Fundamentals Multec 3.5 Fuel Injector Application Manual

2-6 Delphi Energy and Chassis Systems

Revision: 11/05-1

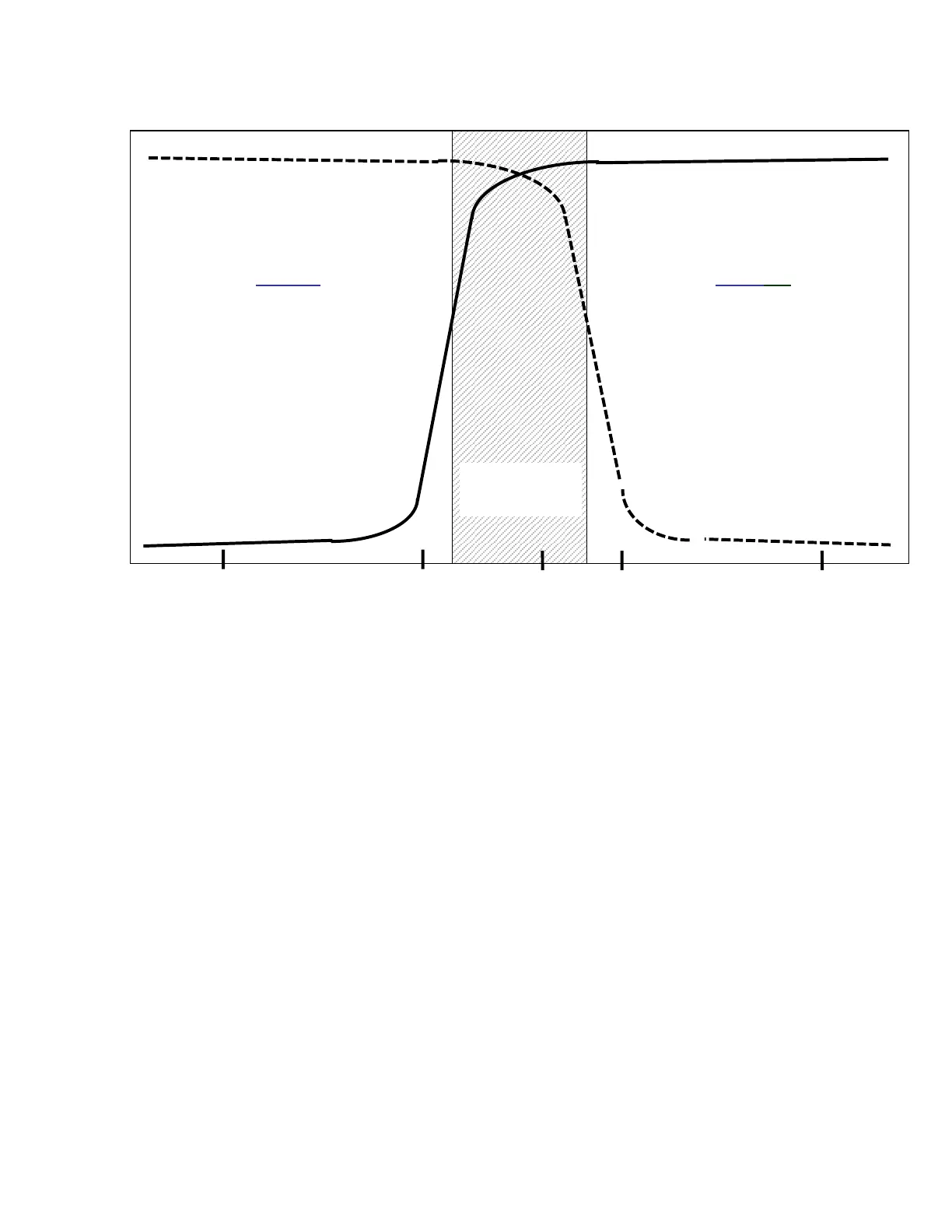

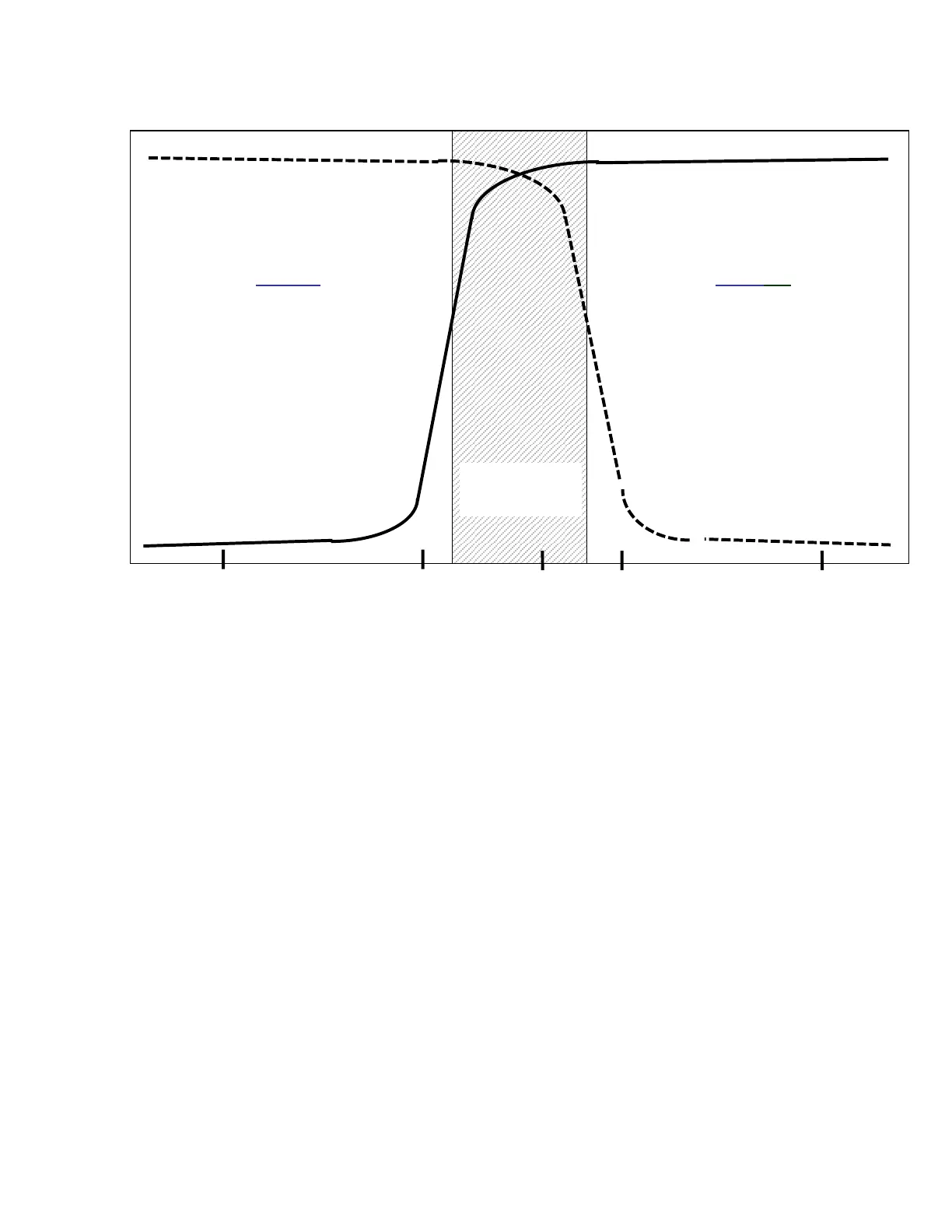

Figure 2-2 - Air Fuel Ratio Effect on Catalytic Converter Efficiency

2.2.1.4 Lean Mixtures

• A mixture with "excess air"; also described by a Lambda >1.00 or an

equivalence ratio <1.00

Lean mixtures have excess oxygen and higher combustion temperatures

resulting in increased oxides of nitrogen (NO

x

) emissions. Nitric oxide

(NO) is the primary oxide created. It forms at a significant rate when

combustion chamber temperatures are above 1200

o

F (650

o

C.) The rate

of NO

x

formation increases with excess oxygen concentration,

temperature and time at temperature. NO

x

is typically highest just lean of

stoichiometry. Lean mixtures above a 16 – 17 to 1 air/fuel ratio decrease

NO

x

production due to the lowering of combustion temperatures.

While NO

x

production is an undesirable product of running slightly lean,

there are several benefits that can be realized by running lean of

stoichiometry. A controlled lean combustion process can reduce the

output of hydrocarbon (HC) and carbon monoxide (CO) emissions, as well

as reducing fuel consumption. Diluting the intake charge with a non-

Conversion Efficiency for a Typical Three-Way Catalyst

NO

CO

Air/Fuel Ratio

Lean Region: where excess O

2

is

available to oxidize HC & CO.

(Oxidizing means adding oxygen)

Rich Region: where little O

2

is

available, so reduction can easily

be done to NO

X

. (Reduction

means stripping away oxygen)

100

80

60

40

13.0 14.0 14.6 15.0 16.0

Window

+/- 0.3

Loading...

Loading...