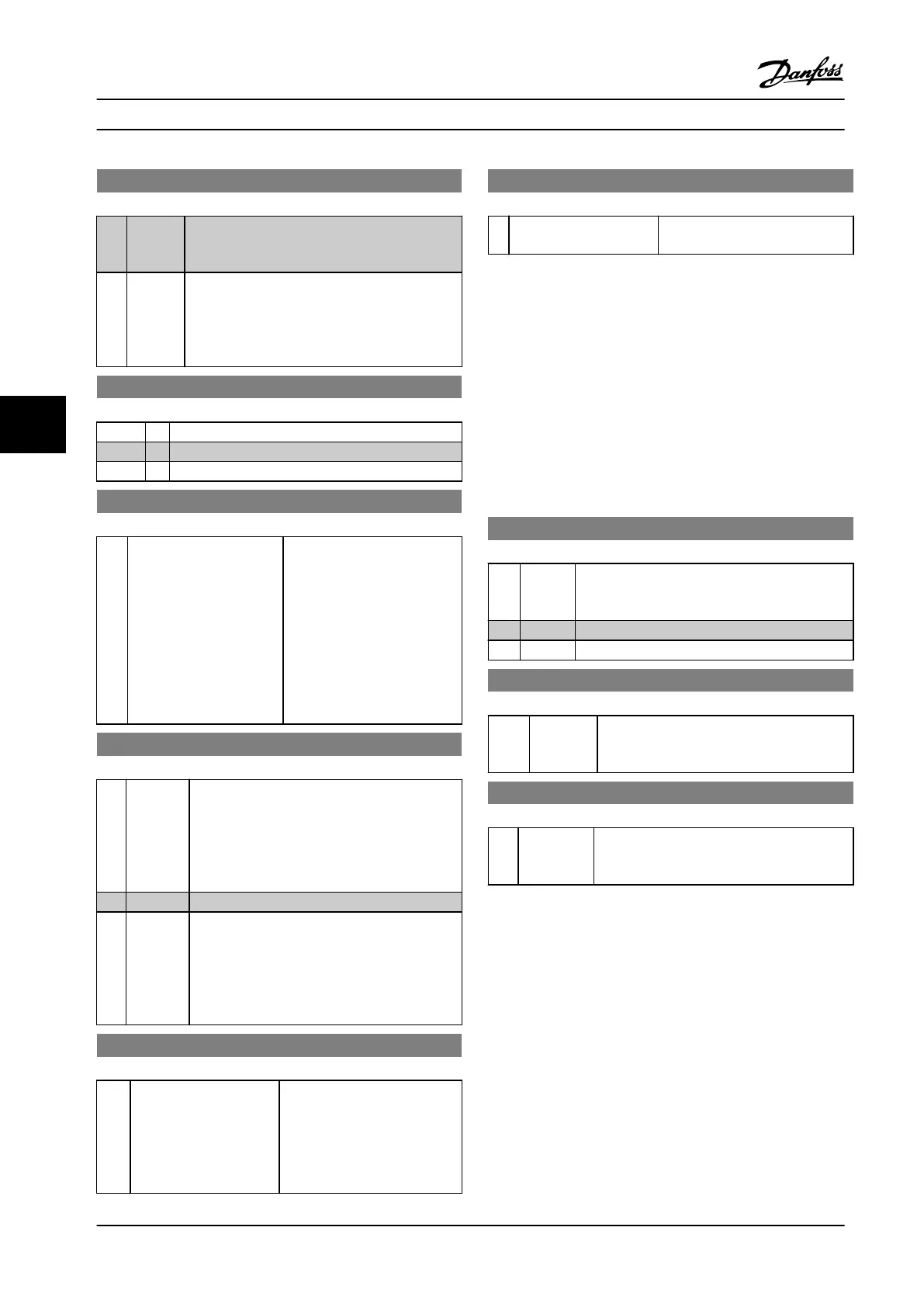

28-20 Temperature Source

Option: Function:

Low Voltage to parameter 6-25 Terminal 54 High

Ref./Feedb. Value to match the characteristics of

the device.

[3] Bus The actual discharge temperature should be sent

via Modbus RTU or FC protocol to 28-27

Discharge temperature. The temperature could be

set via PCD write in parameter 8-42 PCD Write

Conguration.

28-21 Temperature Unit

Option: Function:

Selects the unit of the discharge temperature.

[60 ] * ˚C

[160] ˚F

28-24 Warning Level

Range: Function:

130

*

[10–

parameter 28-26 Emergency

Level]

Selects the temperature at

which a warning shall be

issued. The action selected in

parameter 28-25 Warning Action

becomes active at this

temperature. Enter the

temperature measured in the

unit selected in

parameter 28-21 Temperature

Unit.

28-25 Warning Action

Option: Function:

Selects the action to be taken by the frequency

converter for discharge temperatures above the

value programmed in

parameter 28-21 Temperature Unit but below the

value programmed in parameter 28-26 Emergency

Level.

[0] None No action. Only a warning is issued.

[1]

*

Decrease

cooling

A warning is issued and the motor speed is

lowered in steps of 10 Hz every 3 minutes until

the temperature either drops below the level

programmed in parameter 28-24 Warning Level or

exceeds the level programmed in

parameter 28-26 Emergency Level.

28-26 Emergency Level

Range: Function:

145*

[parameter 28-24 Warning

Level-300]

Selects the temperature at

which an alarm shall be issued.

Enter the temperature in the

unit programmed in

parameter 28-21 Temperature

Unit.

