Multec 3.5 Fuel Injector Application Manual Product Handling

Delphi Energy and Chassis Systems

Revision: 11/05-1 6-1

6.0 Product Handling

The purpose of this section is to become familiar with the Delphi

recommended handling procedures for the Multec 3.5 Fuel Injector.

These recommendations cover storage practices and all handling that may

occur from the time the injector enters until it leaves the customer’s plant.

Use this information as a guide for product handling.

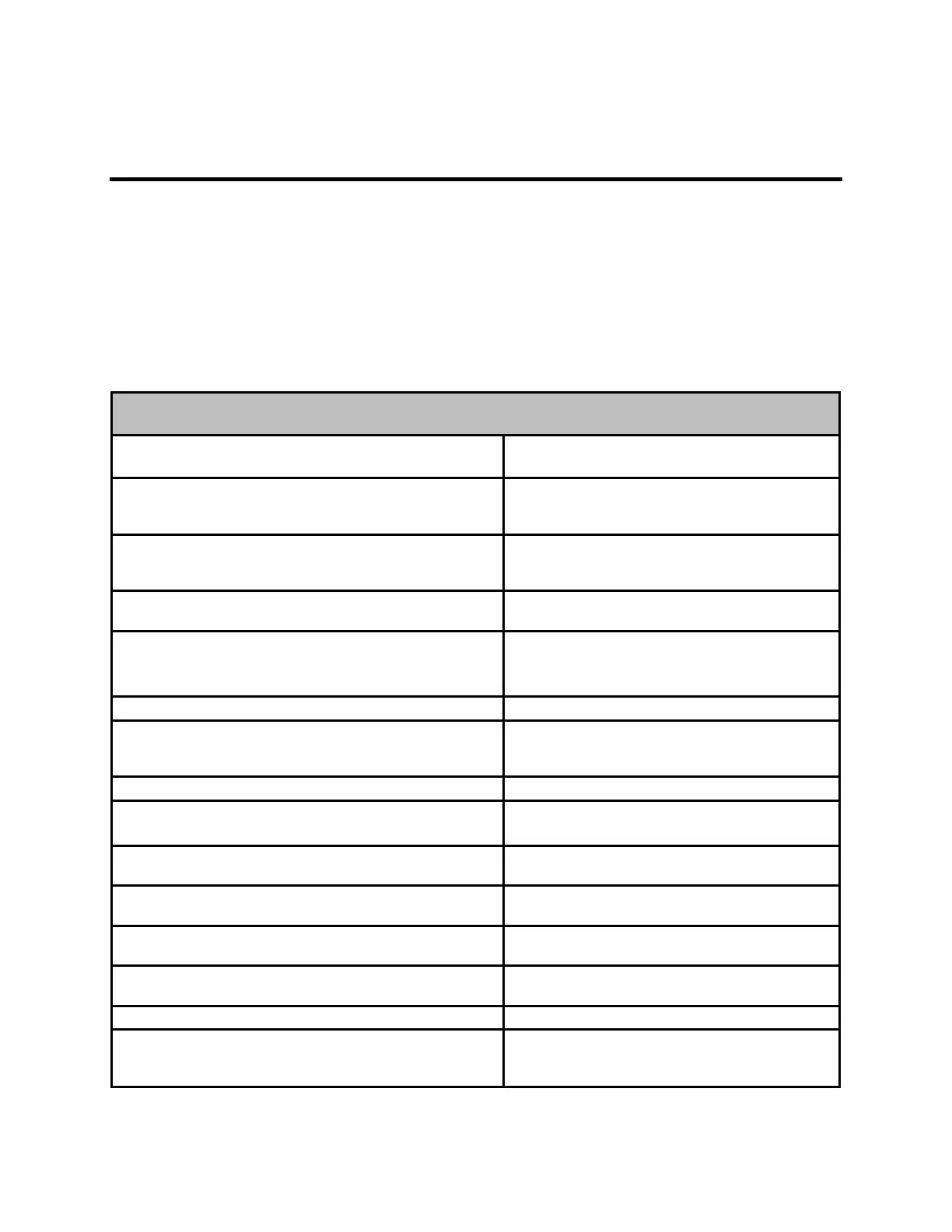

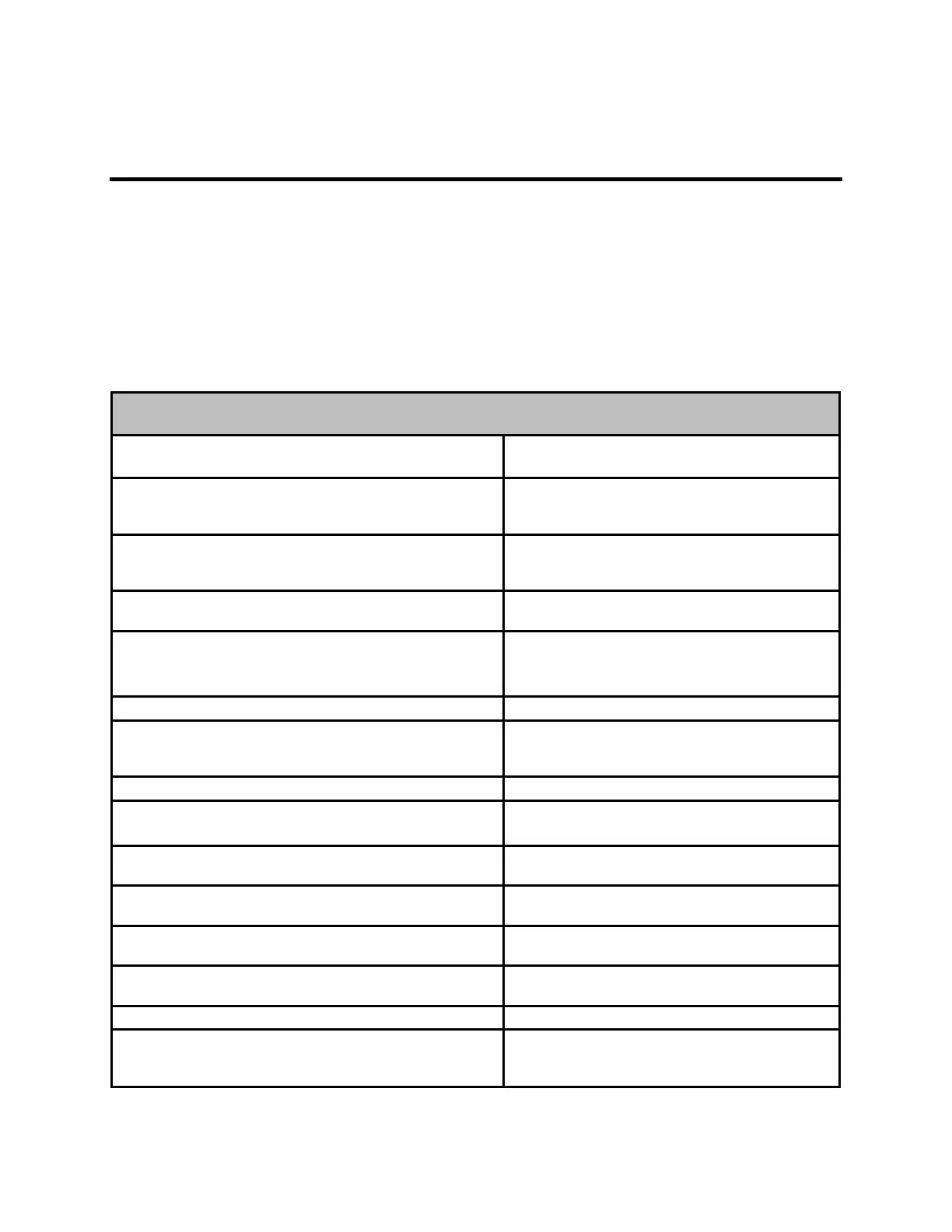

Table 6-1 lists recommendations for handling the Multec 3.5 Fuel Injector.

Table 6.1 — MULTEC 3.5 FUEL INJECTOR HANDLING

ACTION REASON

DO NOT: Re-use injector seal rings if at all possible. If no other

choice exists, take extra care in inspecting the seal rings for

damage.

Leakage.

DO NOT: Interchange seal rings from Multec 1, Multec 2 and

Multec 3.5 injectors. Use proper seal ring specified in parts listing

for the application.

Seal rings are not the same size and are not

interchangeable. Improper seal ring usage could result

in fuel leakage.

DO: Take extra care when installing new fuel seal ring over

injector inlet flange. See Figure 6-1.

Prevent tearing seal ring during installation.

DO: Use proper lubricants on seal ring surfaces to install injector

in engine. Minimize time between applying lubricant and

inserting injector / rail.

See section 6.5 for recommended lubricants.

Avoid damage to seal ring during installation.

