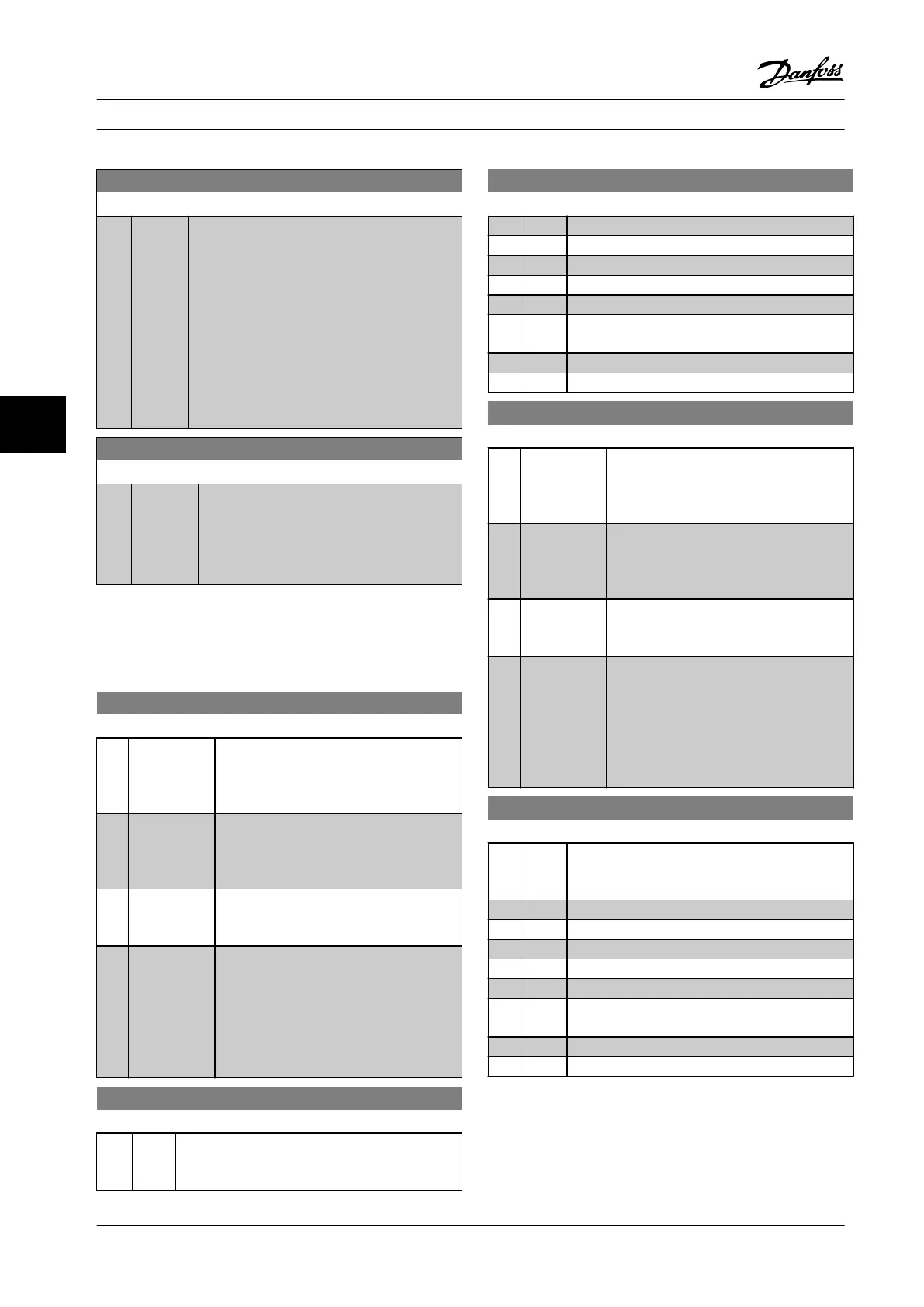

7-38 Process PID Feed Forward Factor

Range: Function:

0 %* [0 -

200 %]

Enter the PID feed forward (FF) factor. The FF

factor sends a constant fraction of the reference

signal to bypass the PID control, so the PID

control only aects the remaining fraction of the

control signal. Any change to this parameter will

thus aect the motor speed. When the FF factor

is activated it provides less overshoot, and high

dynamics when changing the set point.

parameter 7-38 Process PID Feed Forward Factor is

active when parameter 1-00 Conguration Mode

is set to [3] Process.

7-39 On Reference Bandwidth

Range: Function:

5 %* [0 -

200 %]

Enter the On Reference bandwidth. When the

PID Control Error (the dierence between the

reference and the feedback) is less than the set

value of this parameter the On Reference

status bit is high, i.e. =1.

