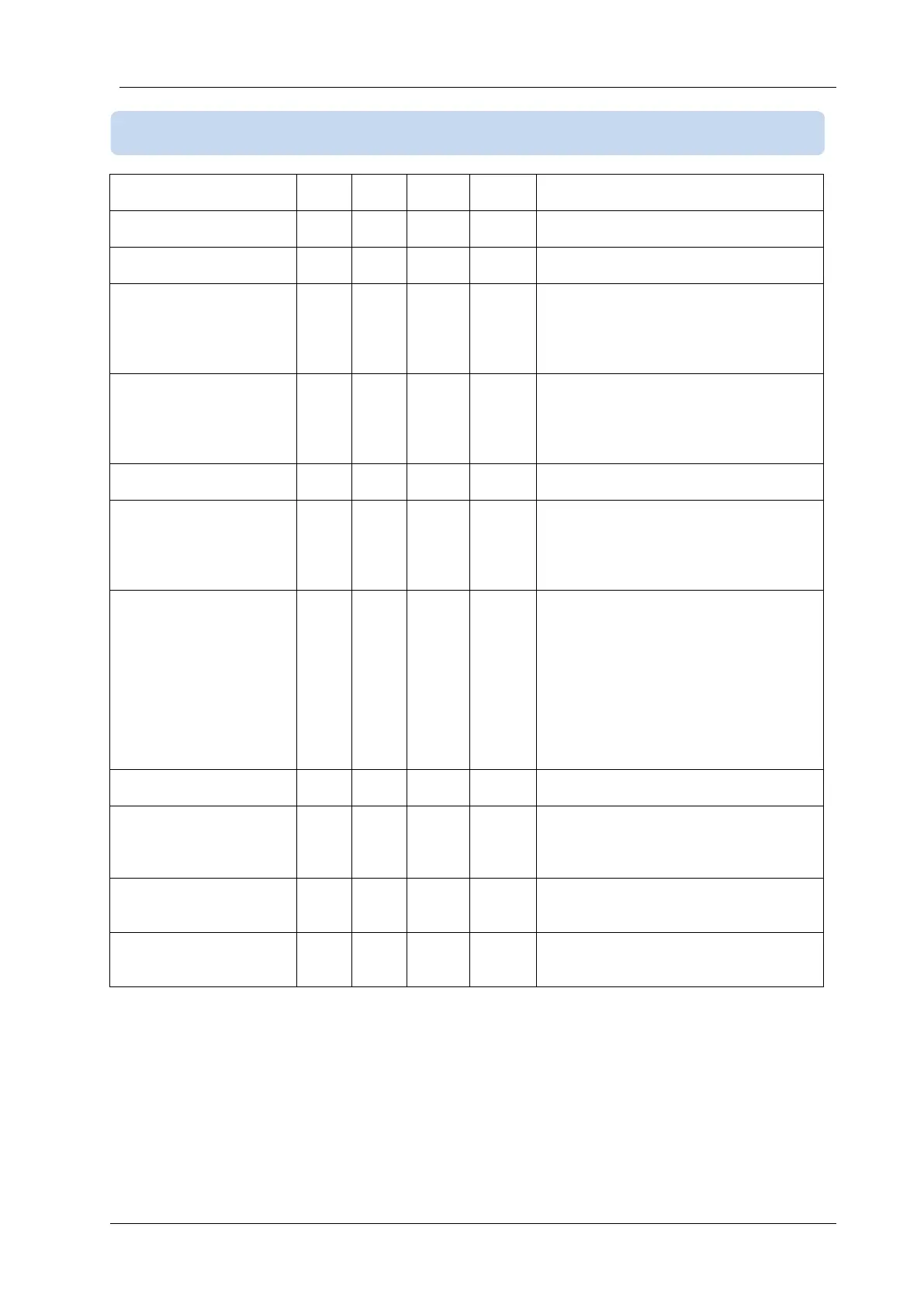

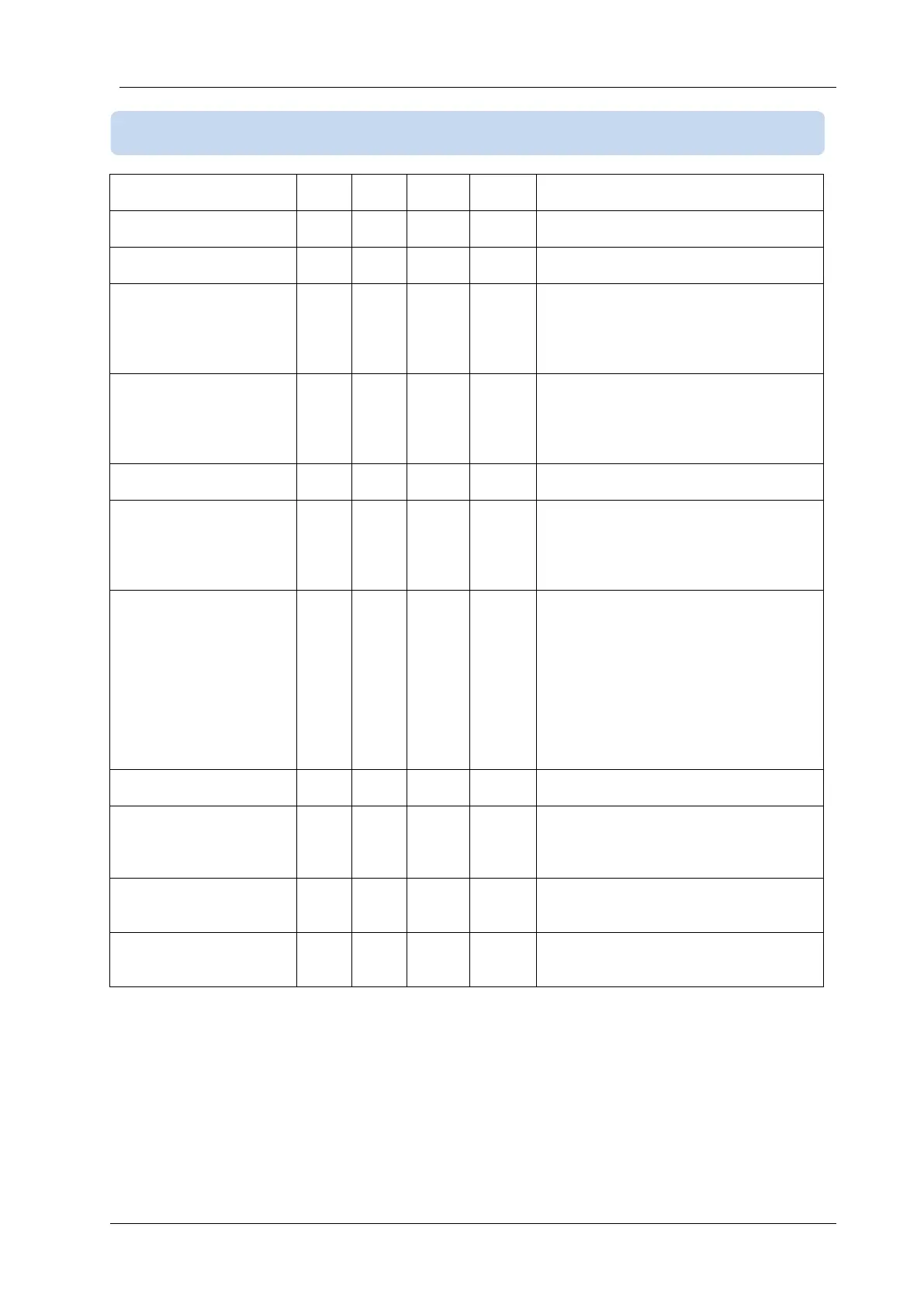

D-500L Firmware V-5.8

K35D03-EN - 76 -

This is the modbus controller identity

used in Modbus communication.

This is the data rate of the RS-485

Modbus port.

Oil Pressure Switch

Priority

0: crank cut is performed through oil

pressure switch and oil pressure sender

reading

1: crank cut is performed only through

oil pressure switch

Delayed Simulate Mains Operation:

max genset running time after Simulate

Mains signal disappears.

Dual Genset Systems: flashing relay

ON state duration timer.

Dual Genset Systems: flashing relay

OFF state duration.

This parameter trims precisely the real

time clock circuit. Values from 0 to 63

speed up the clock with 0.25sec/day

steps. Values from 127 to 64 slow down

the clock with 0.25sec/day steps.

This parameter provides the mains and

genset voltage limits with a hysteresis

feature in order to prevent faulty

decisions.

For example, when the mains are

present, the mains voltage low limit will

be used as the programmed low limit.

When the mains fail, the low limit will be

incremented by this value. It is advised

to set this value to 8 volts.

1: Engine control (no alternator)

This parameter is used for frequency to

rpm conversion. For a 1500/1800 rpm

engine select 2. For a 3000/3600 rpm

engine select 1.

RPM from genset

frequency

0: read rpm from the MPU input

1: convert frequency to rpm (using

Alternator Pole Pairs)

This is the number of pulses generated

by the magnetic pickup sensing unit in

one turn of the flywheel.

16.1. CONTROLLER CONFIGURATION GROUP (continued)

Loading...

Loading...