Neptune 5000

© Copyright Datem Limited 2014

27

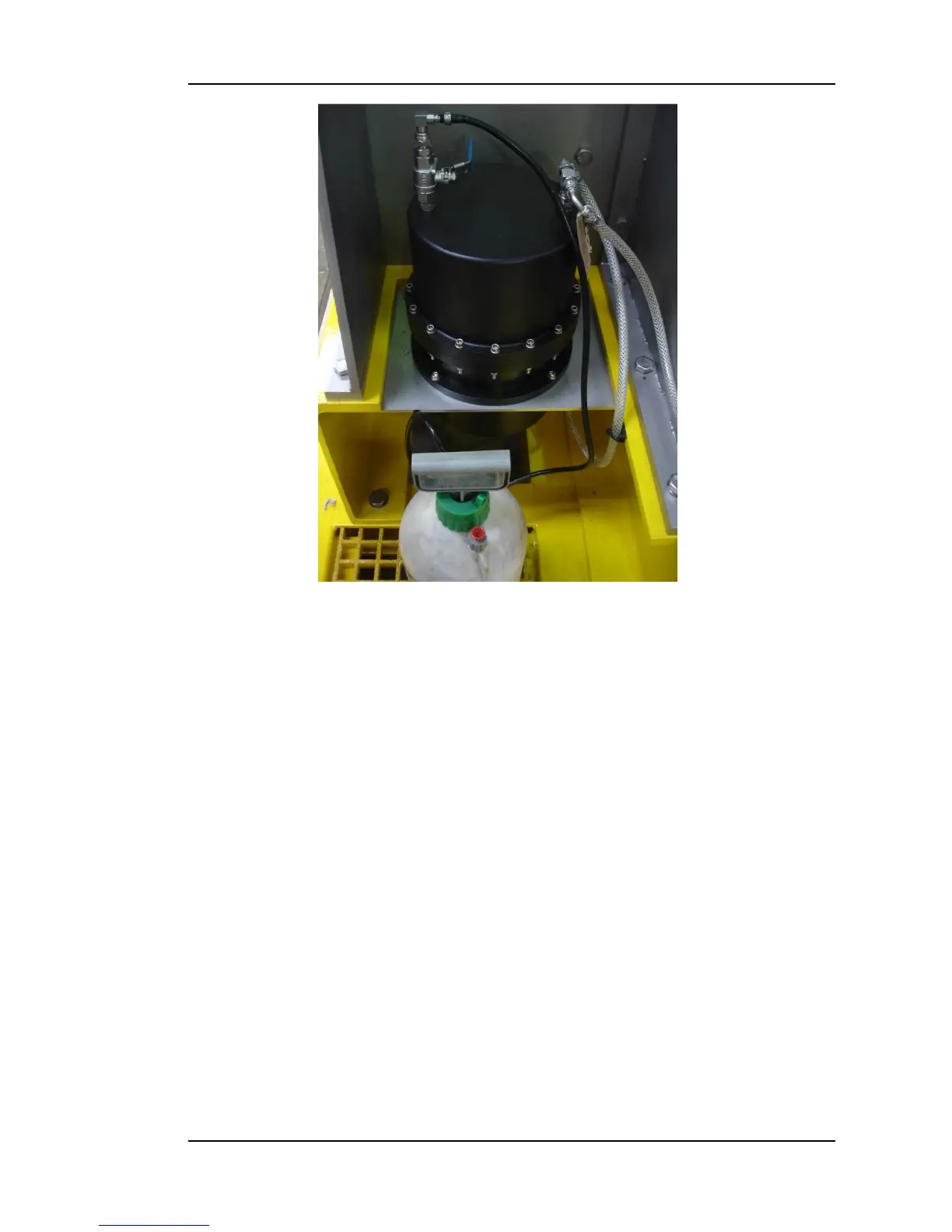

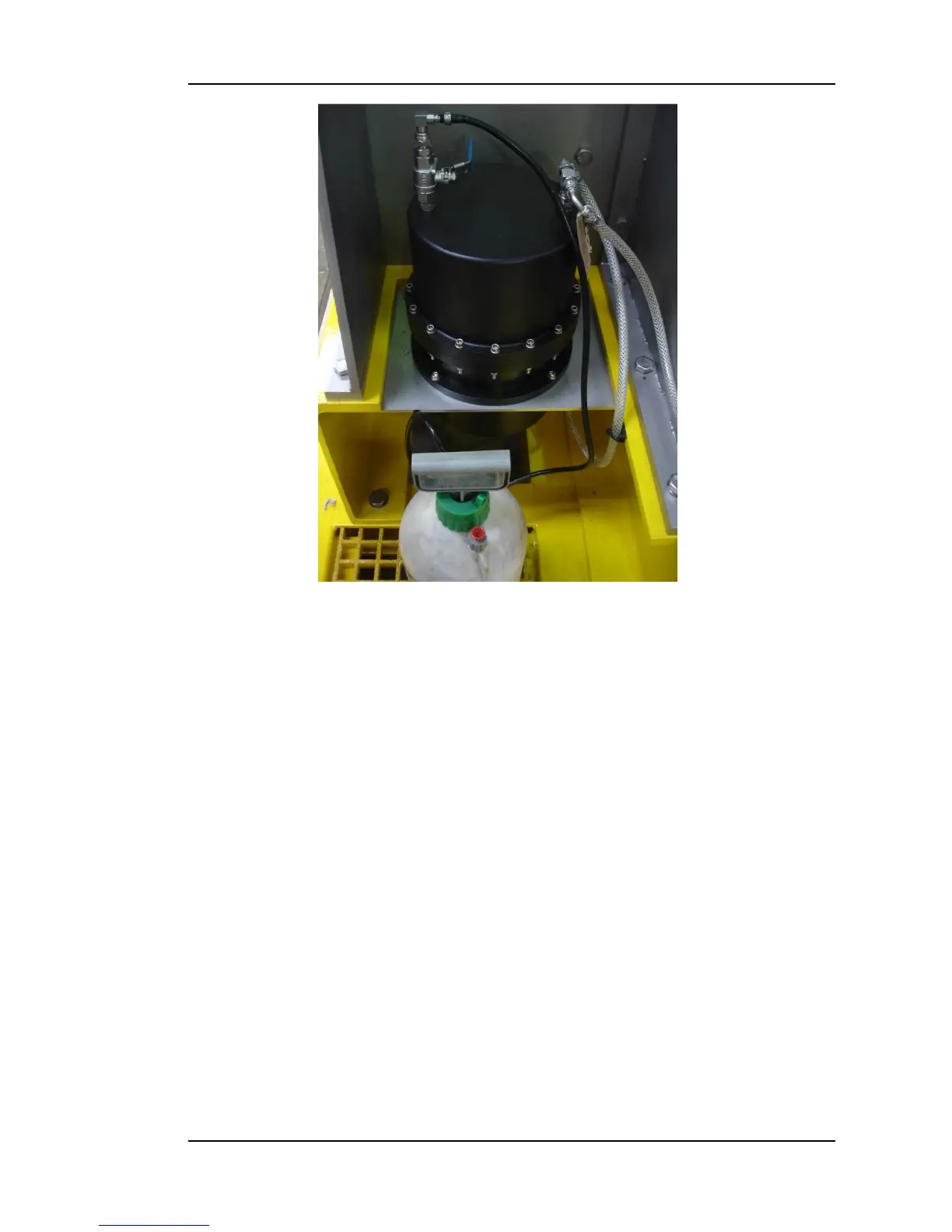

Figure 12: Pressure Compensator Connections

Ensure that the handle of the hydraulic valve fitted to the compensator is

horizontal (shown above), and hence turned off. Remove the blanking plug

that is located in the top of the hydraulic valve. Fit a drain hose to the outlet

of the hydraulic valve, and place the other end in an appropriately sized

receptacle, placed below the level of the compensator. Slowly open the

hydraulic valve. As the valve opens the oil should flow from the compensator.

The process is complete when the white coloured marker protruding from the

bottom of the compensator is barely visible, and the oil has ceased to flow

from the assembly. With the pressure released, any work carried out on the

compensator or motor requires the remaining oil to be drained from the

appropriate item.

Pressurisation

It is highly recommended to wear personal protective equipment

during the pressurisation process, in particular overalls and safety

glasses. Appropriate precautions should be taken to avoid all contact

with the oil in the pressurised system.

When pressurising the system, firstly check that all the hydraulic fittings are

tight. Fill a pressure pump with the correct oil, and attach it to the hydraulic

valve using a suitable hose. Remove the vent plug from the top of the motor

Loading...

Loading...