28-27 Discharge Temperature

Range: Function:

0* [-2147483648 –

2147483648]

Returns the actual value of the

discharge temperature.

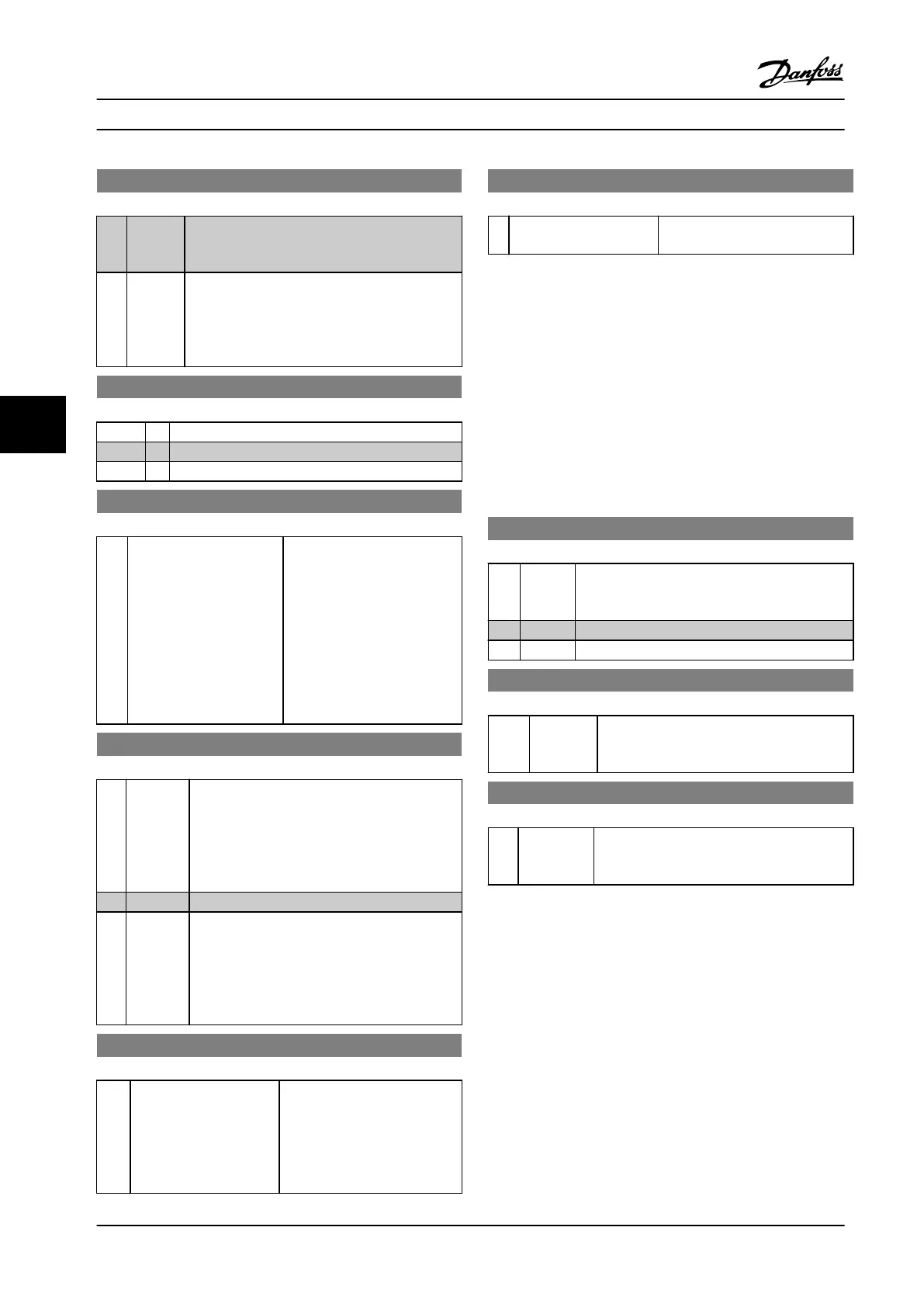

6.15.4 28-3* Crankcase Heating

A DC-hold Current through the motor windings can be

used as an alternative to an external crankcase heater to

keep the compressor warm when stopped.

The eciency of the Crankcase Heating depends upon the

physical placing of the actual motor in the compressor.

If the Crankcase Heating is used together with Anti-Reverse

Protection, the frequency converter

rst brakes for the set

duration followed by the heating current.

28-30 Crankcase Heating Control

Option: Function:

Activate the DC-hold current when the motor is

stopped. The current level is dened in

parameter 28-31 Heating DC Current.

[0] * Disabled

[1] Enabled

28-31 Heating DC Current

Range: Function:

20% * [0 – 25%] Set the DC-hold current as percentage of the

rated motor current in parameter 1-24 Motor

Current.

28-32 Crankcase Heating Delayed

Range: Function:

5 s* [5-65534 s] This time denes the delay after a stop and

until Crank Case Heating is applied to the

compressor.

6.15.5 28-4* Anti-reverse Protection

A compressor may have a preferred rotation direction and

the instructions for cabling should always be followed, but

the consequences of a reverse rotation are normally not

fatal. Set up parameter group 28-4* Anti-reverse Protection

to prevent reverse rotation at stop by injecting a DC-brake

current into the motor a few seconds after stop followed

by the eventual coast of the motor when the discharge

valve has closed.

Parameter Descriptions

VLT

®

Compressor Drives CDS 302/CDS 303

124 Danfoss A/S © Rev. 2013-07-03 All rights reserved. MG34M422

6

6

Loading...

Loading...