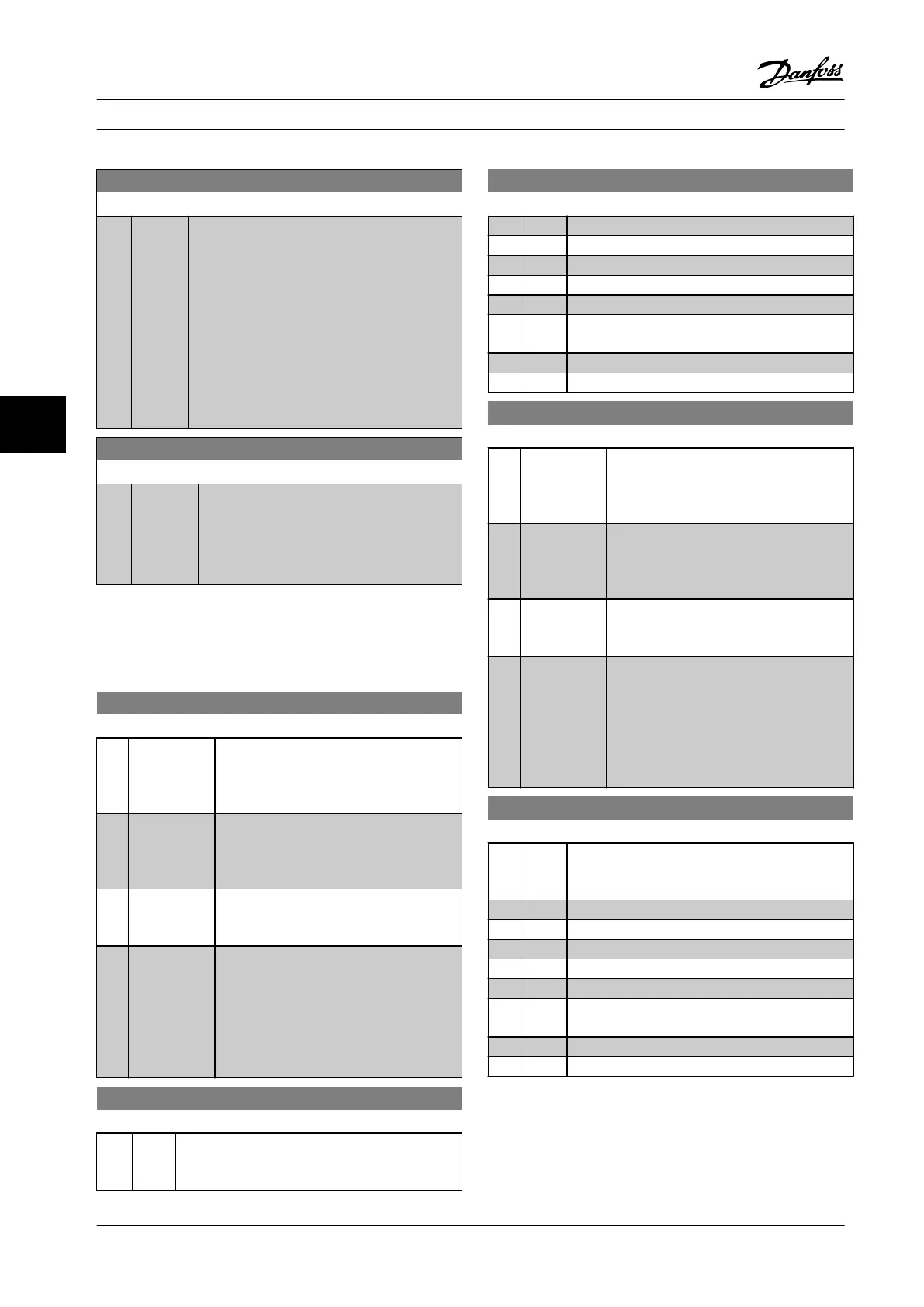

6.8.2 7-6* Feedback Conversion

Select how the signals from the feedback sources must be

converted.

7-60 Feedback 1 Conversion

Option: Function:

Selects the conversion to apply to the

feedback signal measured on the analog

input selected as feedback 1 source in 7-20

Process CL Feedback 1 Resource.

[0]

*

Linear No conversion is applied. The feedback

signal is assumed to be in the unit selected

in 3-01 Reference/Feedback Unit and enters

the process controller unchanged.

[1] Square root The square root of the feedback signal is

calculated before passing it to the process

controller.

[2] Pressure to

temperature

The feedback signal is a pressure with units

as specied in 7-61 Feedback 1 Source Unit.

It is converted to a temperature before

passing it to the process controller. The

pressure to temperature conversion is based

on the refrigerant selected in 7-70

Refrigerant.

7-61 Feedback 1 Source Unit

Option: Function:

Select the pressure unit applicable to feedback

source 1 dened in 7-20 Process CL Feedback 1

Resource.

7-61 Feedback 1 Source Unit

Option: Function:

[70] mbar

[71] bar

[72] Pa

[73] kPa

[74] m WG

[170]

[171]

psi

lb/in2

[172] in WG

[173] ft WG

7-62 Feedback 2 Conversion

Option: Function:

Selects the conversion to apply to the

feedback signal measured on the analog

input selected as feedback 2 source in 7-22

Process CL Feedback 2 Resource.

[0]

*

Linear No conversion is applied. The feedback

signal is assumed to be in the unit selected

in 3-01 Reference/Feedback Unit and enters

the process controller unchanged.

[1] Square root The square root of the feedback signal is

calculated before passing it to the process

controller.

[2] Pressure to

temperature

The feedback signal is a pressure with units

as specied in 7-62 Feedback 2 Source Unit.

It is converted to a temperature before

passing it to the process controller. The

pressure to temperature conversion is based

on the refrigerant selected in 7-70

Refrigerant.

7-63 Feedback 2 Source Unit

Option: Function:

Select the pressure unit applicable to feedback

source 1 dened in 7-22 Process CL Feedback 2

Resource.

[70] mbar

[71] bar

[72] Pa

[73] kPa

[74] m WG

[170]

[171]

psi

lb/in2

[172] in WG

[173] ft WG

Parameter Descriptions

VLT

®

Compressor Drives CDS 302/CDS 303

78 Danfoss A/S © Rev. 2013-07-03 All rights reserved. MG34M422

6

6

Loading...

Loading...