Avoid contamination at seal.

DO NOT: Dip injector tips into lubricants.

Can plug injector spray orifices.

DO NOT: Apply voltage greater than 15V for testing. (Limit

duration to 30 sec maximum while flowing fuel, or 10 sec max

without flow).

Damage to solenoid could occur.

DO NOT: Cycle injector repeatedly without fuel pressure.

Damage to internal mechanical components.

DO: Pulse (actuate) stuck closed or tip-leak suspected injector

(Actuate consists of one pulse <5 sec duration at 9 to 15V).

To verify the injector failure (See section 3.11).

DO NOT: Pulse (actuate) a suspected high leak rate injector (leak

>50 sccm air).

Can dislodge internal contamination if present and

preclude root cause analysis.

DO: Pulse (actuate) injectors prior to a dry fuel system leak test at

engine/vehicle assembly to reseat injector valves.

Injector valves may not reseat without fuel after shipping

and handling resulting in false leakage.

DO NOT: Use “snoop” or equivalent, to leak check injector.

Can cause soap deposits on injector. Use Stoddard

solvent or Delphi approved equivalent.

DO NOT: Allow water to enter fuel system from air lines, etc.

during leak checks.

Can damage injectors.

DO: Avoid any liquid contamination in the injector area.

Coil could short circuit.

DO NOT: Use any Dupanol or any material containing water on

fittings on any area that could cause water to travel into the

injector

Can cause injector to rust or stick.

Loading...

Loading...