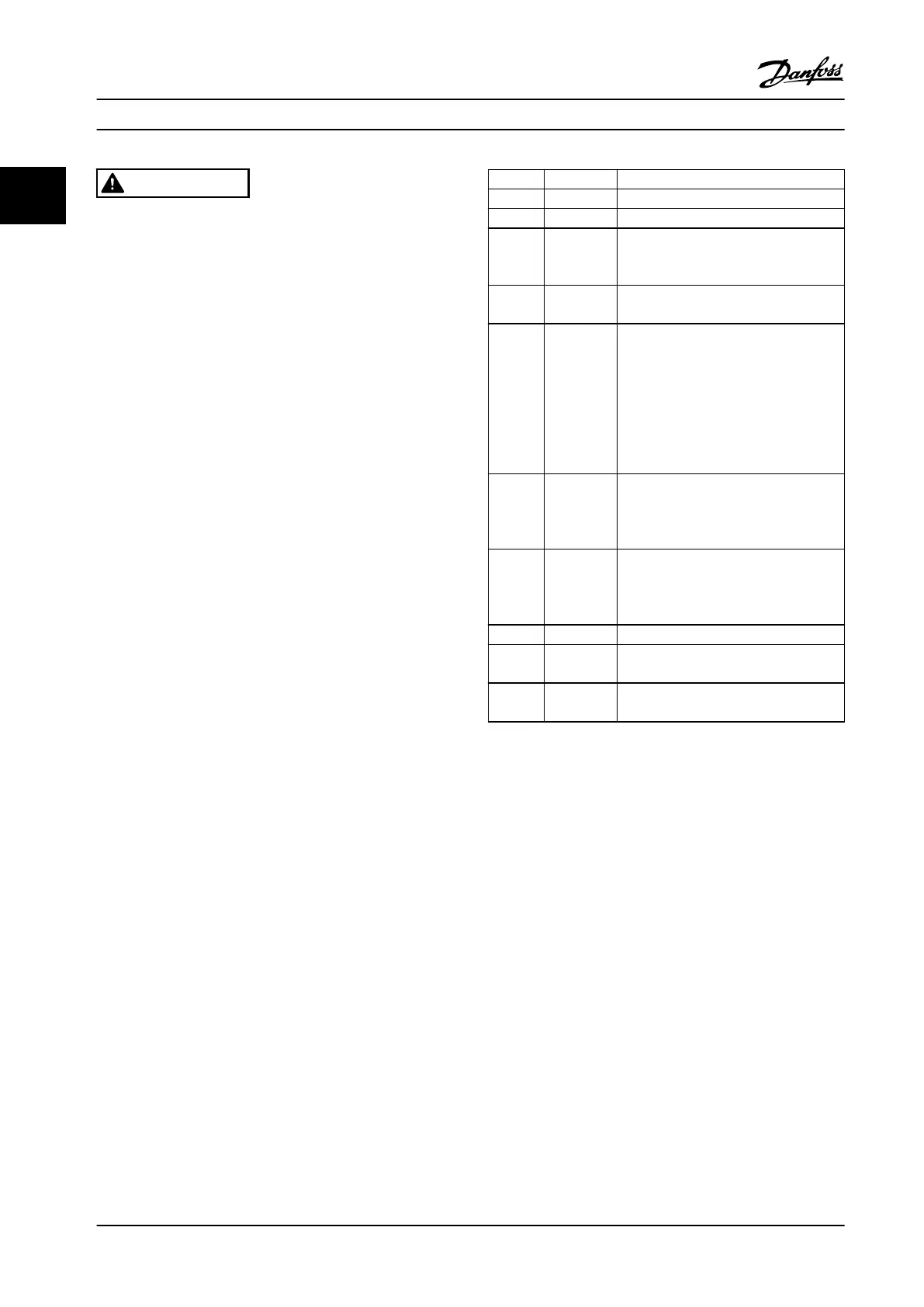

Abbrev. Ref. Description

Cat. EN 954-1 Category, level “B, 1-4”

FIT Failure In Time: 1E-9 hours

HFT IEC 61508 Hardware Fault Tolerance: HFT = n

means, that n+1 faults could cause a

loss of the safety function

MTTFd EN ISO

13849-1

Mean Time To Failure - dangerous. Unit:

years

PFH IEC 61508 Probability of Dangerous Failures per

Hour. Consider the PFH value when the

safety device is operated in high

demand (more often than once per

year); or operated in continuous mode,

where the frequency of demands for

operation made on a safety-related

system is greater than one per year.

PL EN ISO

13849-1

Discrete level used to specify the ability

of safety-related parts of control systems

to perform a safety function under

foreseeable conditions. Levels a-e.

SFF IEC 61508 Safe Failure Fraction [%]; Percentage part

of safe failures and dangerous detected

failures of a safety function or a

subsystem related to all failures.

SIL IEC 61508 Safety Integrity Level

STO EN

61800-5-2

Safe Torque O

SS1 EN 61800

-5-2

Safe Torque O 1

Table 2.1 Abbreviations Related to Functional Safety

The PFD

avg

value (Probability of Failure on Demand)

Failure probability in the event of a request of the safety

function.

2.2.1 Terminal 37 Safe Torque O Function

The frequency converter is available with Safe Torque O

functionality via control terminal 37. Safe Torque O

disables the control voltage of the power semiconductors

of the frequency converter output stage. This in turn

prevents generating the voltage required to rotate the

motor. When the Safe Torque O (T37) is activated, the

frequency converter issues an alarm, trips the unit, and

coasts the motor to a stop. Manual restart is required. The

Safe Torque O function can be used as an emergency

stop for the frequency converter. In normal operating

mode when Safe Torque O is not required, use the

regular stop function instead. When automatic restart is

used, ensure the requirements of ISO 12100-2 paragraph

5.3.2.5 are fullled.

Safety Instructions and Gen...

VLT

®

Compressor Drives CDS 302/CDS 303

8 Danfoss A/S © Rev. 2013-07-03 All rights reserved. MG34M422

22

Loading...

Loading...