Validation Requirements Multec 3.5 Fuel Injector Application Manual

9-4

Delphi Energy and Chassis Systems

Revision: 11/05-1

The requirements in this section relate to testing performed in the course of

injector validation for structural integrity, fuels compliance, and injector

flow performance over anticipated service life. All testing, unless otherwise

noted, should be performed using Delphi test procedures.

Multec 3.5 will be validated for durability flow performance on a number of

fuels that are arrived at through Customer request or market analysis. While

it is difficult to validate for every fuel available in the marketplace, the list

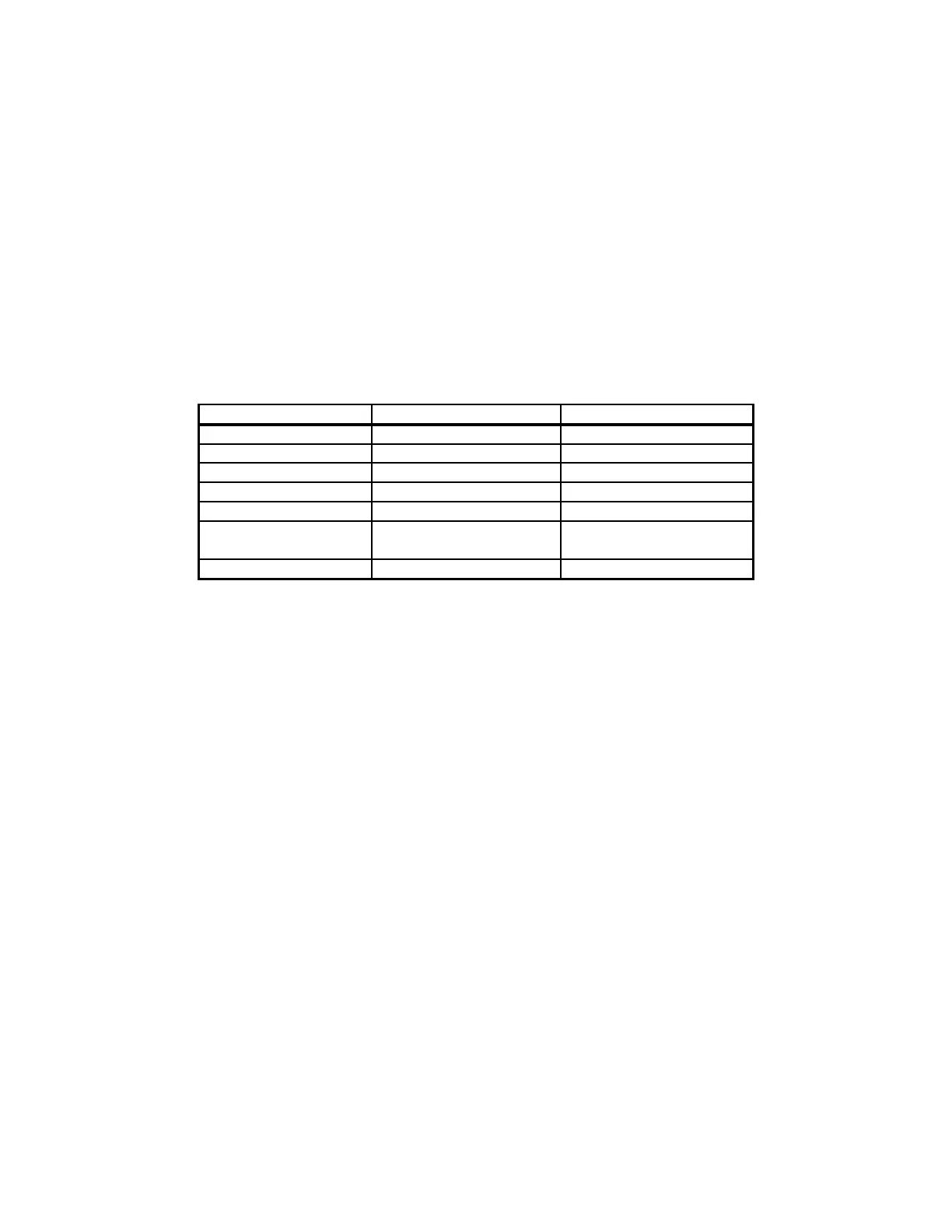

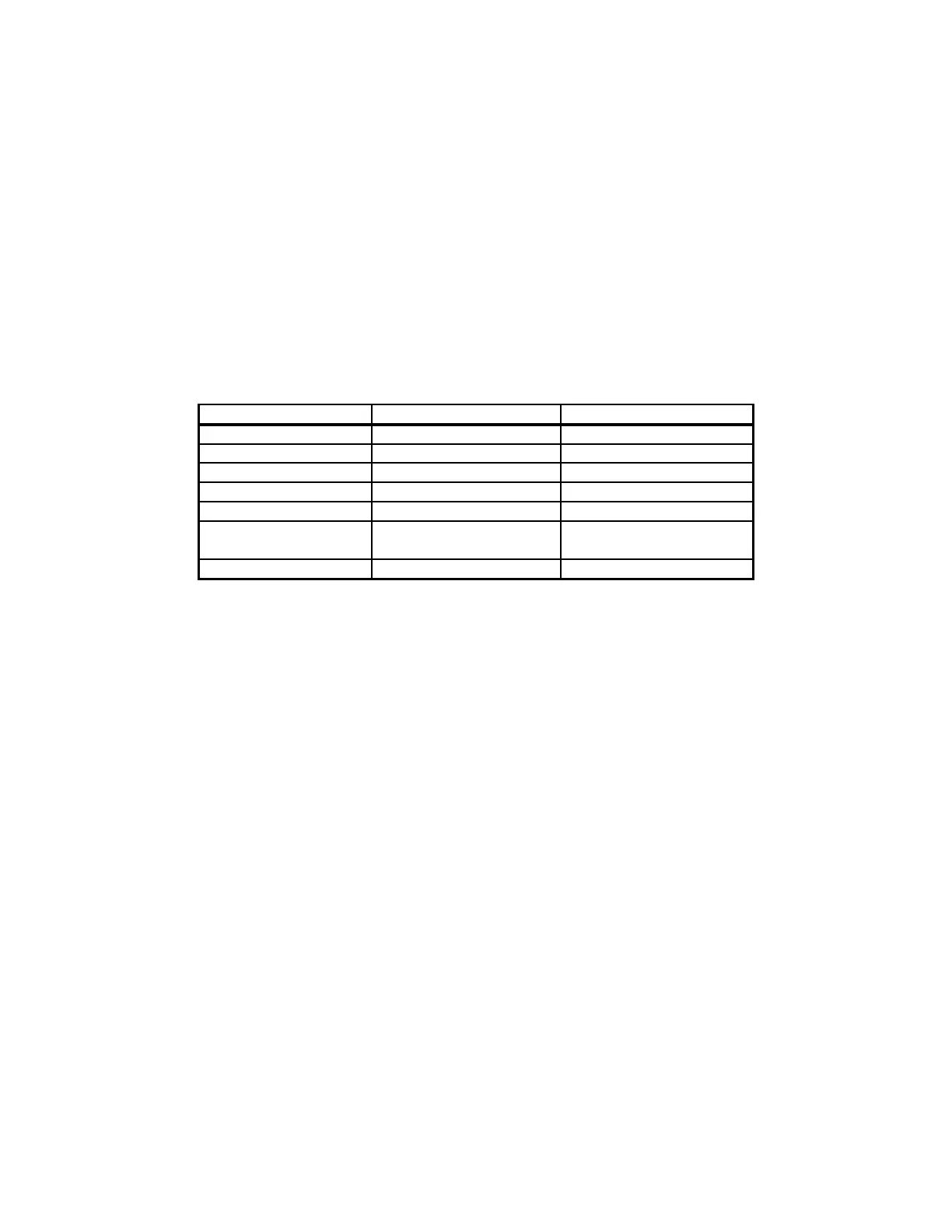

of validation fuels, shown in Table 9-1, is intended to be comprehensive,

and cover all but the most severe fuels, for which additional design

measures may be required.

In some cases engineering and materials analyses will be used in place of

physical testing to verify compatibility with certain fuels in Table 9-1.

Table 9-1 - Potential Injector Test Fuels

9.3.4 Mechanical Integrity

Mechanical integrity testing consists of monitoring injector performance and

physical condition after exposure to forces that may be encountered in actual

field use. Exposures to these forces will not cause injector flow shift

exceeding the limits defined on the Injector Outline Drawing, or result in

unacceptable physical alteration or damage.

(Reference section 5.8 of SAE J1832)

9.3.4.1 Structural Tests

Multec 3.5 injectors will meet flow shift requirements per the Injector

Outline Drawing after the following structural tests:

9.3.4.2 Axial Force

Apply 800 N compressive and tensile to the injector between the injector tip

and the end of the fuel inlet. For the tensile test the load may be applied at

the shoulder of manifold seal ring gland and to the upper seal ring retainer.

Fuel Description Comments

TF1 E10 Non Corrosive

TF3 15% MTBE

Phase II CARB Spec with MTBE

Peroxide Fuel Mix Fuel "C" + Peroxides

Corrosive NAE10 E10 + Corrosive Pkg

Brazilian E20

Fuel "C", E20 - 24 +

Corrosive pkg.

E22 Commonly used

Delphi Plugging Fuels Delphi Formulation For plugging test

Loading...

Loading...